Large-dimension aromatic ring structure-containing polyester for powder coating and preparation method of polyester

A powder coating, large-scale technology, applied in the direction of powder coatings, epoxy resin coatings, polyester coatings, etc., can solve the limited ability of molecular bond rotation and thermal movement, the limited improvement of polyester resin heat resistance, powder It is difficult to improve the heat resistance of coatings and other problems, and achieve the effect of solving heat resistance and melt processing processability, low melt viscosity and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

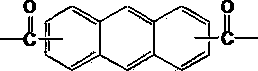

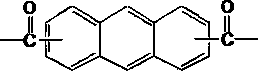

Image

Examples

Embodiment 1

[0019] Add 40 g of neopentyl glycol, 12 g of ethylene glycol, and 0.5 g of water into a 250 mL four-neck flask equipped with a mechanical stirrer, thermometer, rectification tube, vacuum and nitrogen introduction device, heat to 100 ° C and stir for 30 min. Add 26 g of dimethyl 1,8-anthracene dicarboxylate, 11 g of terephthalic acid, 6 g of isophthalic acid, and 1.5 g of adipic acid, stir and mix, and appropriately increase the nitrogen gas intake. 0.2 g of dibutyltin oxide was added, and the temperature was raised to 130° C. It was found that water generated by the esterification reaction was produced. When the esterification rate reaches about 95%, the acid value of the system reaches 15 mgKOH / g, vacuumize for polycondensation reaction; when the esterification rate reaches 5mgKOH / g, the softening point is around 100°C, add 2g of isophthalic acid for acidolysis reaction , when the acid value reaches 60-65 mgKOH / g, vacuumize for the second time, the reaction system ester reach...

Embodiment 2

[0021] Add 35 g of neopentyl glycol, 17 g of ethylene glycol, and 0.5 g of water into a 250 mL four-necked flask equipped with a mechanical stirrer, thermometer, rectification tube, vacuum and nitrogen introduction device, heat to 100 °C and stir for 30 min. Add 20 g of dimethyl 1,8-anthracene dicarboxylate, 8 g of terephthalic acid, 14 g of isophthalic acid, and 0.5 g of adipic acid, stir and mix, and appropriately increase the nitrogen gas intake. 0.5 g of dibutyltin oxide was added, and the temperature was raised to 130° C. It was found that water generated by the esterification reaction was produced. When the esterification rate reaches about 95%, the acid value of the system reaches 15 mgKOH / g, vacuumize for polycondensation reaction; when the esterification rate reaches 5mgKOH / g, the softening point is around 100°C, add 3g of isophthalic acid for acidolysis reaction , when the acid value reaches 60-65 mgKOH / g, vacuumize for the second time, the reaction system ester reac...

Embodiment 3

[0023] Add 20 g of neopentyl glycol, 21 g of ethylene glycol, and 0.8 g of water into a 250 mL four-necked flask equipped with a mechanical stirrer, a thermometer, a rectifying tube, a vacuum and nitrogen introduction device, heat to 100 °C and stir for 30 min. Add 15 g of dimethyl 1,8-anthracene dicarboxylate, 7 g of terephthalic acid, 12 g of isophthalic acid, and 2 g of adipic acid, stir and mix, and appropriately increase the nitrogen gas intake. 1.5 g of dibutyltin oxide was added, and the temperature was raised to 130° C. It was found that water generated by the esterification reaction was produced. When the esterification rate reaches about 95%, the acid value of the system reaches 15 mgKOH / g, and the polycondensation reaction is carried out by vacuuming; when the esterification rate reaches 5 mgKOH / g, the softening point is around 100°C, and 5 g of isophthalic acid is added for acidolysis reaction , when the acid value reaches 60-65 mgKOH / g, vacuumize for the second ti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com