Presser foot independent driving mechanism for embroidery machine

An independent drive, embroidery machine technology, applied to the mechanism of embroidery machines, embroidery machines, textiles and papermaking, etc., can solve the problems of long embroidery time, poor embroidery quality, impracticality, etc., to improve embroidery speed and ensure Embroidery quality, movement with good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

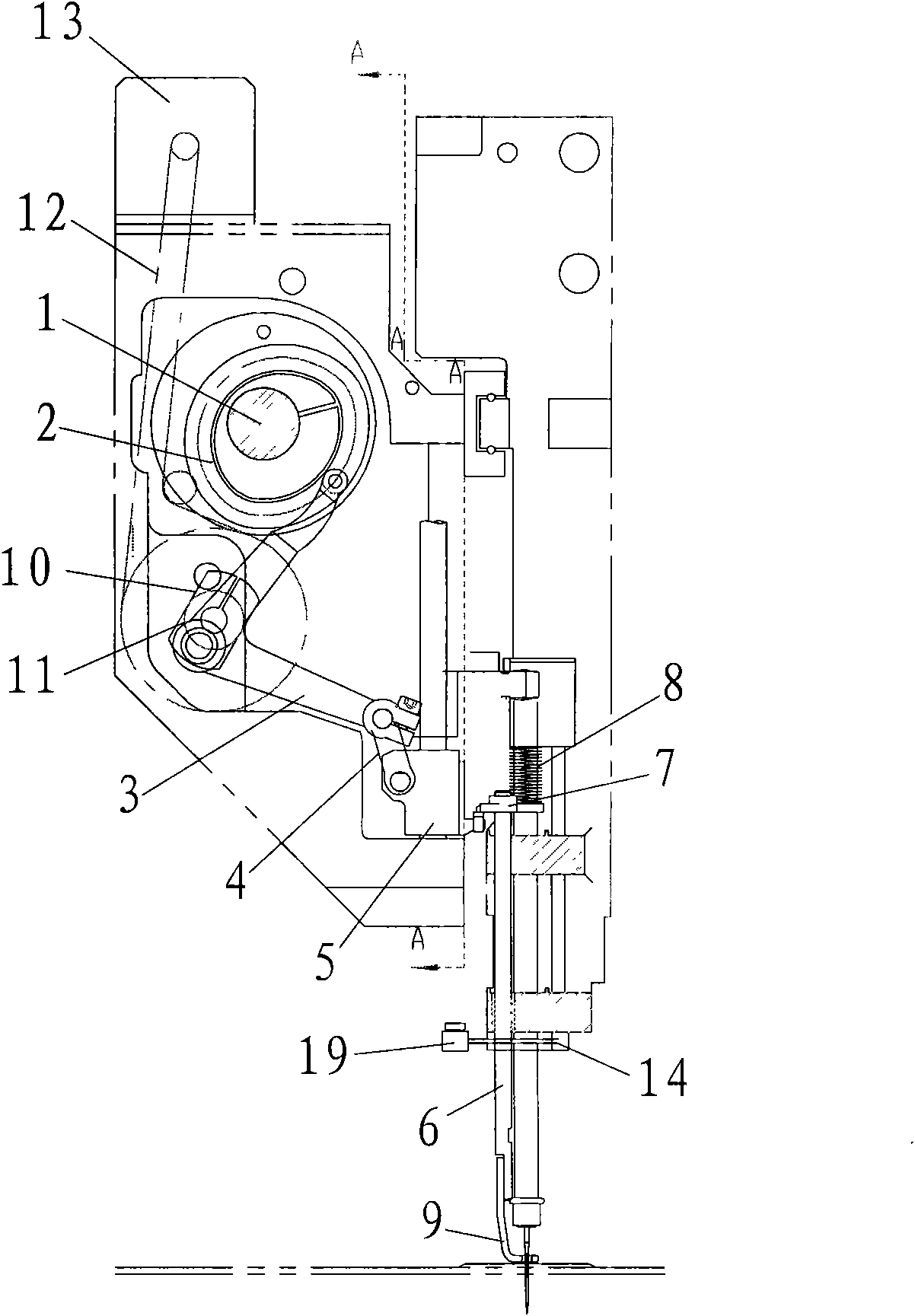

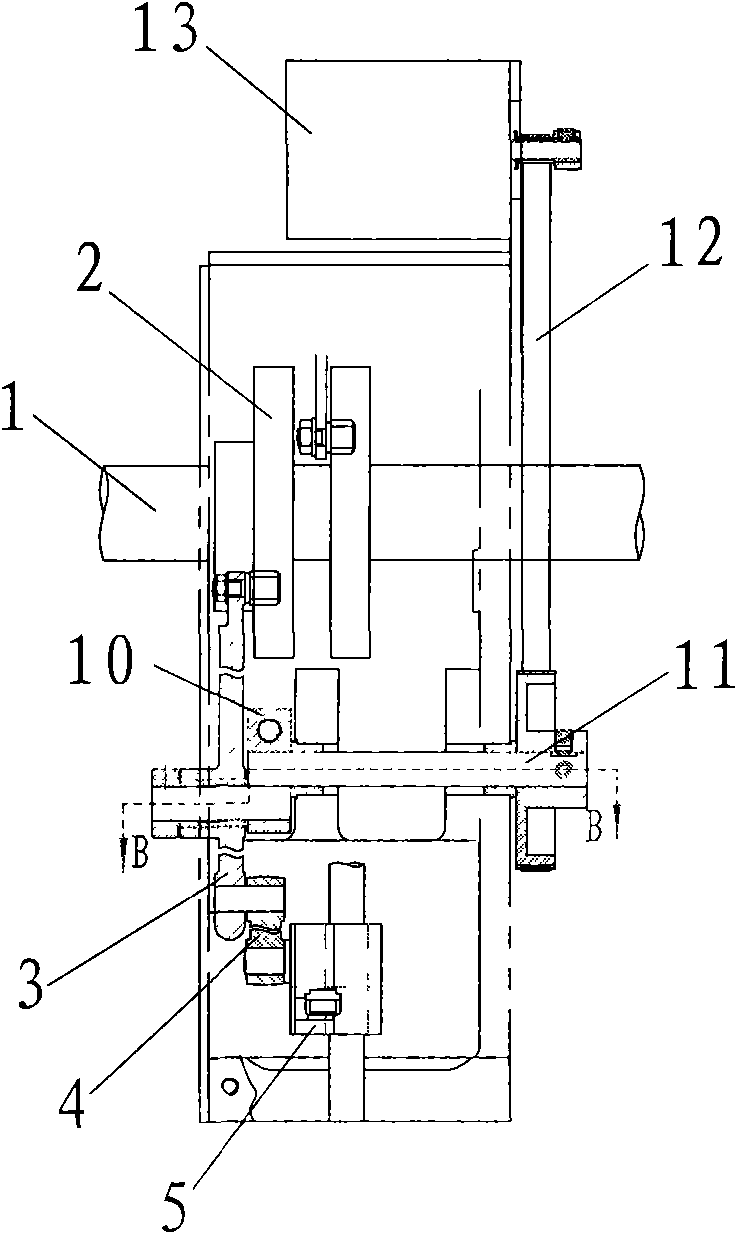

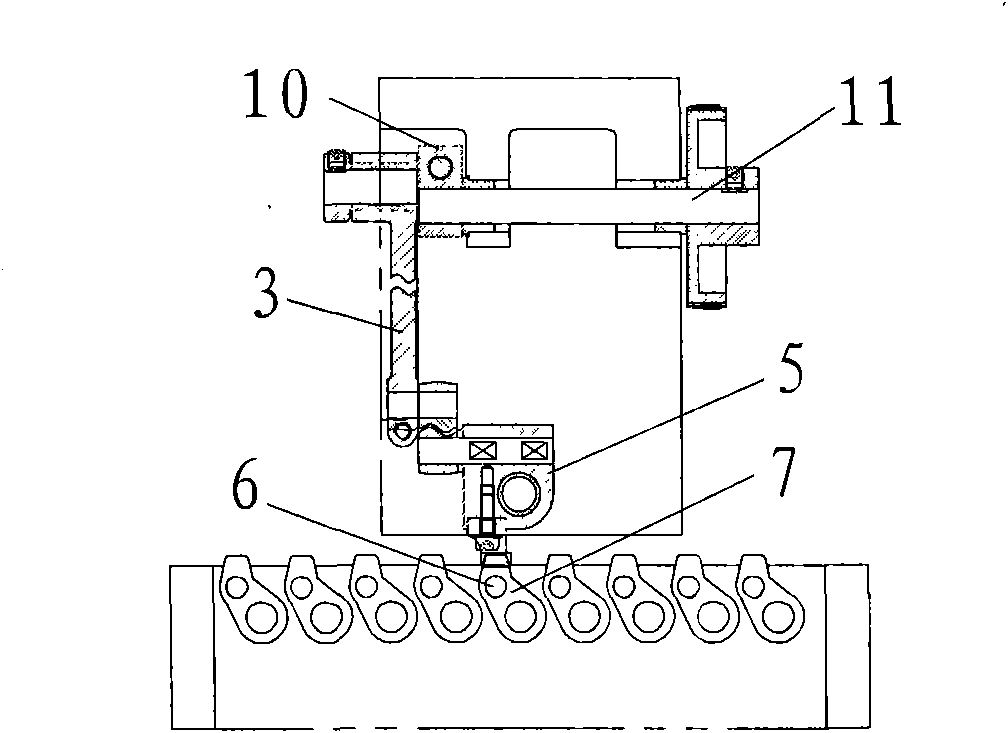

[0022] refer to Figure 1 to Figure 5 , embroidery machine presser foot independent drive mechanism, including:

[0023] A transmission main shaft 1 installed horizontally on the embroidery machine, and a driving device drives the transmission main shaft 1 to rotate;

[0024] A presser foot cam 2, the presser foot cam 2 is arranged in the head of the embroidery machine, and is set on the transmission main shaft 1, the said presser foot cam 2 is connected with a rocker arm 3, and the rocker arm 3 connects with the small connecting rod 4 The presser foot drive slider 5 is movably connected;

[0025] A presser foot bar 6 arranged on the head of the embroidery machine, the top of the presser foot bar 6 is fixedly fitted with a connecting seat 7 with double holes, and a needle bar is set in the other hole of the connecting seat 7, and the top of the needle bar A needle bar joint is provided, and a spring 8 is placed outside the needle bar. The spring 8 is located between the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com