Machine for producing decorated loom-woven fabrics

a technology of loom weaving and machine, which is applied in the direction of embroidering machine, automatic machine, embroidering machine, etc., can solve the problems of wasting the corresponding head weave and selvage, affecting the overall production cost of these products, and high fabric waste, etc., to achieve high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

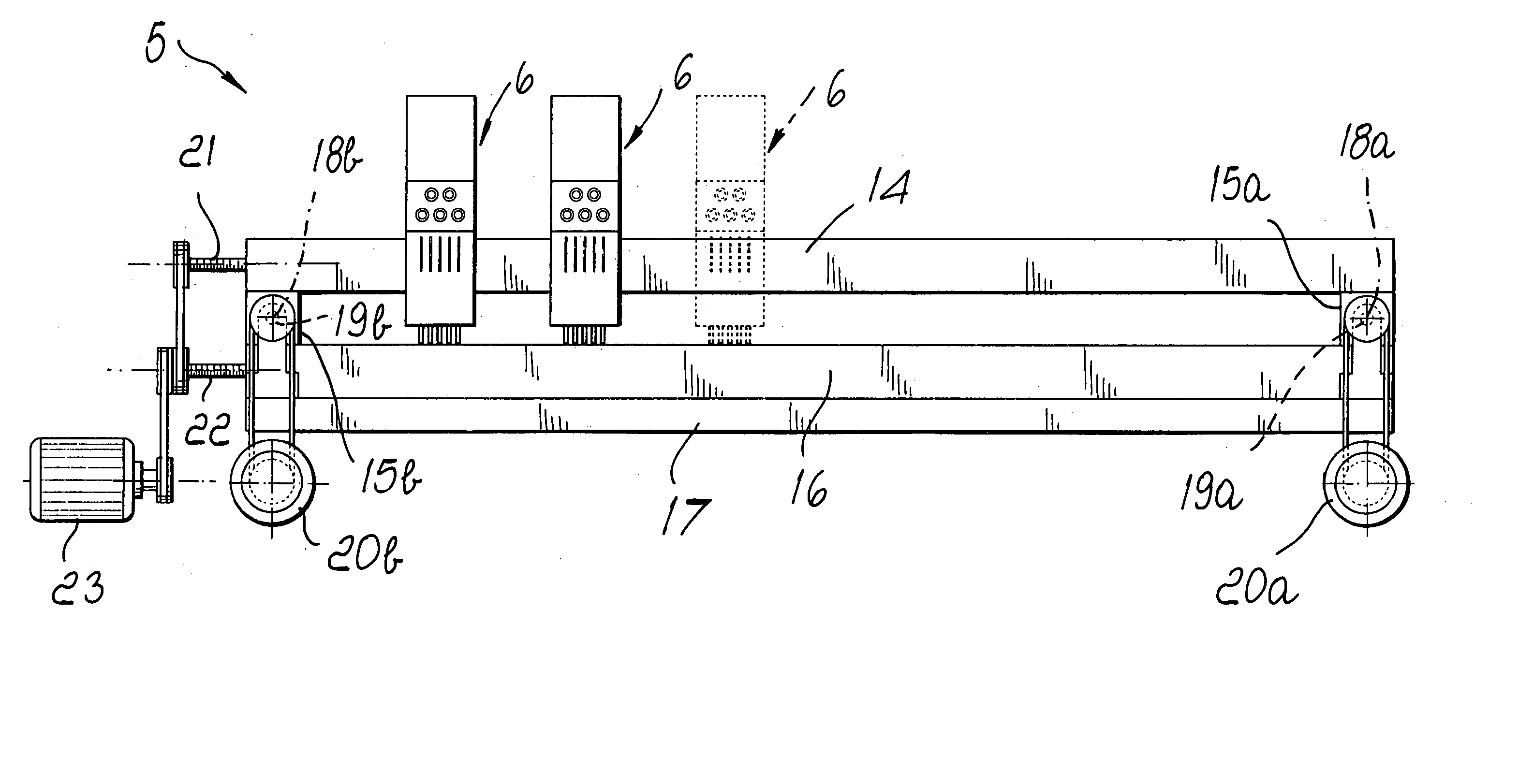

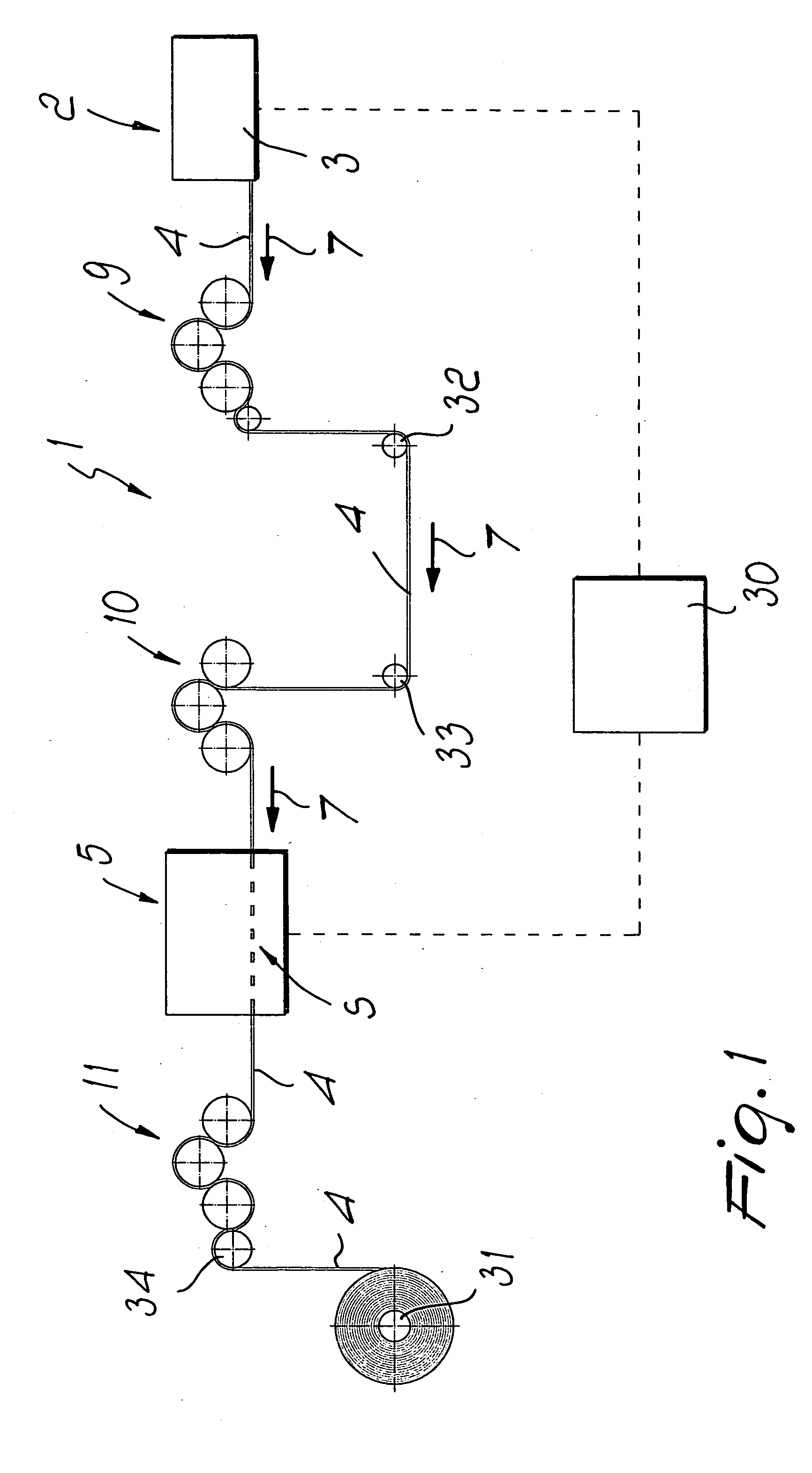

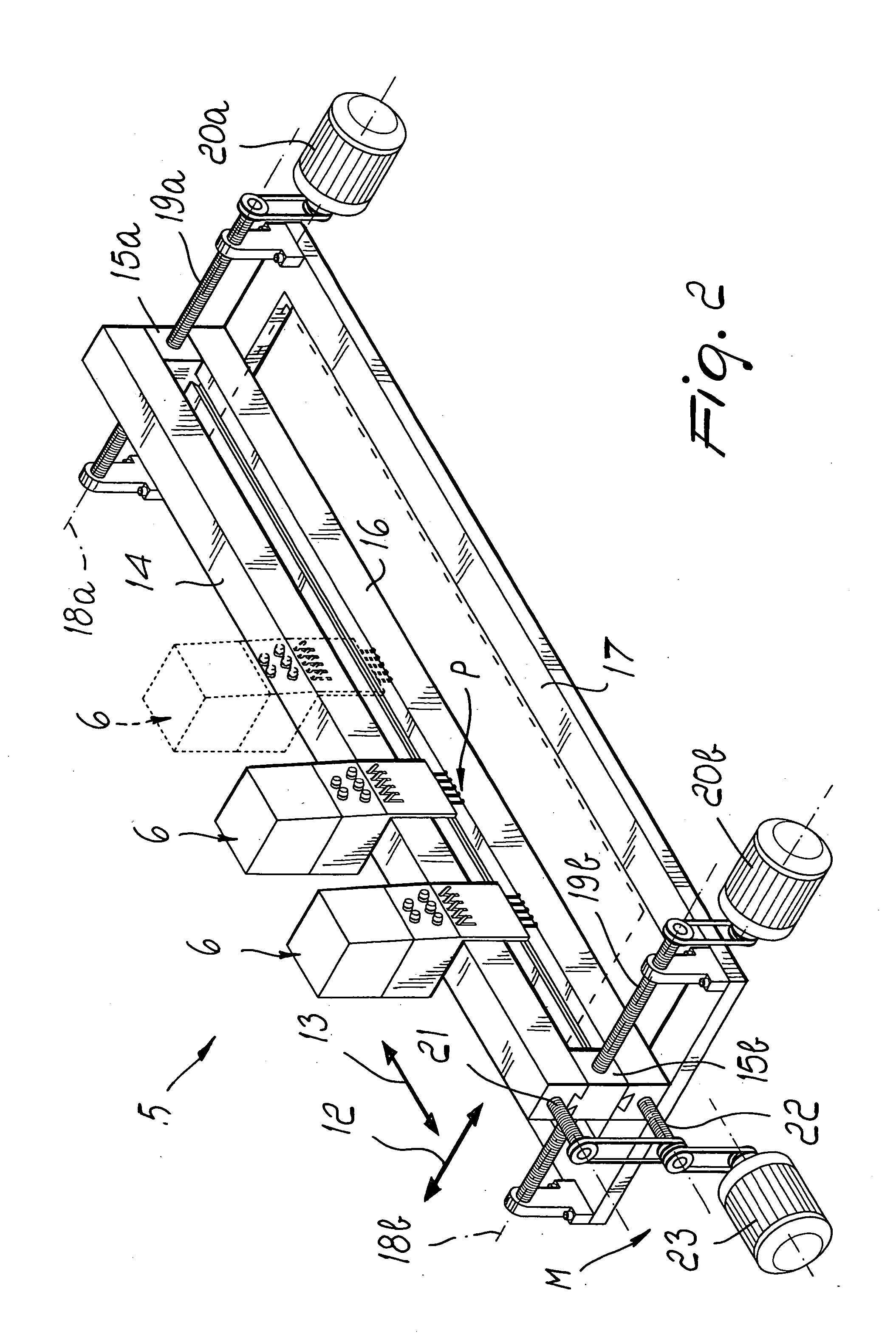

[0020] With reference to the figures, the machine according to the invention, generally designated by the reference numeral 1, comprises a first working station 2, in which there is a loom-weaving machine 3 of a known type, which is capable of producing a sheet of fabric 4, and a second working station 5, in which there is at least one head 6 for embroidering and / or applying decorative elements to the sheet of fabric 4. The machine comprises means for the longitudinal advancement of the sheet of fabric 4 produced in the first working station 2 along an advancement direction 7 through the second working station 5. The advancement means are adapted to support the sheet of fabric 4 on a working surface S that is substantially horizontal at least at the second working station 5, and means for moving the head or heads for embroidering and / or applying decorative elements along a direction that lies transversely to the advancement direction 7 on said working surface are provided.

[0021] Mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com