Embroidering frame moving device of sewing machine

A mobile device and embroidery frame technology, applied in the field of sewing machines, can solve the problems of not being able to sew large CABs, complex structures, and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

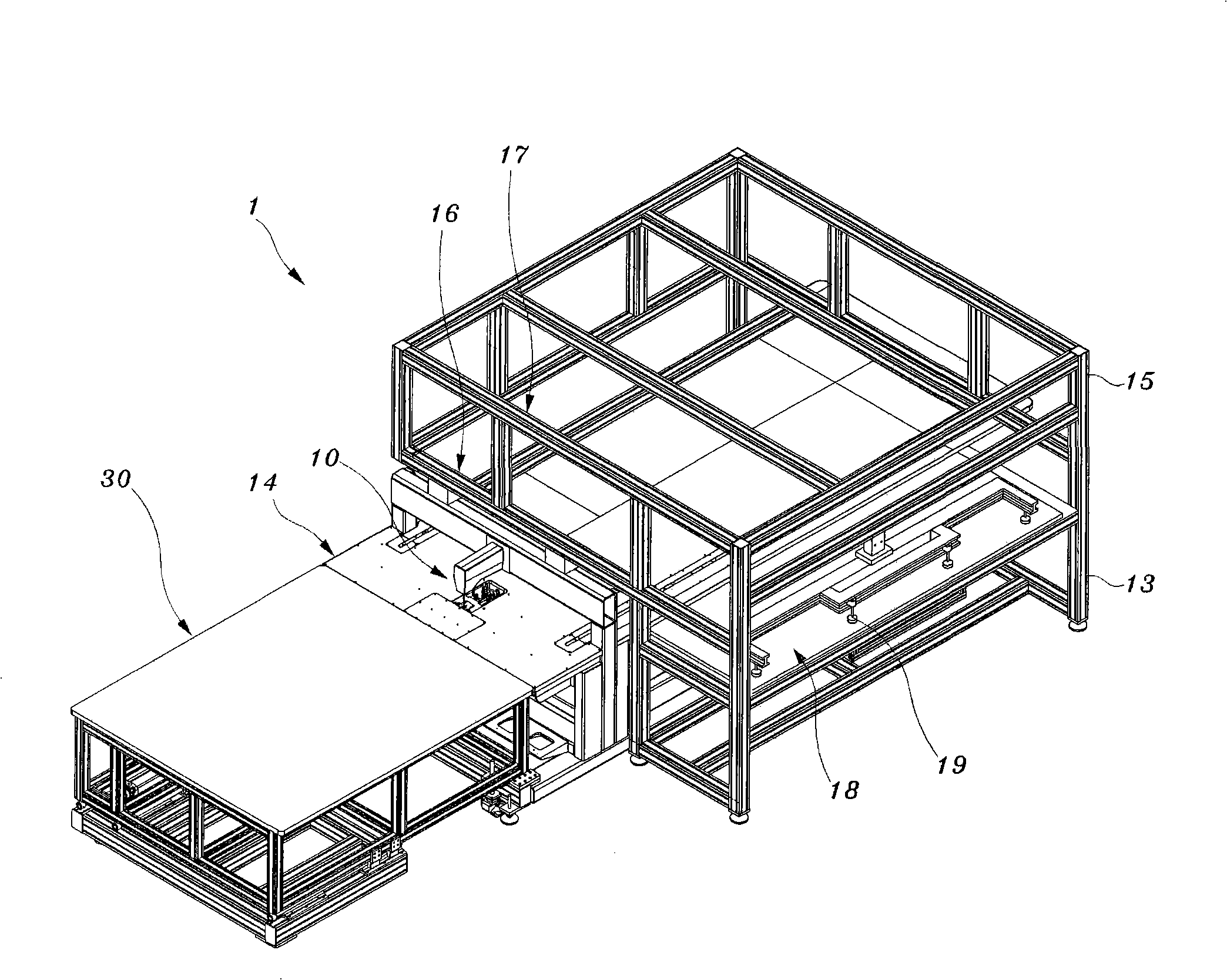

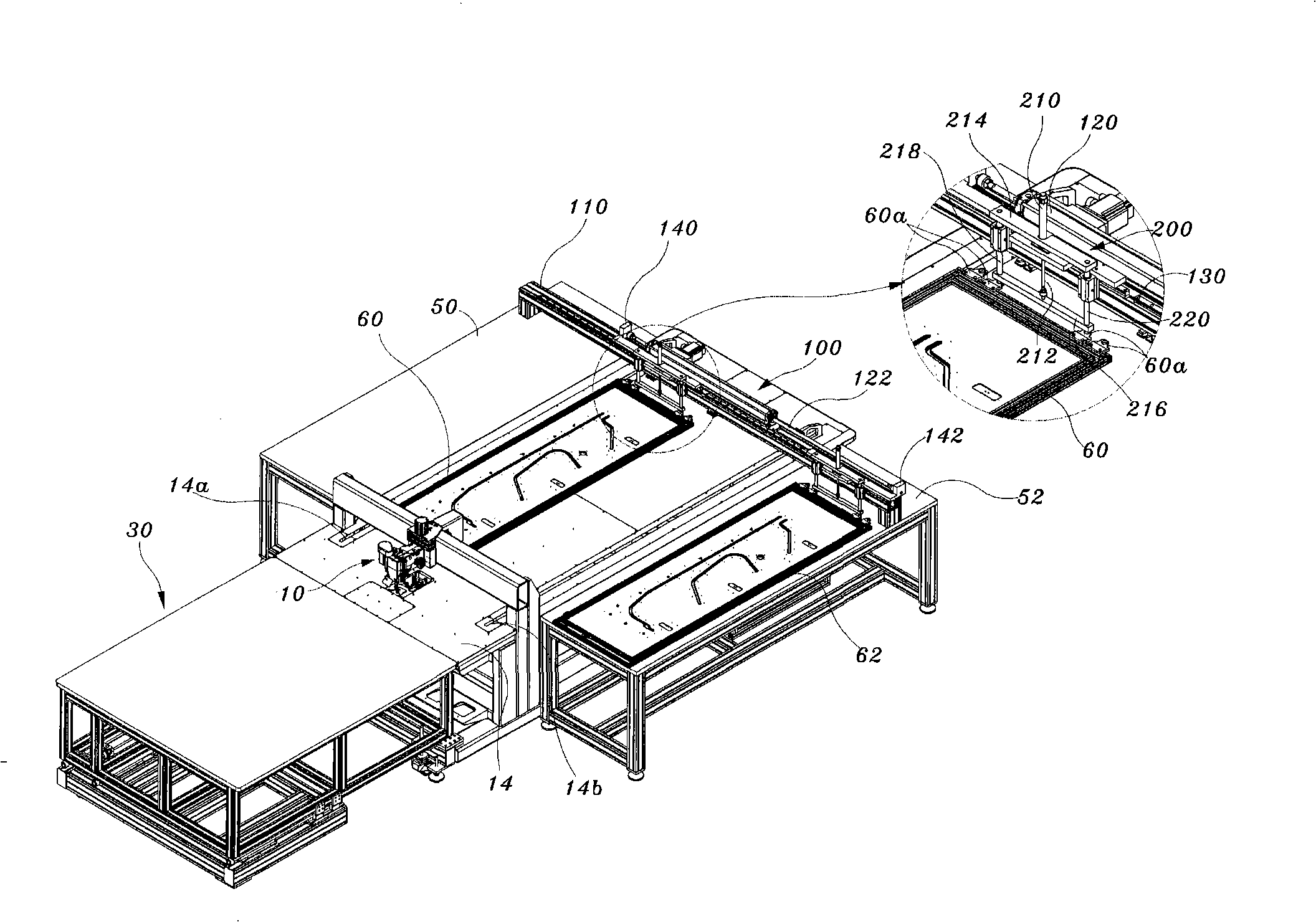

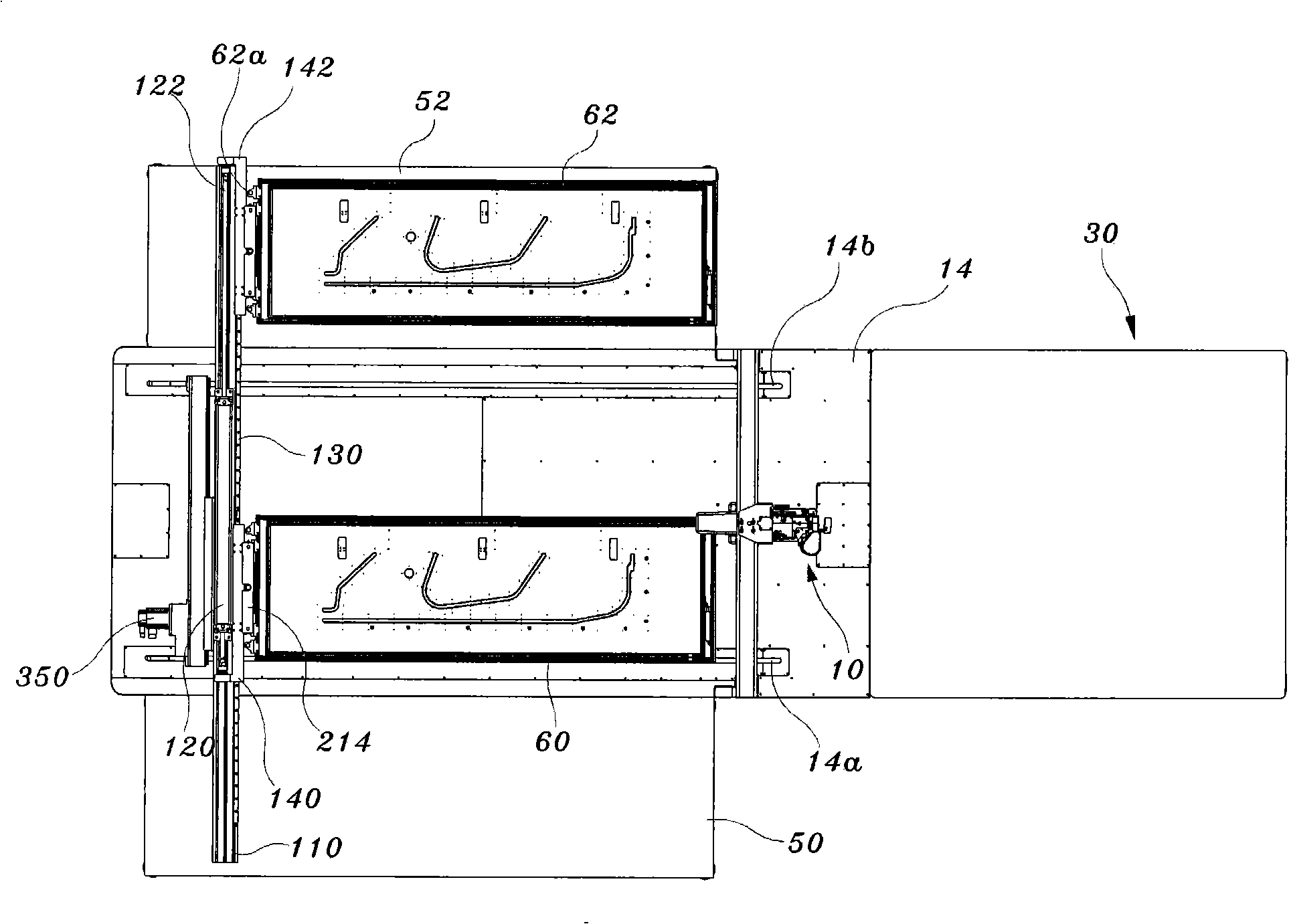

[0030] Hereinafter, the embroidery frame moving device for a sewing machine of the present invention will be more fully described with reference to the accompanying drawings, in which an exemplary embodiment of such a device is shown.

[0031] Figure 2 to Figure 10 An embroidery frame moving device for a sewing machine according to an embodiment of the present invention has been described. see Figure 2 to Figure 10 , the sewing machine embroidery frame moving device of the present invention generally has the following parts: embroidery frame replacement part 100; a pair of embroidery frame installation / disassembly parts 200; embroidery frame lateral (X axis direction) moving part 300; embroidery frame front and back (Y axis direction) a moving part 400; and a control part.

[0032] Such as figure 2 As shown, the embroidery frame replacement unit 100 includes a support member 110 having a substantially U-shaped cross-section. The supporting member 110 is fixedly mounted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com