Grinding wheel arc dresser

An arc dresser and grinding wheel technology, which is applied to abrasive surface adjustment devices, parts of grinding machine tools, metal processing equipment, etc., can solve problems such as low efficiency, reduced precision, and time-consuming adjustment, and achieve the effect of accurate dressing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

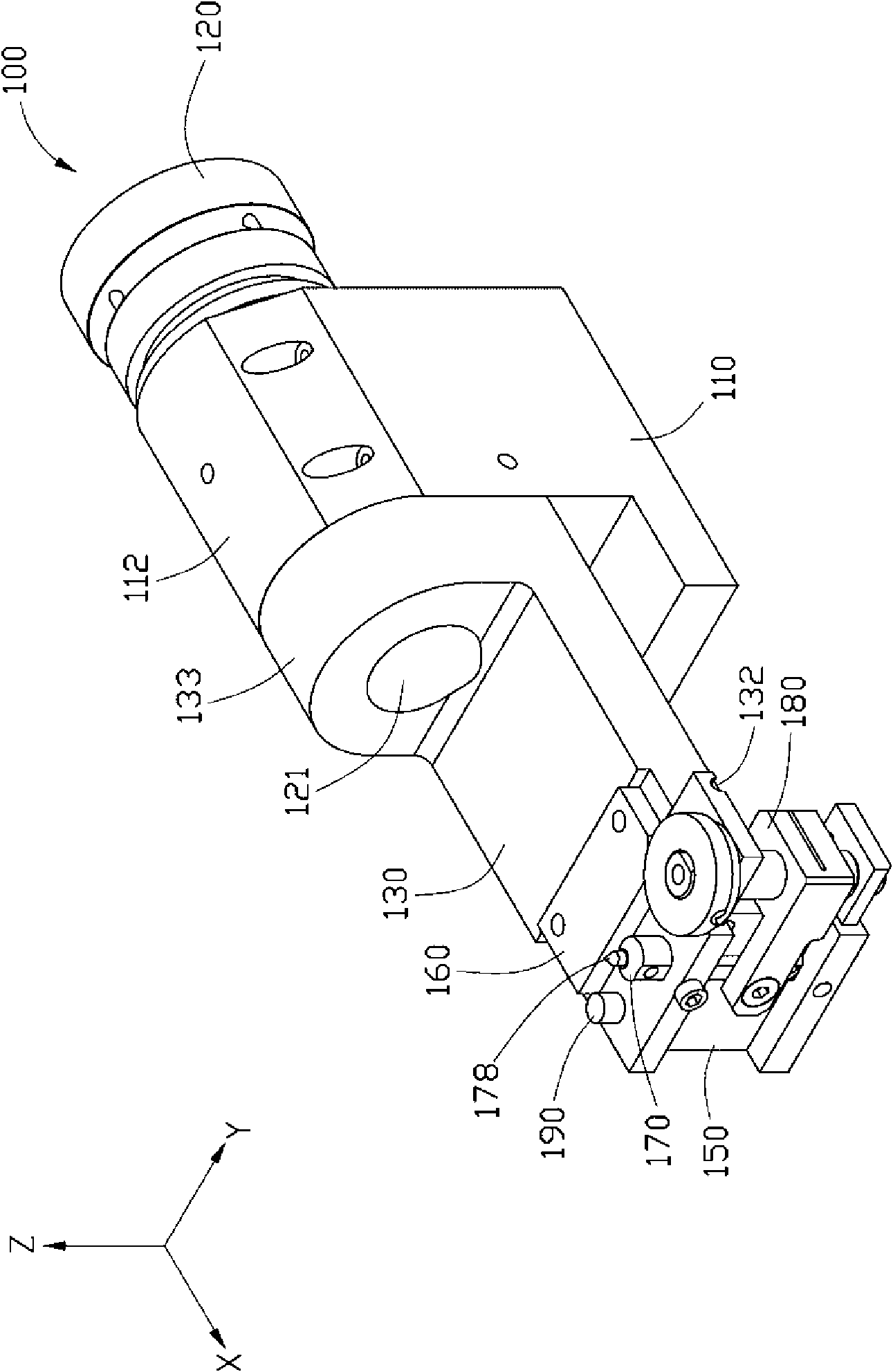

[0013] The grinding wheel arc dresser of the preferred embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

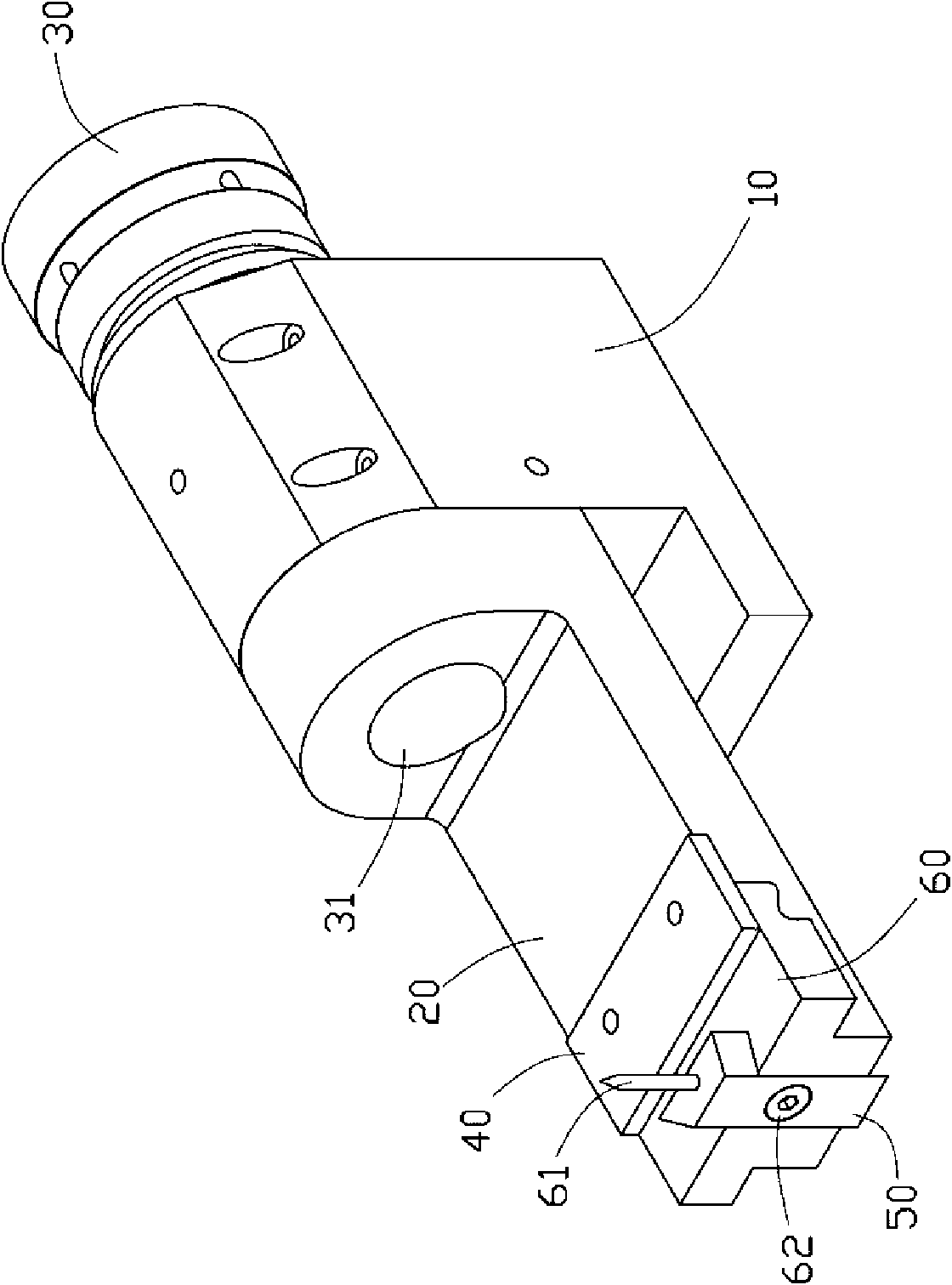

[0014] See image 3 , the grinding wheel dresser 100 described in the first preferred embodiment of the present invention includes a base 110, a rotating body 120, an extension plate 130, a knife seat 150, a splint 160, a dressing knife body 170, an adjustment dressing knife Body 170 position adjustment mechanism 180 and a tool setting rod 190.

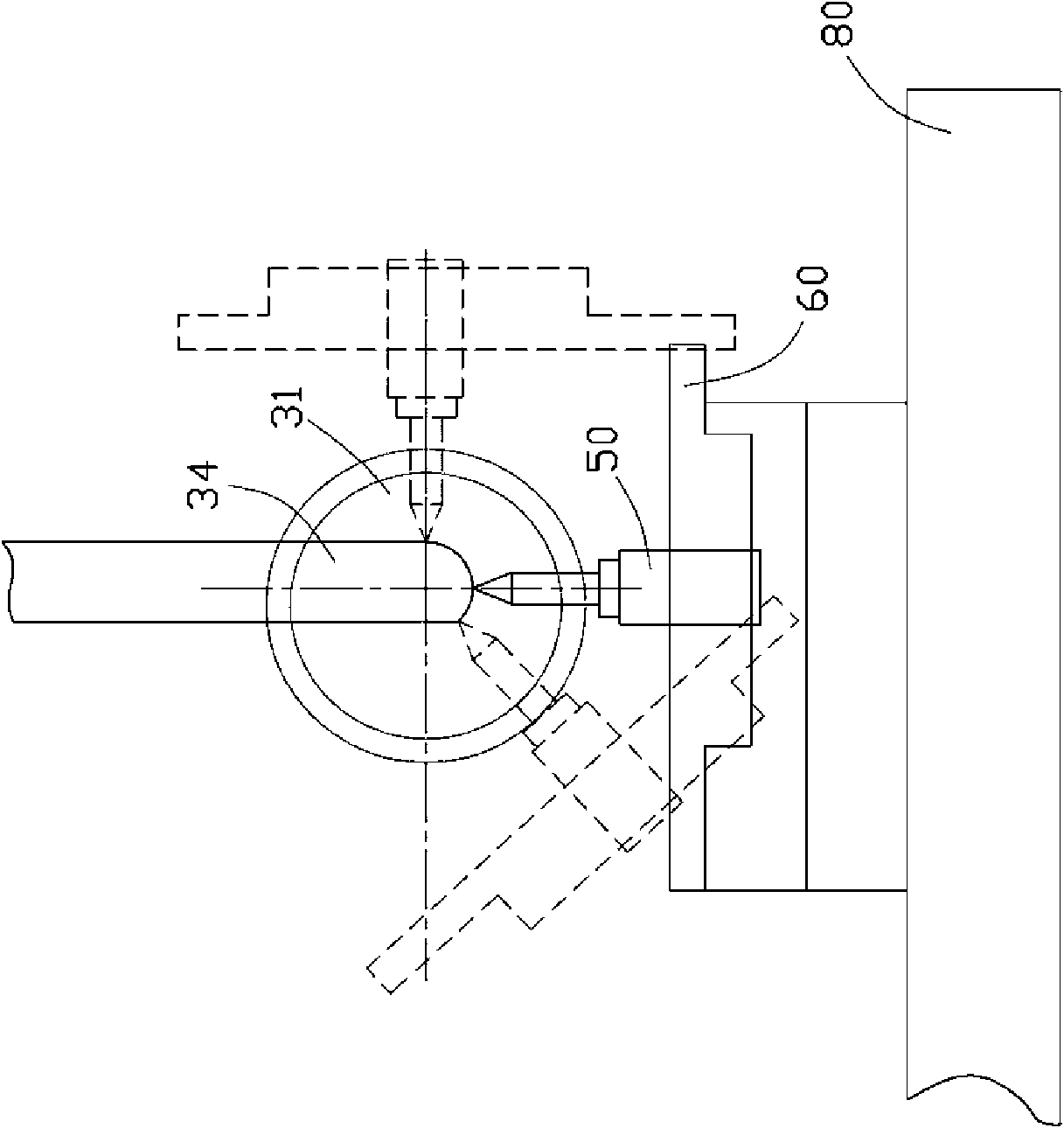

[0015] The top of the base 110 is an arc-shaped top surface 112 . The rotating body 120 and the extension plate 130 are fixedly connected inside the base 110 . The extension plate 130 includes a top surface 133 corresponding to the arc-shaped top surface 112, and the arc-shaped top surfaces 112, 133 are engraved with rotation angle scale lines (not shown). The center of the rotating body 120 is provided with a through hole 121, the through hole 121 runs through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com