Grinding bed dresser

A grinding wheel dresser and grinding machine technology, which is applied to the parts of grinding machine tools, grinding/polishing equipment, abrasive surface adjustment devices, etc., can solve the problems that affect the dressing accuracy and cannot be dressed, and achieve convenient manufacturing, low cost, and easy Achieved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

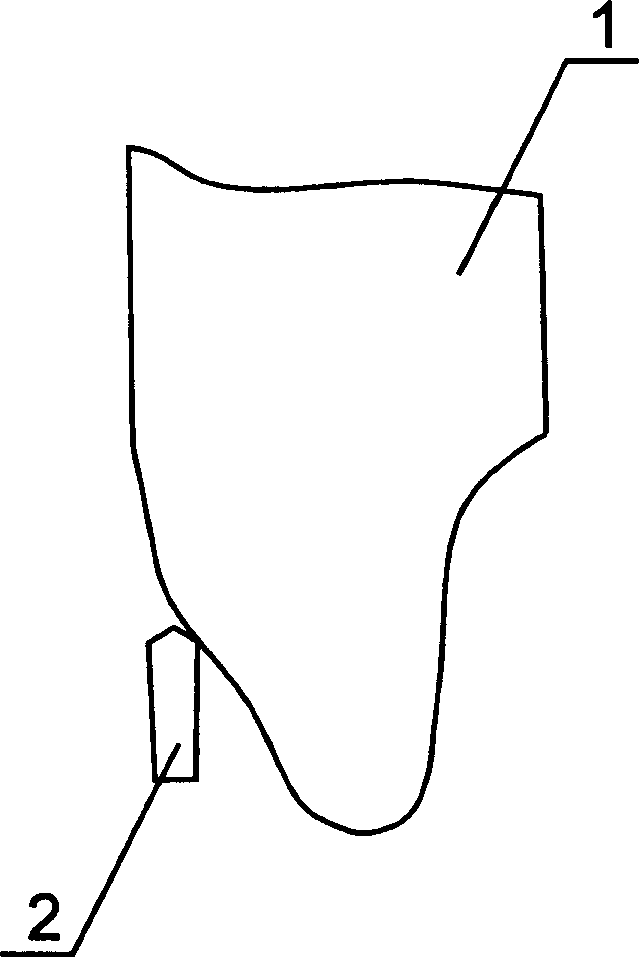

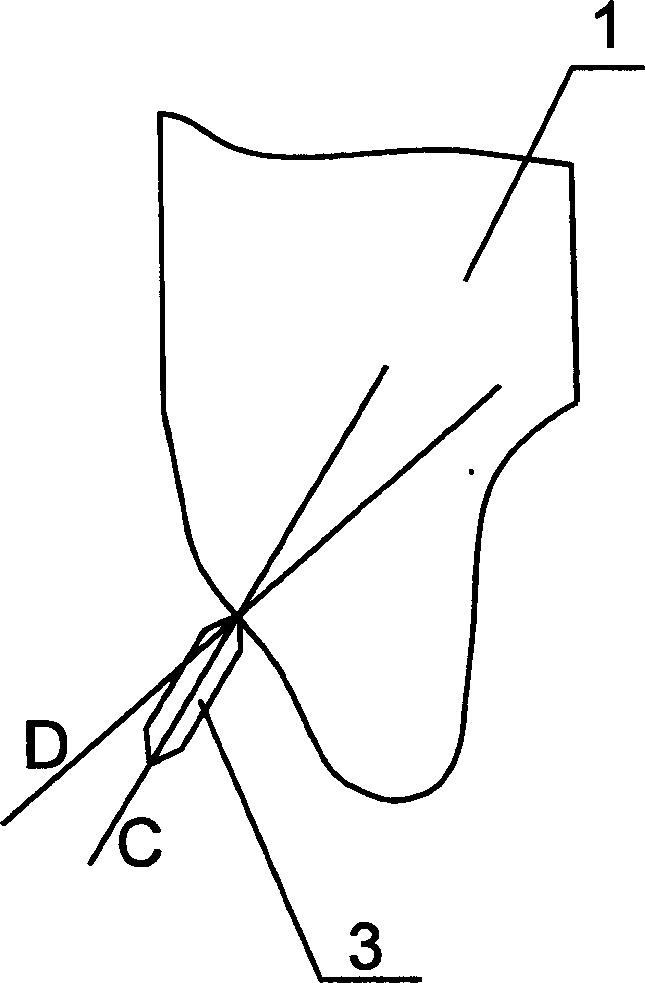

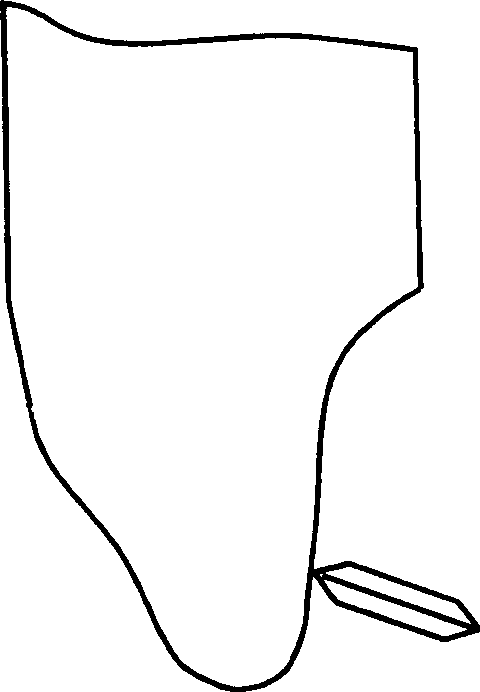

[0018] refer to Figure 5 , 6 , The dresser of the present invention is made of dressing pen 2 or diamond dressing wheel 3 and base 5, and the dresser base 5 is installed on the grinder workbench 4 and can clamp on the workbench of processing workpiece. The grinding machine table 4 can move left and right in the y direction on the grinding machine bed 14, and the grinding wheel base 15 can move forward and backward in the x direction on the grinding machine bed. A turntable 6 is provided above the dresser base 5, and the front end of the base is provided with a groove parallel to the plane of the grinder workbench near the grinding wheel end. The groove is provided with a worm wheel 7 and a worm screw 8, and the worm wheel is driven by a motor A9. The worm 8 drives the worm wheel to rotate, and the rotating shaft 13 of the worm wheel is the rotating shaft of the turntable 6. In this way, the turntable is driven to rotate by the motor A, and the rotation angle of the motor A i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com