Composite cutter service life monitoring system and method based on machine vision

A service life, machine vision technology, applied in the direction of manufacturing tools, measuring/indicating equipment, metal processing machinery parts, etc., can solve the problems of reducing the working efficiency of the device, increasing the error of monitoring work, and precise detection of wear and tear, so as to increase the practicality , Improve work efficiency and increase recognition efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

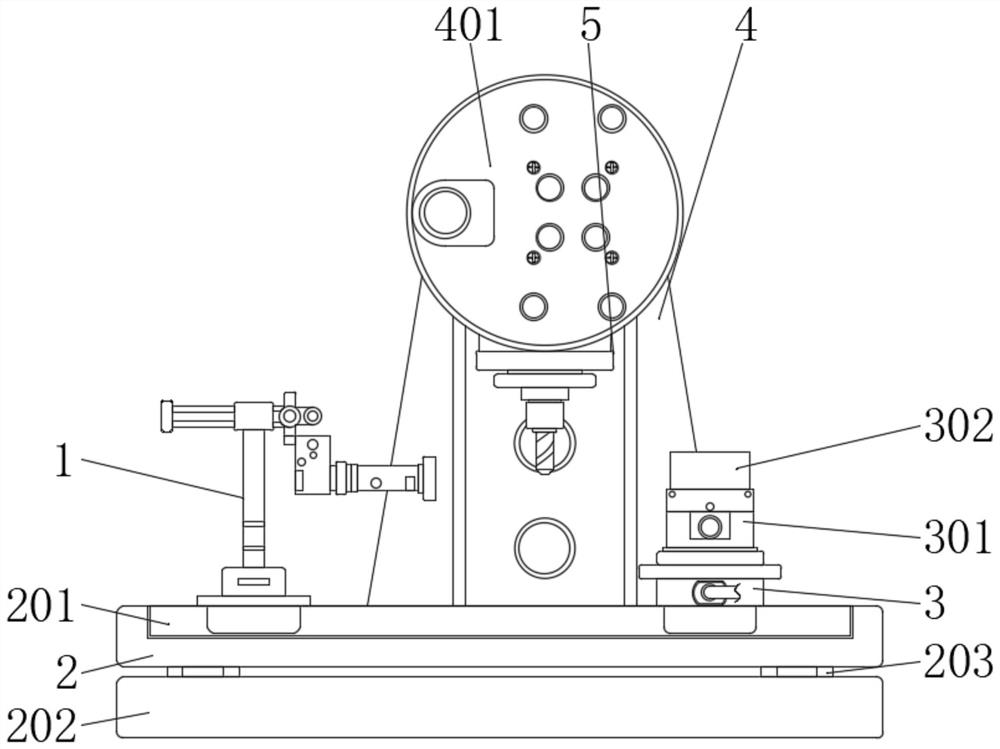

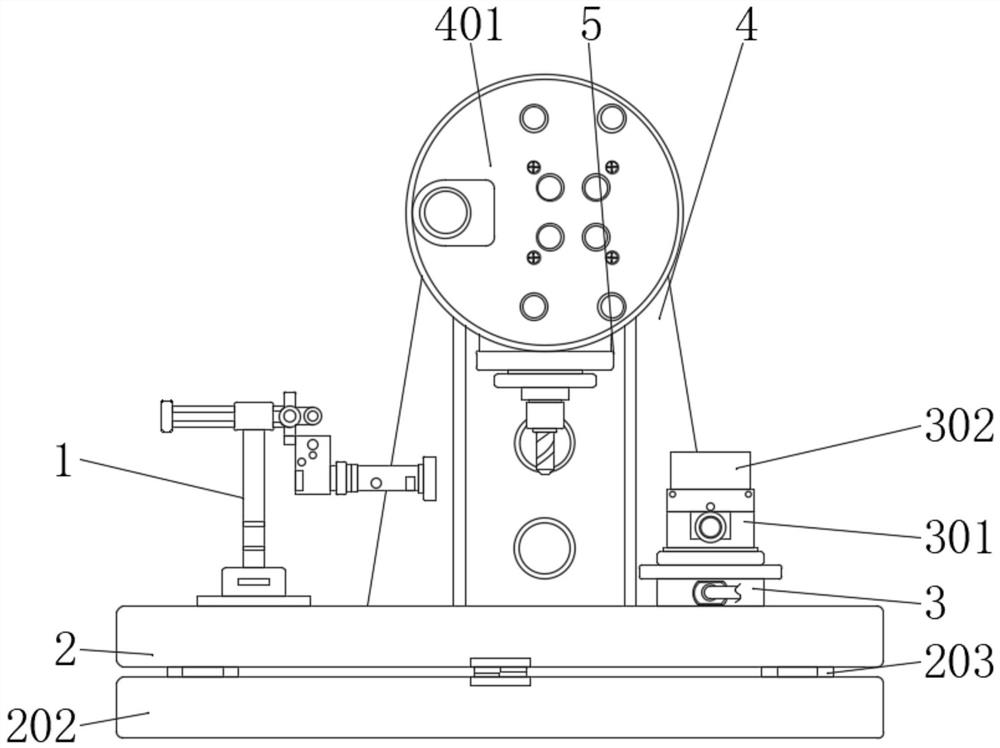

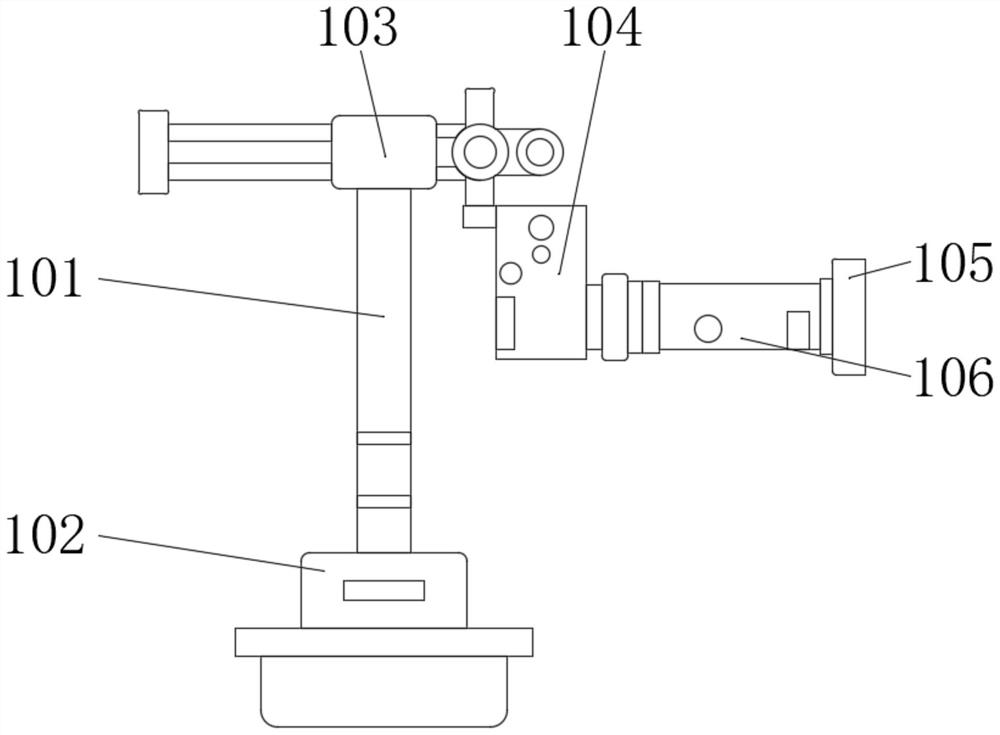

[0040] like Figure 1-5As shown, a machine vision-based composite tool service life monitoring system and method proposed by the present invention includes a monitoring component 1, a chute seat 2, a sliding seat 3 and a tool assembly 5, and a guide is provided inside the chute seat 2 Slot 201, a support seat 4 is installed on one side of the chute seat 2, a drive module 401 is installed on the top of the support seat 4, a tool assembly 5 is installed on the bottom side of the drive module 401, and a mounting plate is installed in the tool assembly 5 501, a knife seat 503 is installed on the bottom of the mounting plate 501, a sliding seat 3 is installed on the top side of the chute seat 2, and a monitoring component 1 is installed on the side of the top of the sliding groove seat 2 away from the sliding seat 3, and the monitoring component 1 A base 102 is installed, a rotating shaft 101 is installed on one side of the base 102 , a fixing base 103 is installed on the top of th...

Embodiment 2

[0053] like Figure 1-5 As shown in the figure, a system and method for monitoring the service life of a composite tool based on machine vision proposed by the present invention, compared with the first embodiment, the present embodiment further includes: a telecentric lens 106 is installed on one side of the camera 104, and the telecentric lens 106 is installed on one side. A ring light 105 is installed on one side of the central lens 106, a mounting shaft 203 is installed on both sides of the bottom of the sliding slot seat 2, and a mounting plate 202 is installed at the bottom of the mounting shaft 203, and a fixing plate 301 is installed on the top of the sliding seat 3, And a workpiece 302 is installed on the top of the fixing plate 301 , a motor is installed inside the drive module 401 , and the output end of the motor extends out of the bottom of the drive module 401 , and a tool bar 502 is installed at the bottom of the tool holder 503 , and the tool bar is A milling c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com