Automatic grinding machine for cutting edge of surgical knife blade

A technology of surgical blades and grinding machines, which is applied to other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of high quality, large-scale production, complicated grinding of surgical blade edges, and affecting the production efficiency of surgical blades, etc. Problems, to achieve the effect of improving production efficiency and processing quality, high practical value, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] Embodiment: A kind of surgical blade edge automatic grinding machine

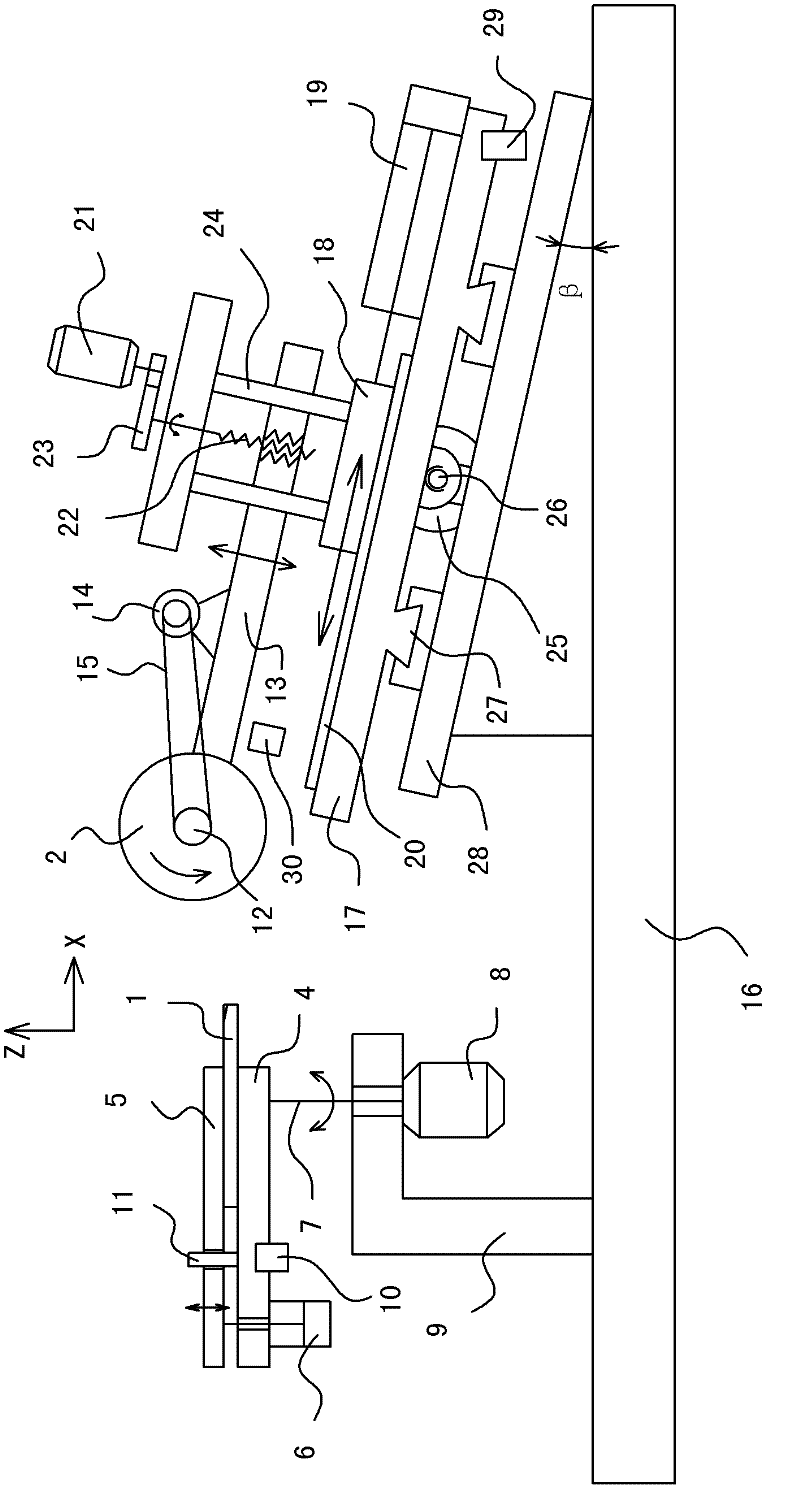

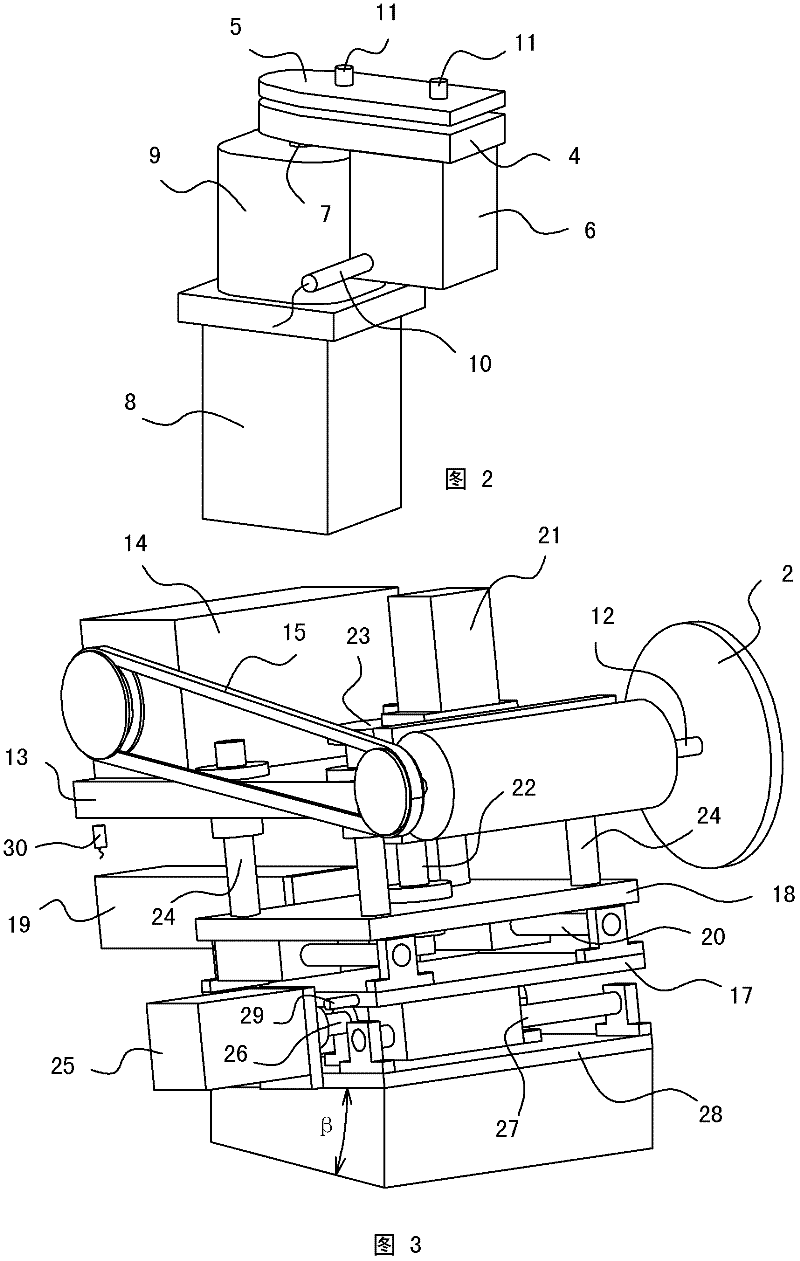

[0040] like figure 1 As shown, the automatic grinding machine includes a rotary tool holder mechanism (see figure 1 the left half of the), a grinding head mechanism (see figure 1 The right half of), a base 16 and the electrical control part.

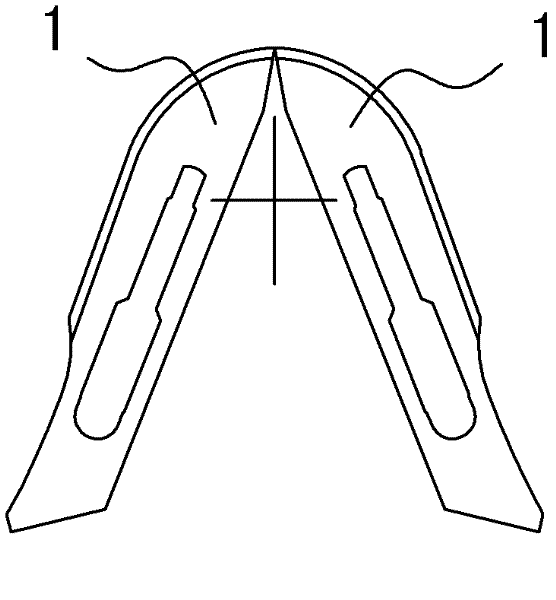

[0041] like figure 1 and figure 2 As shown, the rotary knife seat mechanism has a knife seat body 4 for positioning the surgical blade 1, and the knife seat body 4 is provided with a pressing plate 5 for pressing the surgical blade 1, and the pressing plate 5 and the knife seat body 4 are arranged vertically. The sliding connection is formed by the guide pin 11 in the direction of the straight Z axis. A pressing device is installed on the tool holder body 4, the pressing device is a pressing cylinder 6, the piston rod of the pressing cylinder 6 is connected with the pressing plate 5 as the action end of the pressing device, under the action of the pressing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com