Multi-station circular-disc type novel numerical control automobile hub polishing machine

A technology for automobile wheels and polishing machines, which is applied to surface polishing machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc. It can solve the problems of reduced production efficiency, high labor intensity of workers, and inability to adjust the rotation angle. Achieve the effects of reducing equipment energy consumption and production costs, high-quality and high-efficiency polishing, and improving production efficiency and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

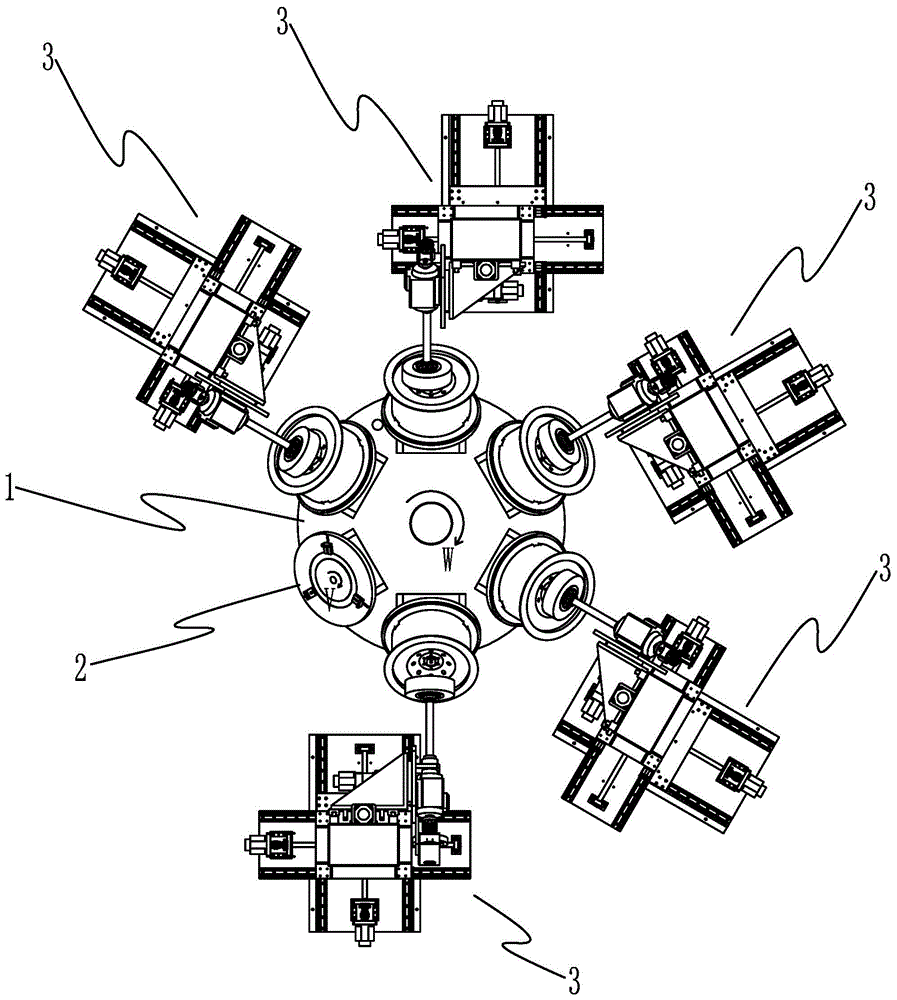

[0029] like Figures 1 to 8 As shown, the multi-station disc type new type automobile hub CNC polishing machine of the present invention adopts a six-station polishing machine.

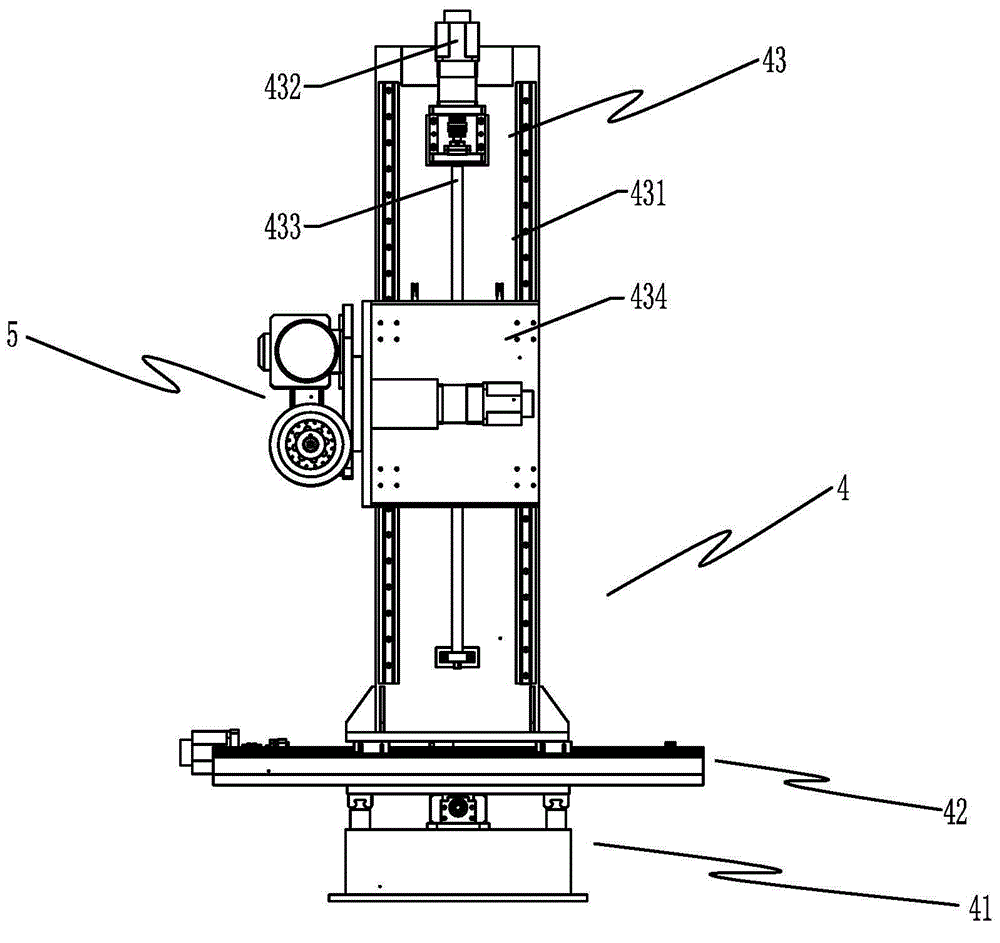

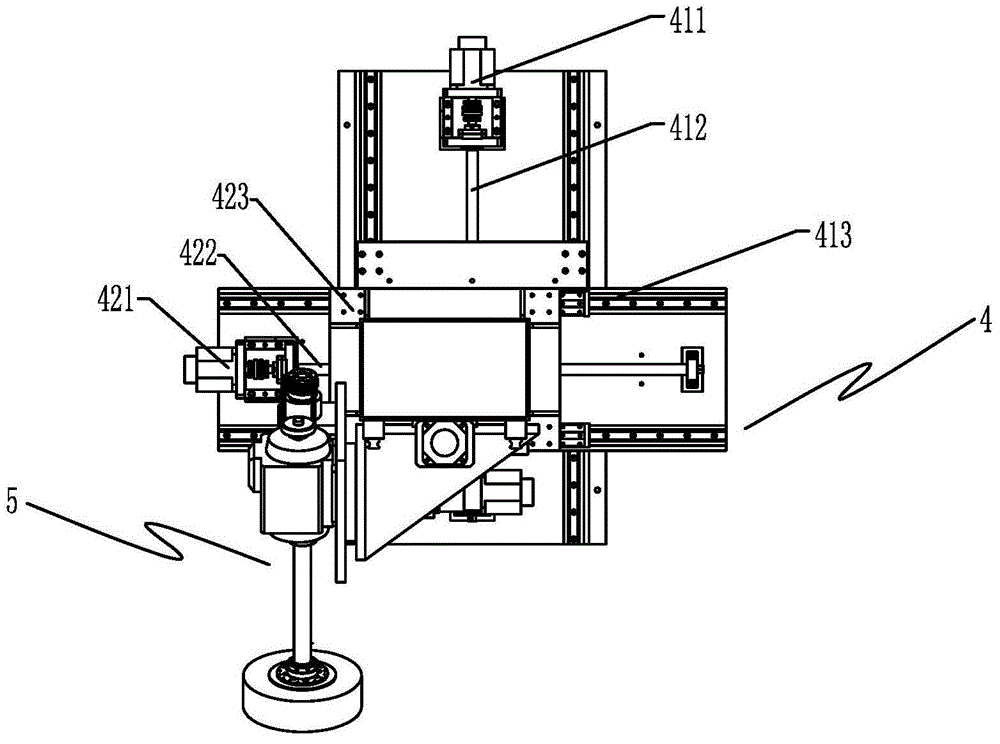

[0030]The above-mentioned six-station disc-type new-type automobile hub CNC polishing machine includes a central revolving disc assembly 1, and a six-station auto-rotating hub clamp assembly 2 is evenly arranged at equal angles along the circumferential direction on the revolving disc assembly 1, which revolves around the The disc assembly 1 and the self-rotating hub clamp assembly 2 corresponding to each station are arranged with five-station asynchronous polishing wheel assembly 3 and one-station loading and unloading station, wherein the polishing wheel assembly 3 of each station includes three The direction displacement part 4 and the polishing wheel head part 5 which is arranged on the three-way displacement part and deflects a predetermined angle along the horizontal transverse axis, the three-w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com