Polishing clamping device for watch covers

A technology of clamping device and watch cover, which is applied in the direction of grinding/polishing equipment, parts of grinding machine tools, and machine tools suitable for grinding workpiece planes, etc., which can solve the problems of high cost, glass surface scratches, and long processing time And other problems, to achieve the effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

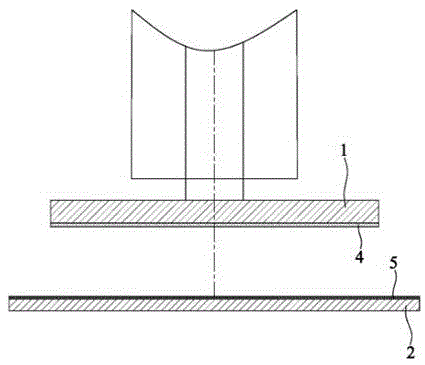

[0022] Such as figure 1 As shown, the polishing clamping device of the watch cover of the present invention fixes a layer of pickle cloth 4 used as the polishing wheel of the upper grinding disc 2 on the upper grinding disc 1 of the glass polishing machine. (Pickup cloth is another name for scouring pads. Industrial scouring pads are usually used by hand or machines. They are professional, efficient, and easy to clean, which greatly saves the complexity of surface treatment.)

[0023] Pickle melon cloth 4 is fixed on the upper millstone 1 by stainless steel wire. The size of the pickle cloth 4 is the same as that of the upper millstone 1, and the use effect is good when the pickle cloth 4 completely covers the upper millstone 1.

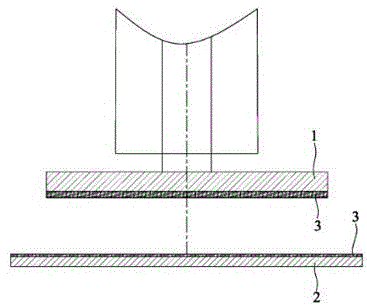

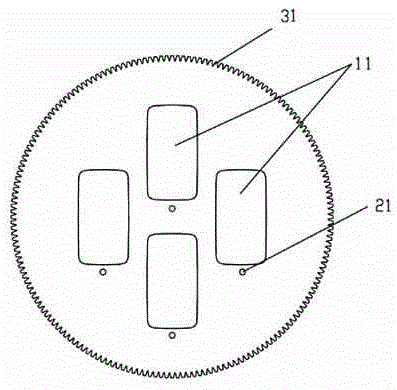

[0024] Such as image 3 , 4 As shown, the lower grinding disc is provided with a positioning plate 5 made of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com