Multi-station disc type CNC polishing machine for new basin workpieces

A disc-type, multi-station technology, which is applied to surface polishing machine tools, grinding/polishing equipment, manufacturing tools, etc., can solve the problems of high labor intensity, expensive equipment, and inability to polish workpieces of different sizes. , to achieve high-quality and high-efficiency polishing, reduce equipment energy consumption and production costs, and improve production efficiency and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

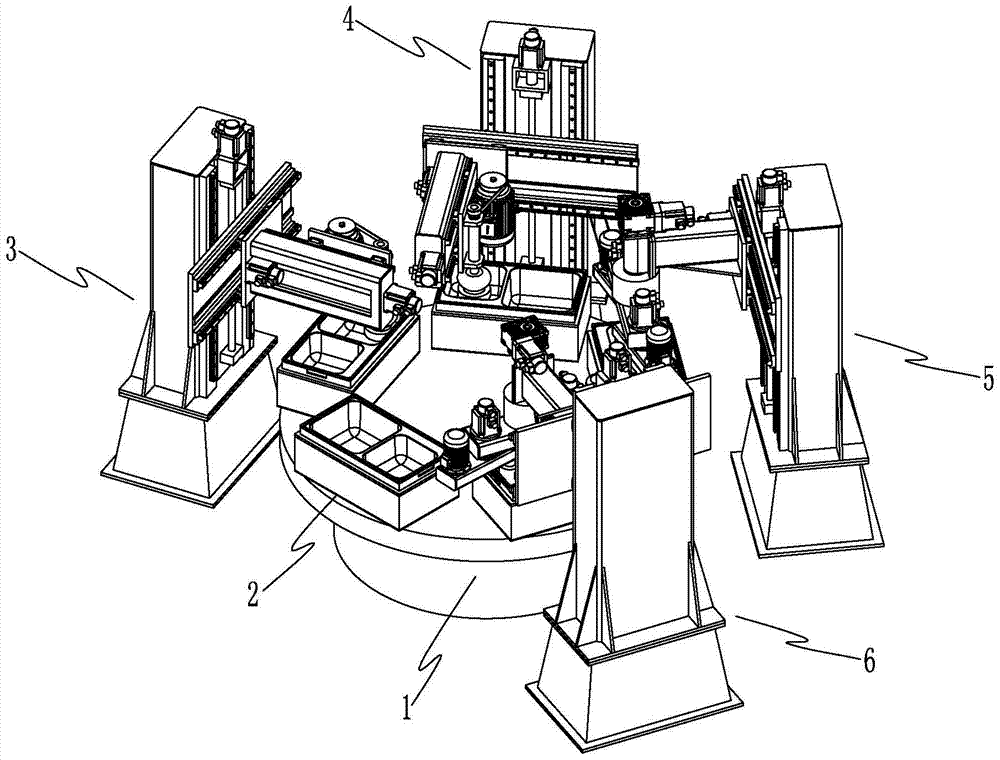

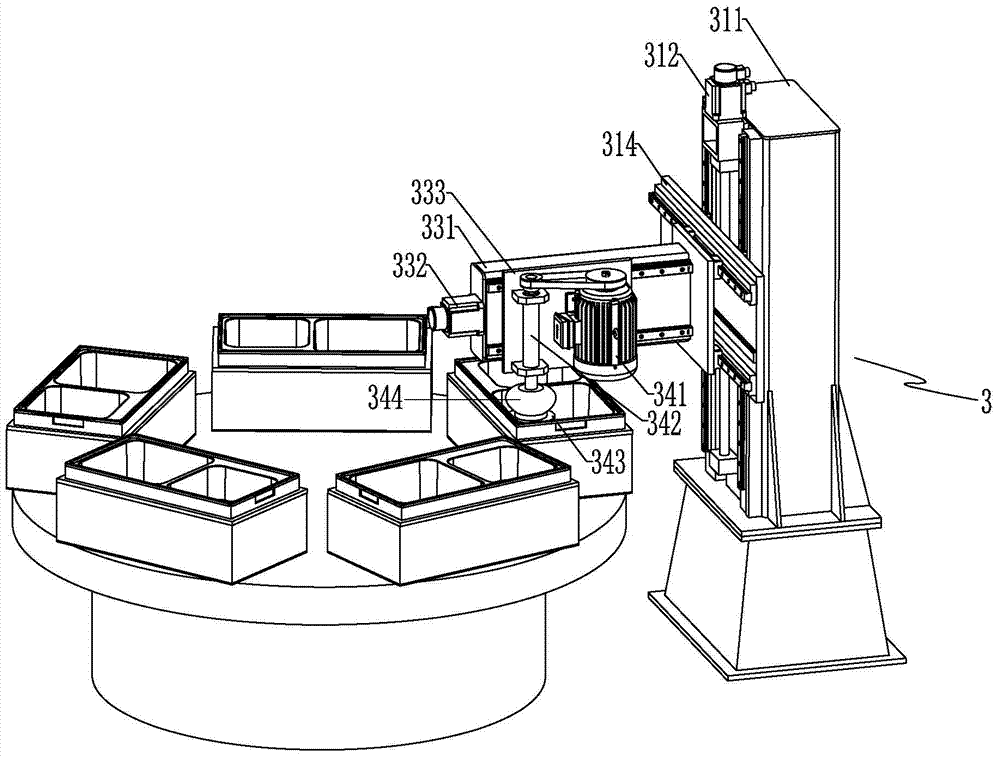

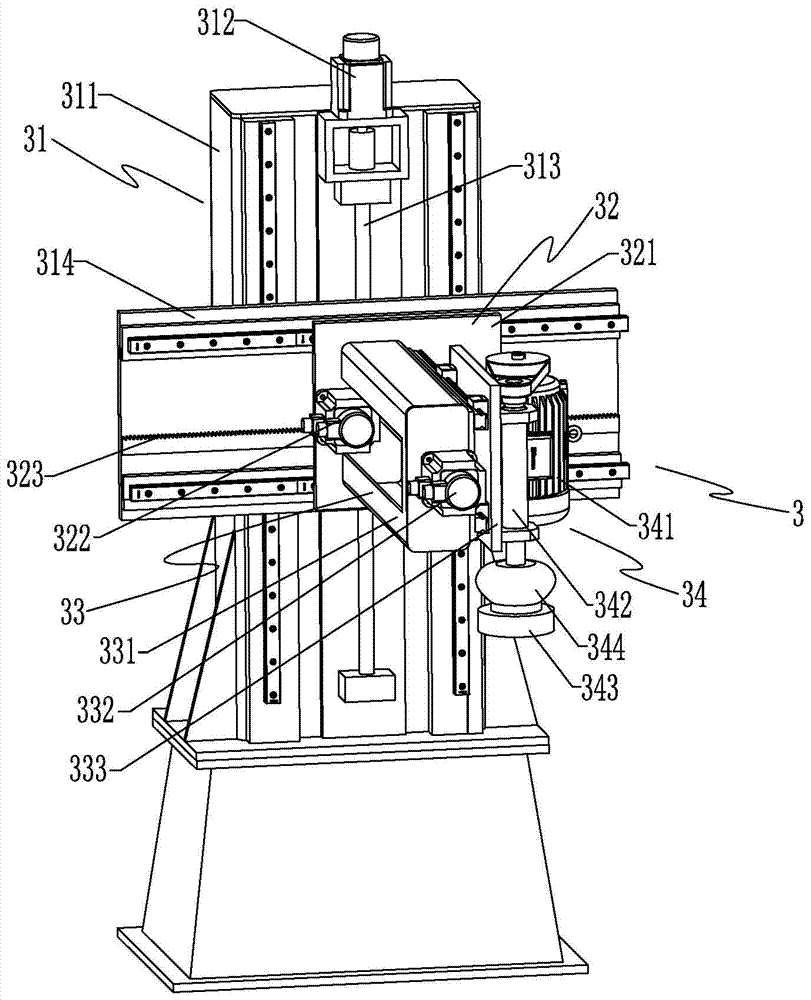

[0030] Such as Figures 1 to 6As shown, the multi-station disc type new-type CNC polishing machine for basin workpieces described in the present invention adopts a five-station polishing machine. The five-station polishing machine includes a turntable assembly 1 arranged in the middle, and the top of the turntable assembly 1 There are five-station pneumatic suction cup assemblies evenly arranged at equal angles along the circumferential direction, a loading and unloading station 2 is arranged on the periphery of the turntable assembly 1 corresponding to one of the above-mentioned pneumatic suction cup components, and the periphery of the turntable assembly 1 corresponds to each of the other pneumatic suction cup components mentioned above Arrange one station of large-diameter single polishing wheel assembly 3, one station of small-diameter single polishing wheel assembly 4, one station of large-diameter double polishing wheel assembly 5, and one station of small-diameter double...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com