Novel six-station disc-type numerical control cloth wheel buffing machine

A cloth wheel polishing, disc-type technology, applied in surface polishing machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc. problems, to improve production efficiency and economic benefits, reduce equipment energy consumption and production costs, high-quality and high-efficiency polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

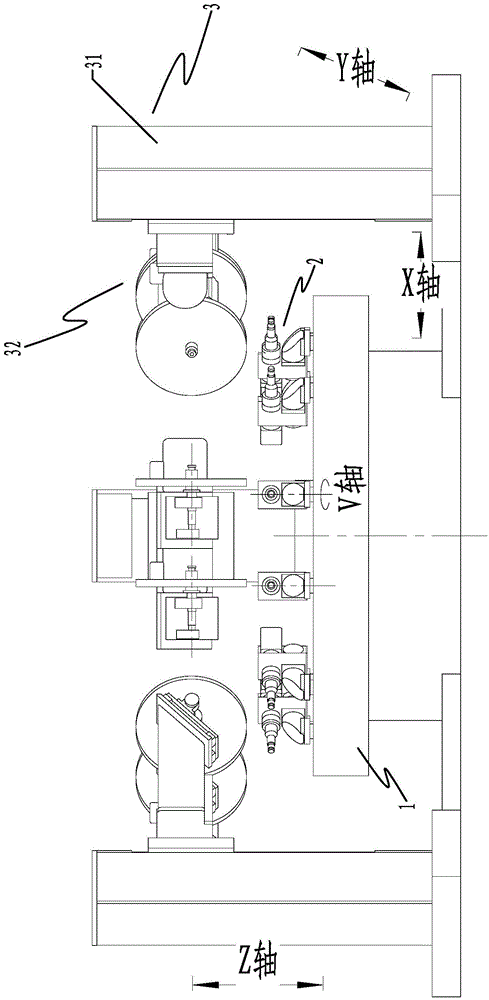

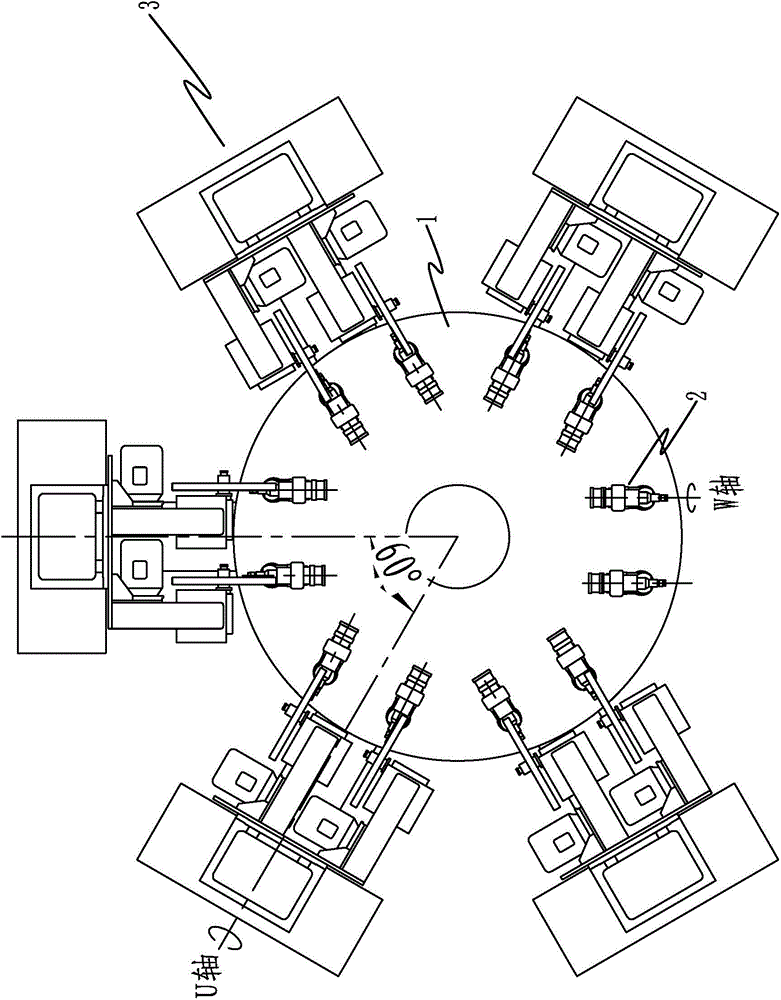

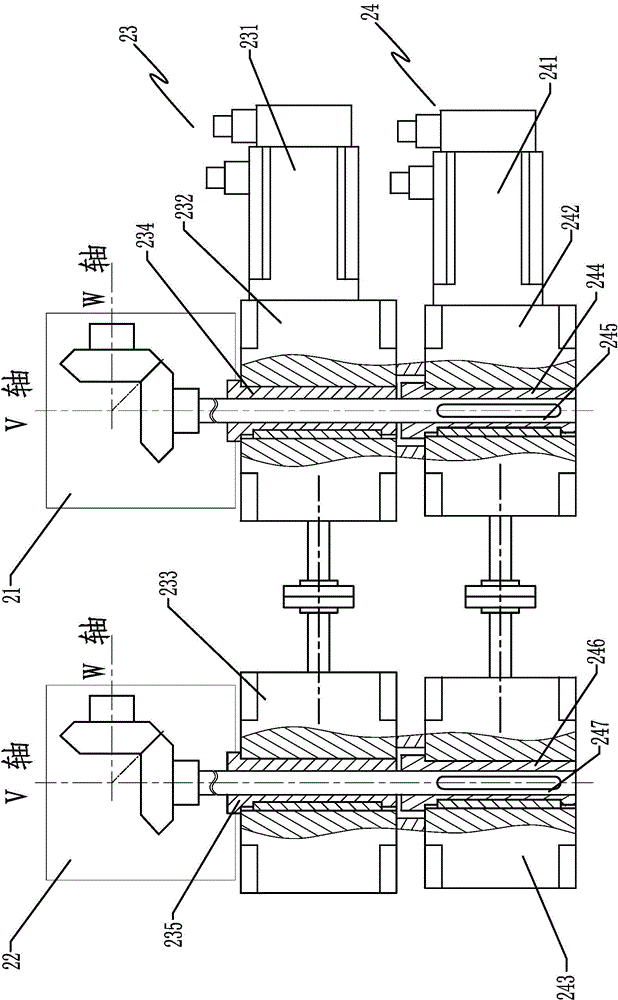

[0028] Such as Figures 1 to 6 As shown, the six-station disc-type new CNC cloth wheel polishing machine of the present invention includes a base and a rotating disc arranged in the middle of the base. The base is evenly arranged with five-station dual-panels around the rotating disc. The polishing wheel assembly and the one-station loading and unloading station, the rotating disk corresponds to the above-mentioned five-station double polishing wheel assembly and the one-station loading and unloading station, and the six-station double workpiece fixture assembly is evenly arranged at an equal angle Each of the above-mentioned double polishing wheel assemblies includes a movable column and a double polishing wheel structure arranged on the column corresponding to the above-mentioned double workpiece fixture assembly, and the above-mentioned double workpiece fixture assembly of each station includes two linkage-fit workpiece holders head.

[0029] Wherein: each of the above-men...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com