High-precision cylinder sleeve inner wall enclosed special-shaped curve groove processing method

A processing method and technology of cylindrical sleeves, which are applied in the processing field of closed special-shaped curved grooves on the inner wall of high-precision cylindrical sleeves, can solve the problems of poor processing accuracy and low processing efficiency, and achieve improved processing accuracy and efficiency, high precision, and accurate coordinates Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

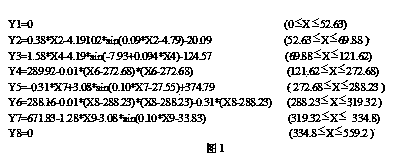

[0059] exist figure 1 In , the six-segment curve equation is to convert the given radian equation into the perimeter to realize the simulation of the equidistance line.

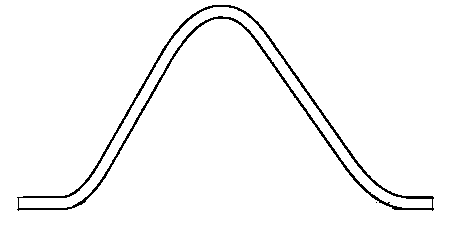

[0060] exist figure 2 , the expanded view of a closed curved trough.

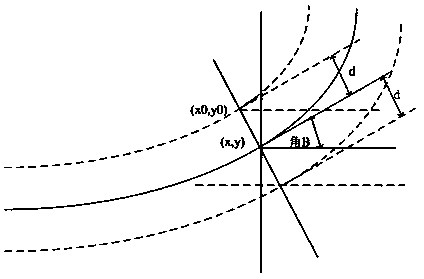

[0061] exist image 3 where are the node coordinates for calculating the equidistance line.

[0062] exist Figure 4 In the trajectory path, the adaptive screening method is adopted to determine the step size:

[0063] (1) Take a series of dense points on the tool path, where the x coordinate is an arithmetic sequence, Figure 4 Midpoint P 1 ,P 2 ,P 3 ,P 4 、…P s

[0064] (2) Determine the starting point of the first cutting step length as p 0 , the end point is p s

[0065] (3) Calculate the coordinates of the pi point (x pi ,y pi ),

[0066] t 0 =t*t 0 ;

[0067] D. pi =sqrt((y ps -y p0 )*( y ps -y p0 )+(x ps -x p0 ) / t 0 *( x ps - x p0 ) / t 0 );

[0068] x =(x ps –x p0 ) / (t*t 0 )+x p0 ;

[0069] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com