Tension rod type hanging and height adjusting mechanism

A height-adjusting, pull-rod-type technology, applied in the field of new adjustment mechanisms, can solve problems affecting the speed and stability of rail vehicles, power consumption, and affecting linear motors, etc., to achieve shortened maintenance time, excellent dynamic performance, and reasonable suspension systems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

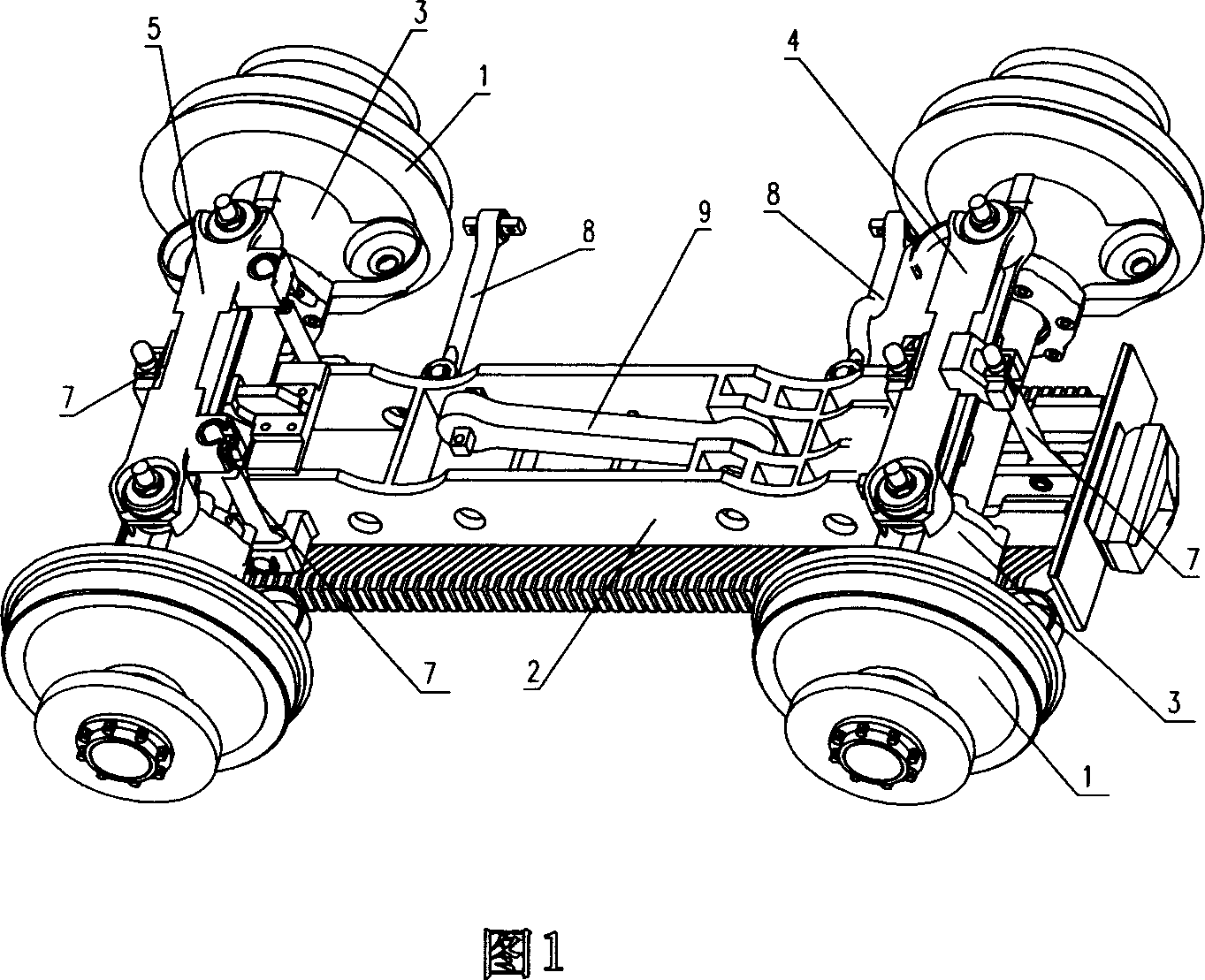

[0058] Embodiment 1, as shown in Figures 1 to 7, the tie rod type suspension and height adjustment mechanism of the present invention is provided with a transverse support beam 4 and a transverse support beam 5 on the two axle boxes 3 of the front and rear wheel sets 1, respectively. .

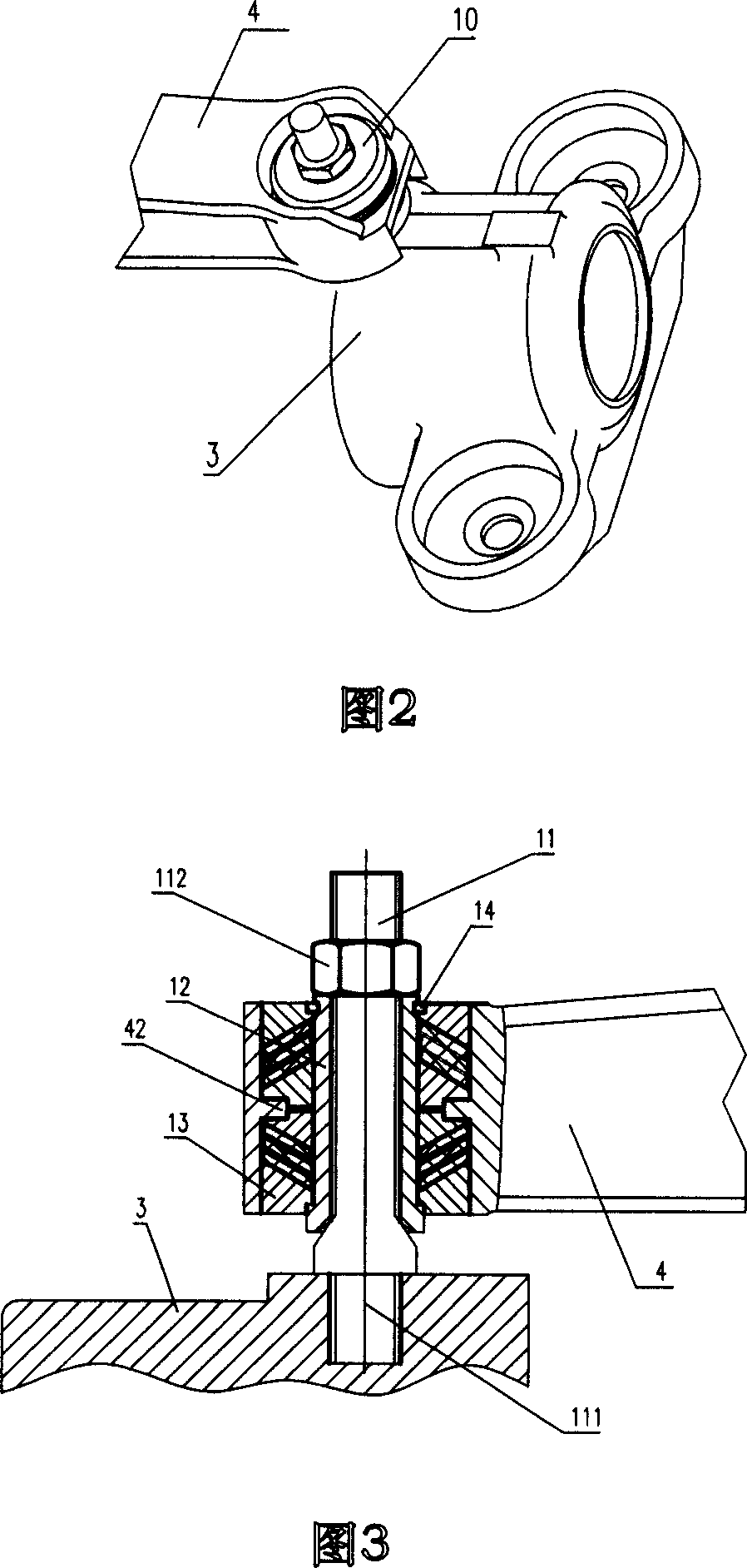

[0059] The end of the support beam is connected and supported on the axle box by the connecting mechanism 10.

[0060] In this embodiment, each bogie adopting a linear traction motor is equipped with a linear motor 2. Each linear motor 2 is suspended and connected by a lateral support beam 4 and a lateral support beam 5, and five vertical tie rods 7, so that the linear motor 2 is installed at the center of the axle.

[0061] As shown in FIG. 1, two vertical tie rods 7 symmetrically hang the inner and outer central parts of the lateral support beam 4.

[0062] The three vertical tie rods 7 hang the inside and outside of the lateral support beam 5 in a "pin" shape.

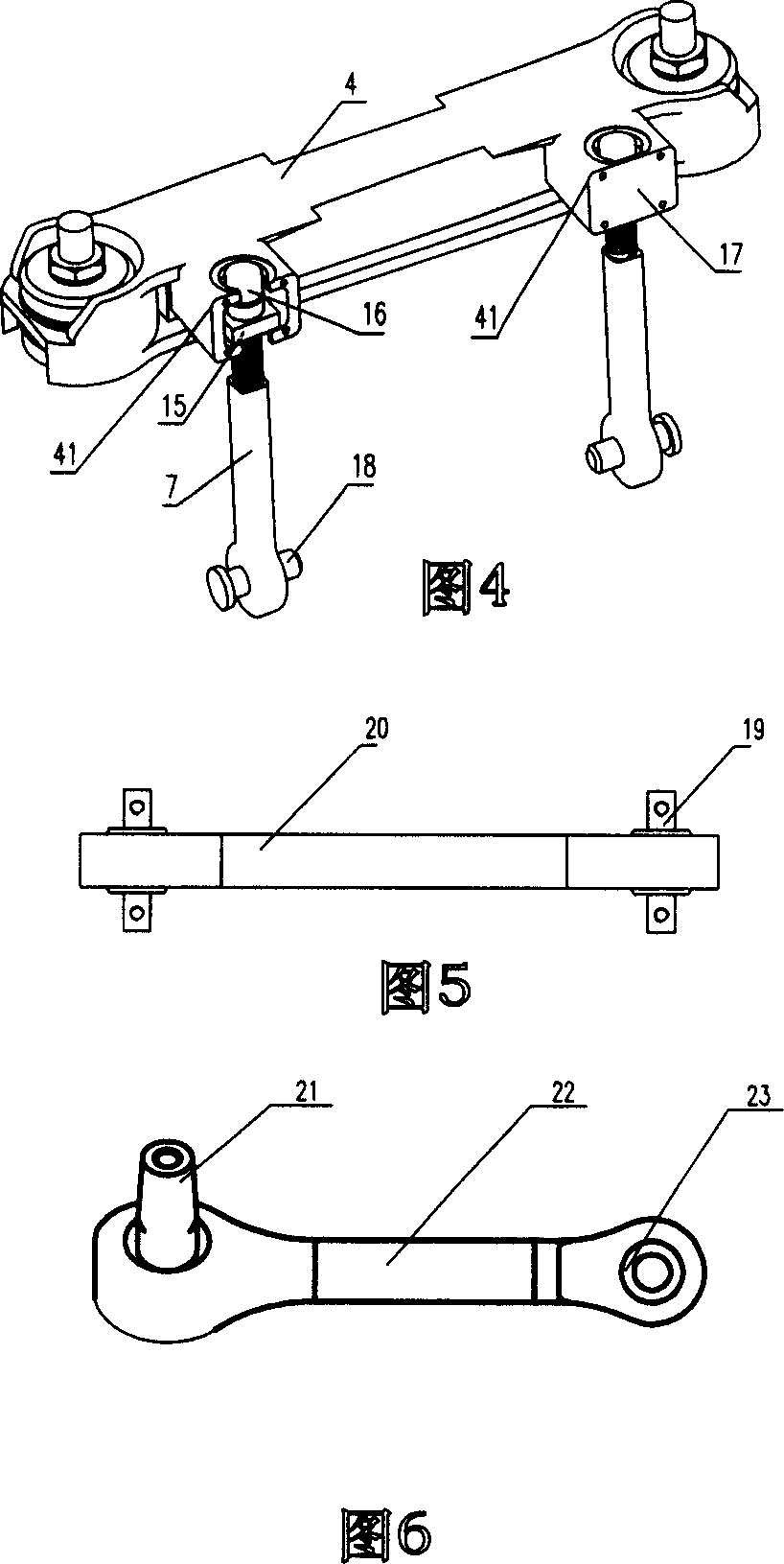

[0063] As shown in FIG. 4, a mou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com