Method for detecting and compensating for abrasion of grinding wheel automatically

An automatic detection and compensation method technology, which is applied in the direction of grinding machine parts, grinding/polishing equipment, workpiece feed movement control, etc., can solve the problems affecting workpiece positioning accuracy, low efficiency, and affecting machining accuracy, etc., to achieve Realize the effects of automation, high efficiency and guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

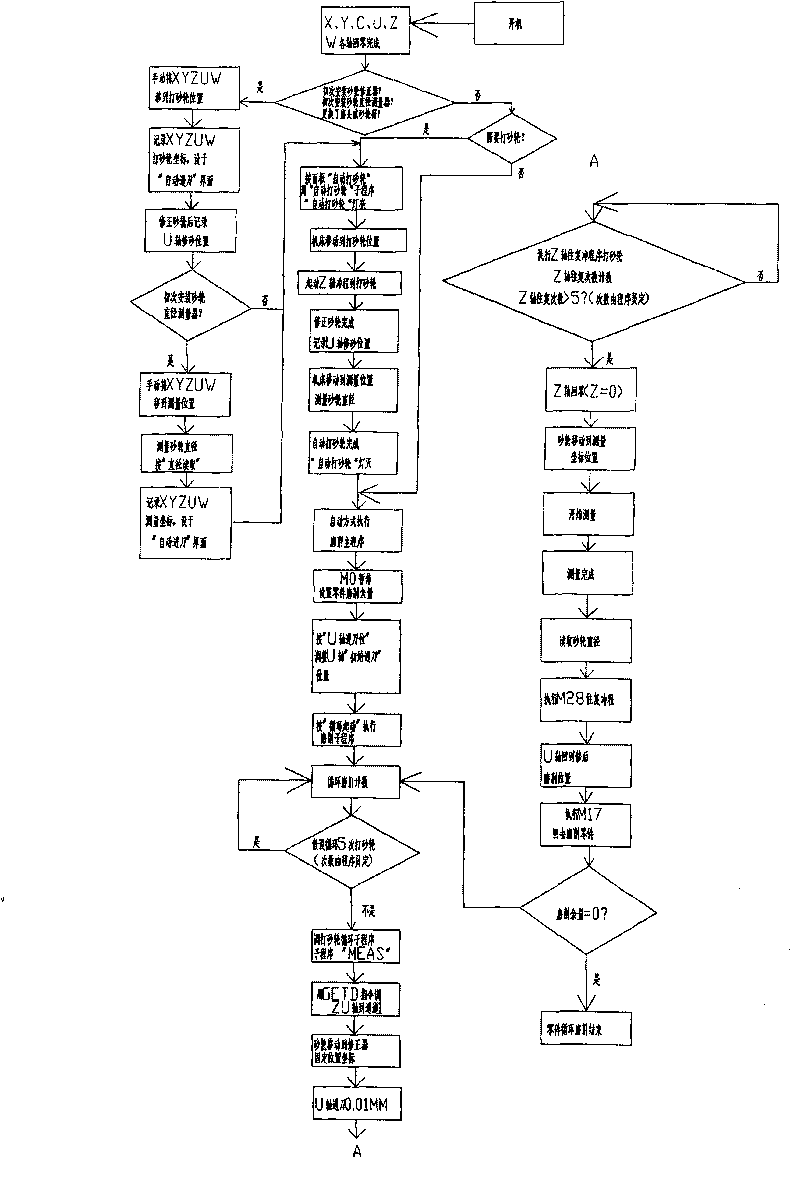

[0036] An automatic detection and compensation method for grinding wheel wear, characterized in that: a grinding wheel corrector is used to automatically correct the cycle of the grinding wheel after grinding, and a grinding wheel diameter detector is used to conduct online detection of the grinding wheel diameter in processing, and the grinding wheel diameter data obtained after detection Send it to the CNC system, and the CNC system compares the grinding wheel diameter data with the original grinding wheel diameter data, and obtains the grinding wheel wear amount and the grinding wheel correction amount (the consistency of the grinding wheel wear amount and the grinding wheel correction amount is related to the micrometer and machine tool accuracy), and the CNC system Control the feed amount of the machine tool (U-axis feed) to realize the automatic compensation of the grinding wheel. Wheel dressers and wheel diameter monitors are common devices on the market.

[0037] The m...

Embodiment 2

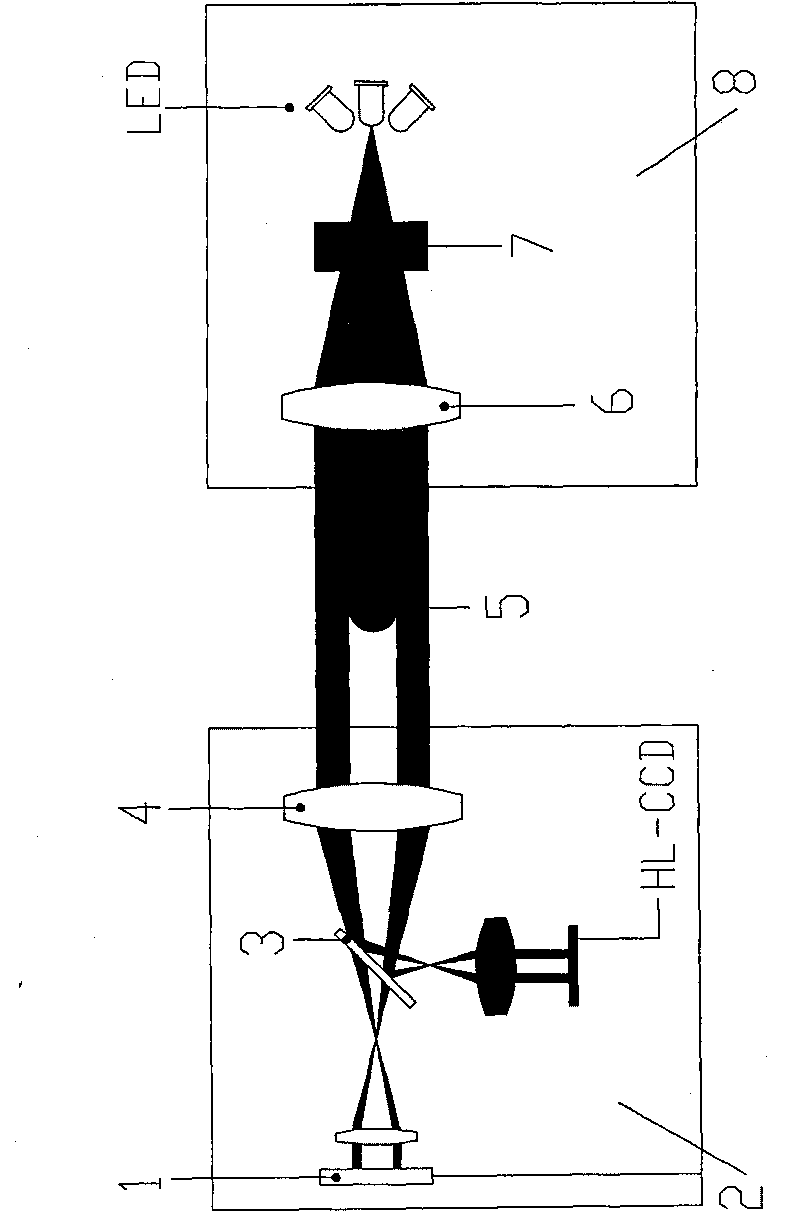

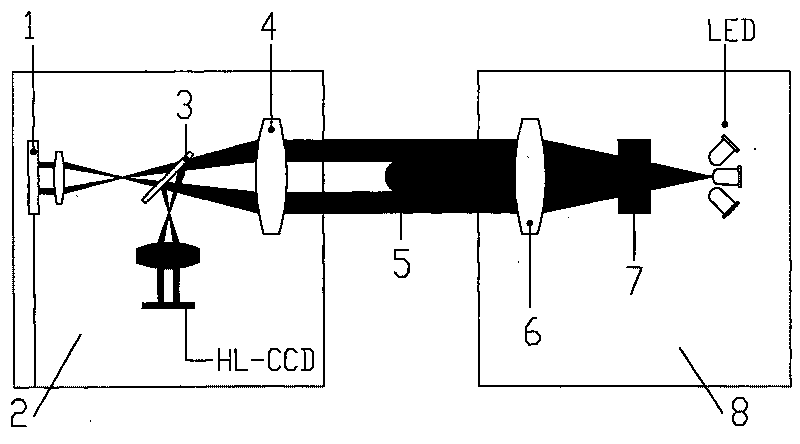

[0039] On the basis of Example 1, the grinding wheel diameter detector is an optical micrometer. (The optical micrometer is a commercially available device) The grinding wheel diameter detector is not only used for the detection of the grinding wheel diameter, but also for the detection and compensation control of the planetary grinding radius of the CNC jig grinder. The grinding wheel diameter detector is not only used for the detection of the grinding wheel diameter, but also for the detection and compensation control of the coincidence of the cutting edge of the grinding wheel with the continuous trajectory of the CNC coordinate grinding machine and the center of rotation of the C-axis. The grinding wheel diameter detector is not only used for the detection of the grinding wheel diameter, but also for the detection and compensation control of the thermal drift of the grinding spindle of the CNC coordinate grinding machine. According to the automatic grinding wheel correctio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com