Brake shoe wear automatic compensation device for hydraulic disc brake

A disc brake and automatic compensation technology, applied in the direction of brake type, slack adjuster, mechanical equipment, etc., can solve the problems of braking force failure, brake shoe wear, etc., and achieve the effect of constant brake shoe back distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

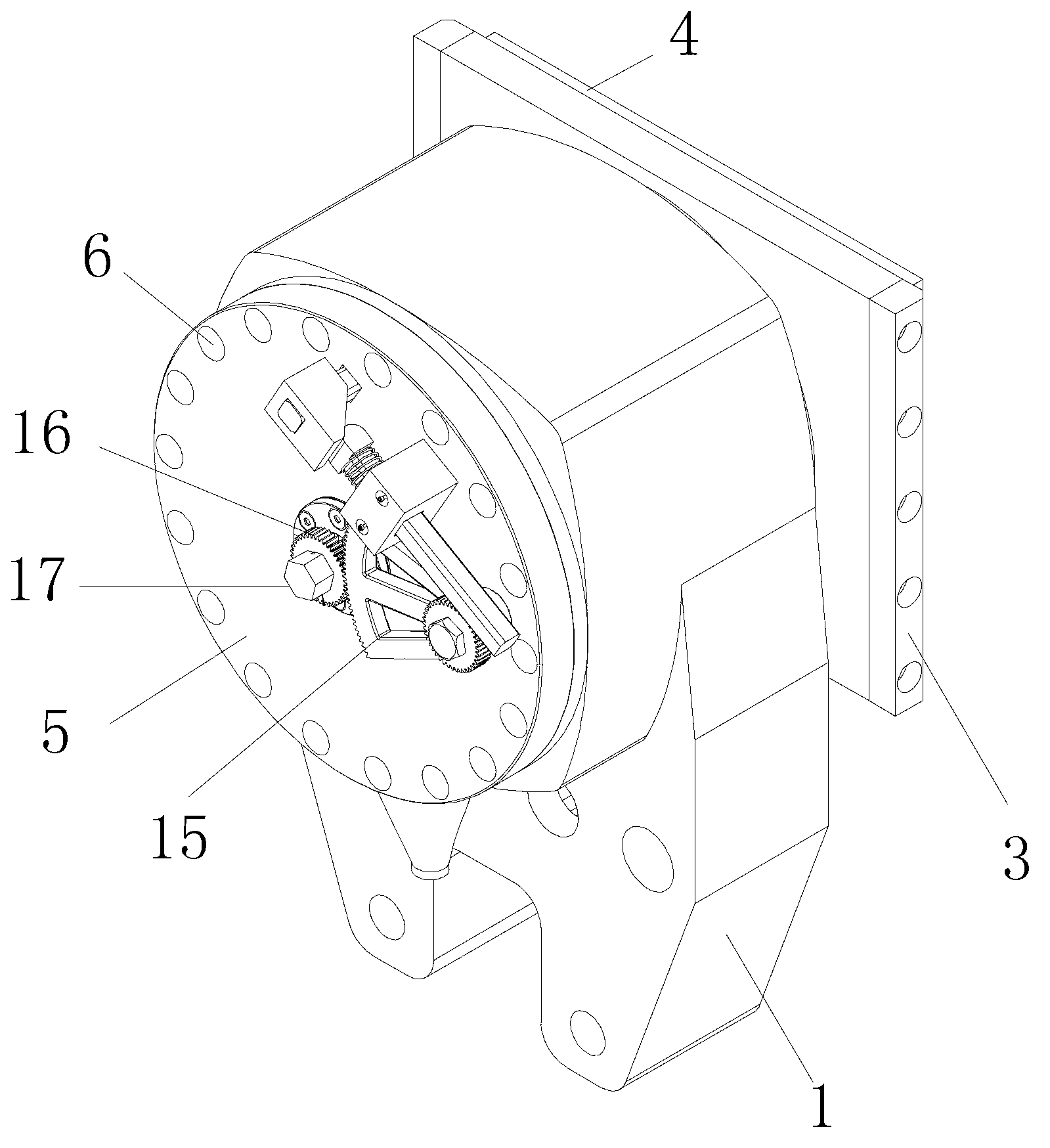

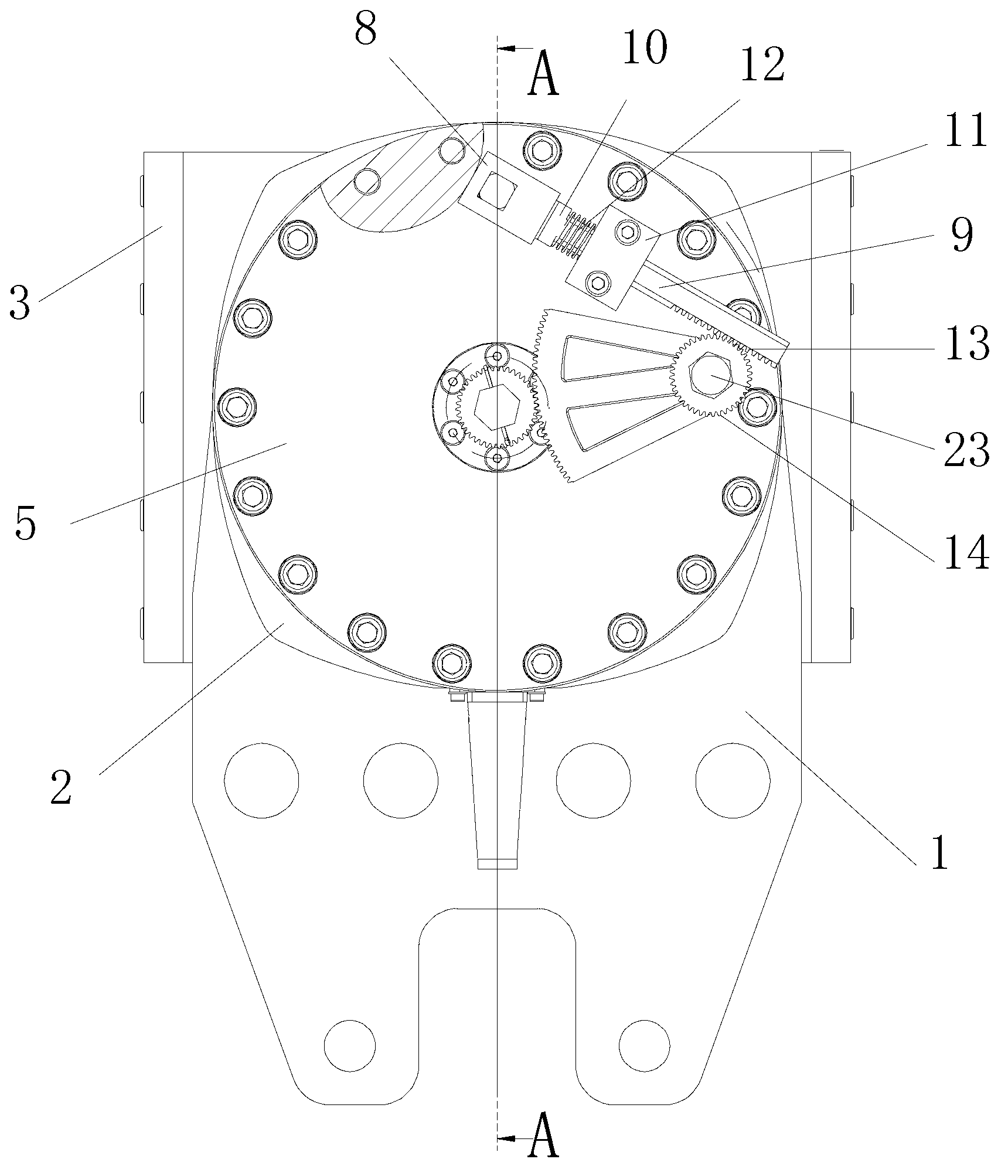

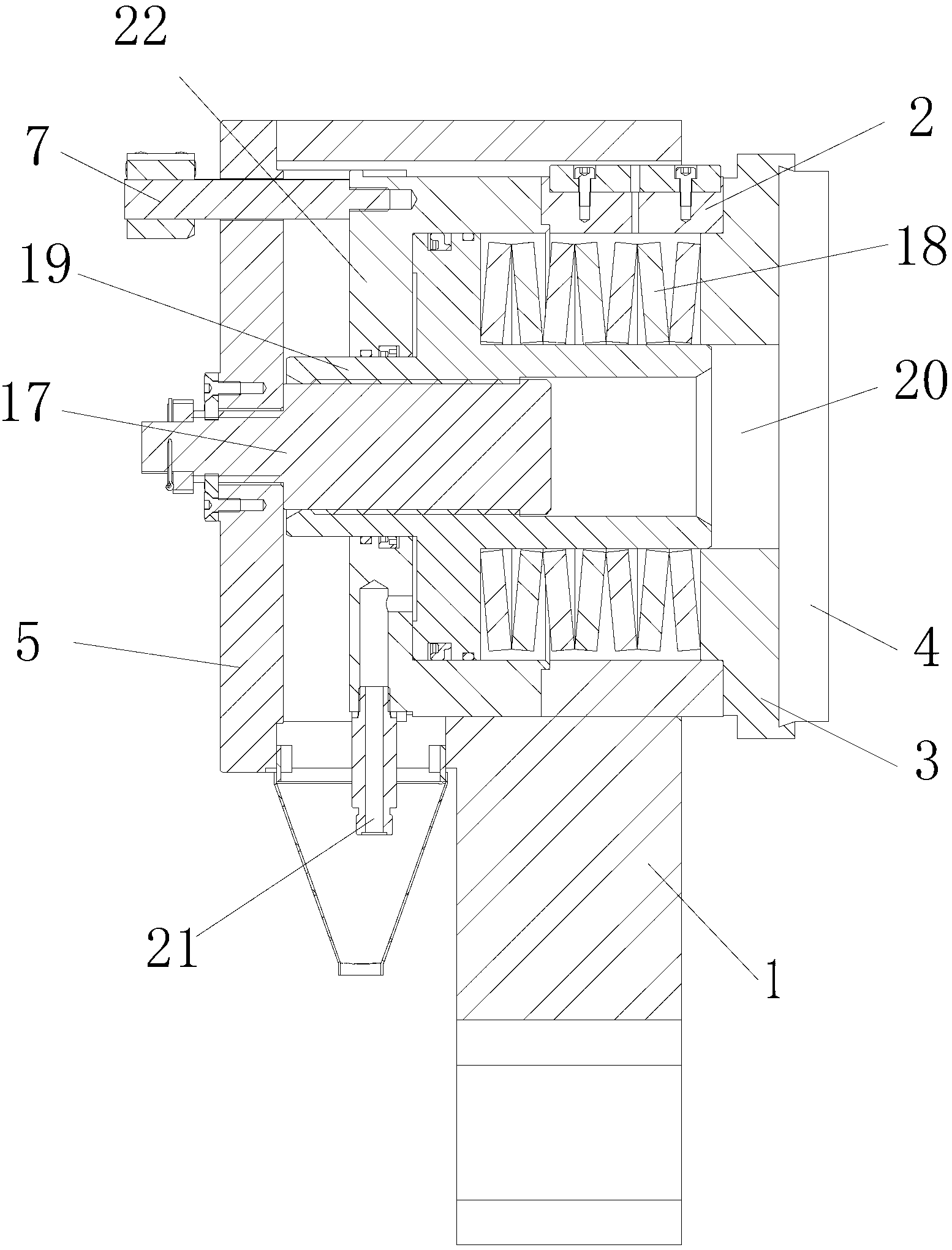

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

[0025] like Figure 1 to Figure 3 As shown, a brake shoe wear automatic compensation device for hydraulic disc brakes includes a frame 1, and an oil cylinder 2 is arranged on the frame 1; a cylinder head 22 is installed on one end surface of the oil cylinder 2, and the other There are brake shoes on the outside of the side end surface, the brake shoes are mainly composed of a brake seat 3 and a brake shoe 4, and the brake shoe 4 is installed on the brake seat 3; the middle position of the oil cylinder 2 is provided with a To the moving piston 19, one end of the piston 19 is provided with a rotating rod 17, and the other end is equipped with a piston rod 20, and the rotating rod 17 is a screw rod, and the above-mentioned brake seat 3 is socketed with the piston rod 20; 19 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com