Ram flexibility compensation mechanism of heavy numerical control floor type milling and boring machine

A compensation mechanism and floor-standing technology, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve problems such as deflection and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

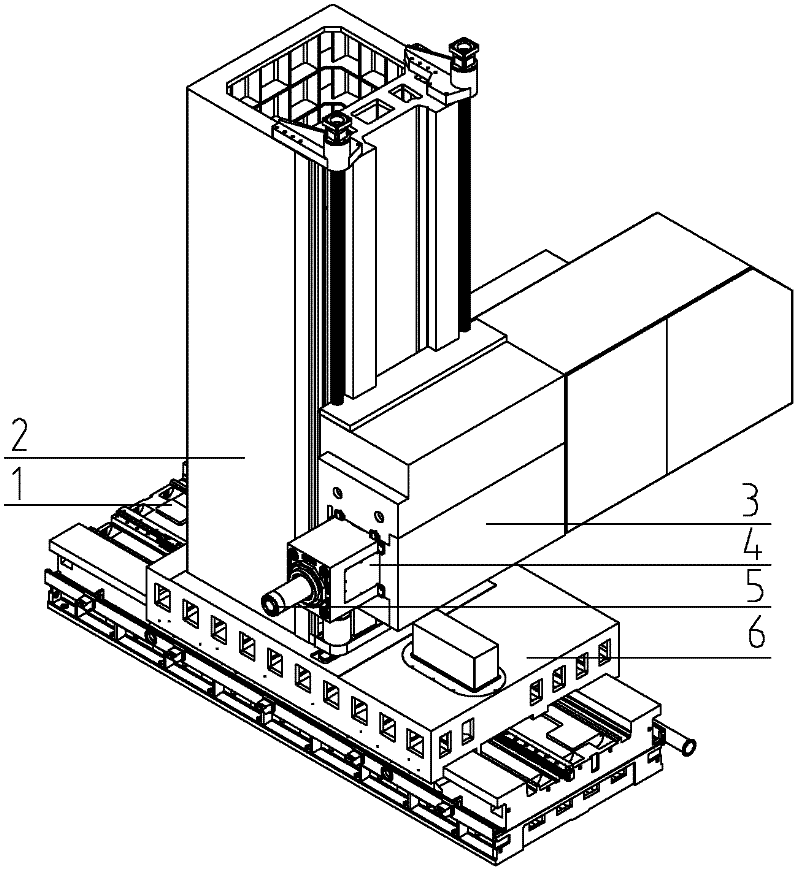

[0014] The structure of the existing CNC floor-type milling and boring machine is shown in figure 1 , the vertical column 2 is installed on the bottom bed 1 and the sliding seat 6, the headstock 3 is hung on the side elevation of the column 2, and the ram 4 in the horizontal state plays a role in connecting the headstock 3 and the main shaft in the CNC floor milling and boring machine 5 role. The ram 4 overall shape is a cuboid, and the four sides in the axial direction are guide rail surfaces, and a milling shaft and a boring shaft are installed inside. The ram and the boring shaft can move forward and backward. When the ram and the boring shaft protrude for a long time, the ram will bend and deform.

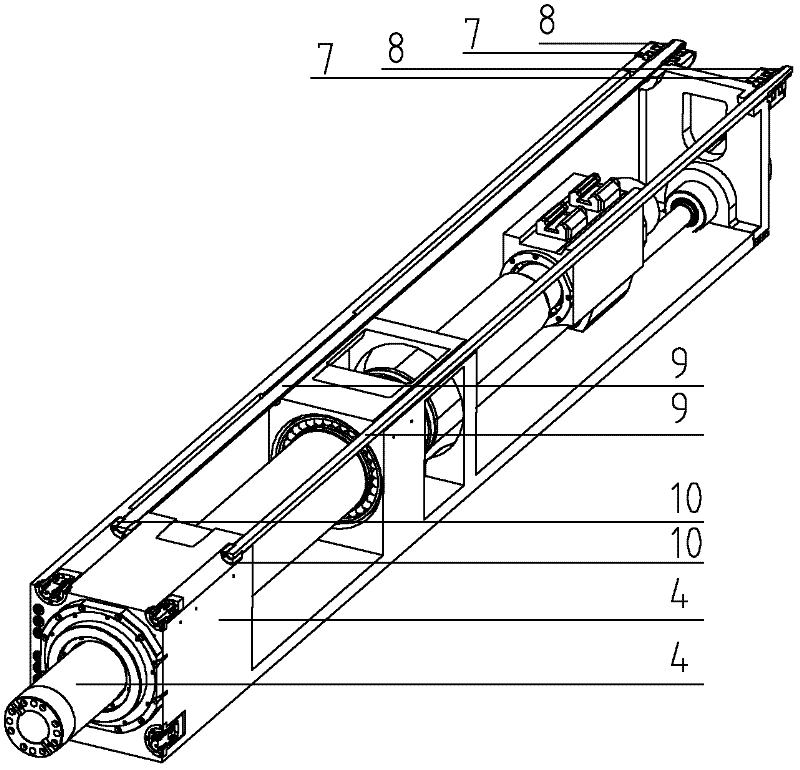

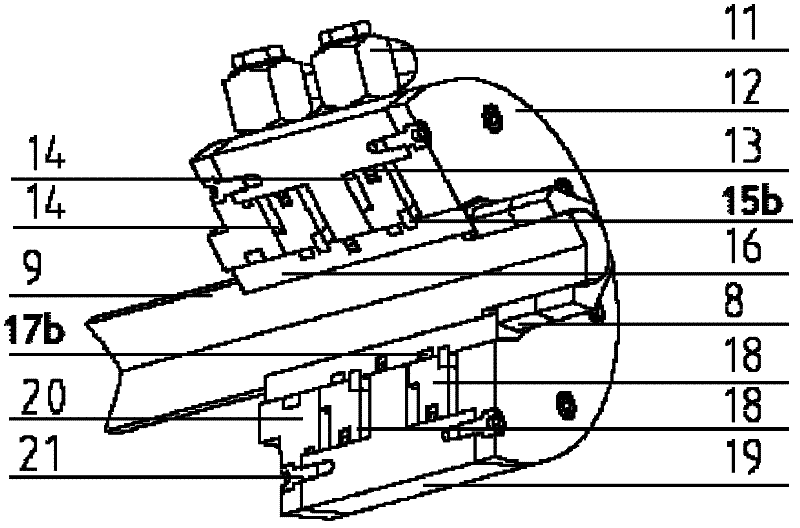

[0015] The ram deflection compensation mechanism of this heavy-duty CNC floor-type milling and boring machine of this design is characterized in that two tie rods 9 are installed at the upper two corners inside the ram 4 with a square cross-section, and the installation arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com