Polishing wheel diameter and polishing force detection method and polishing wheel wear compensating method

A detection method and wear compensation technology, which can be applied to grinding/polishing equipment, parts of grinding machine tools, metal processing equipment, etc., and can solve problems such as lag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

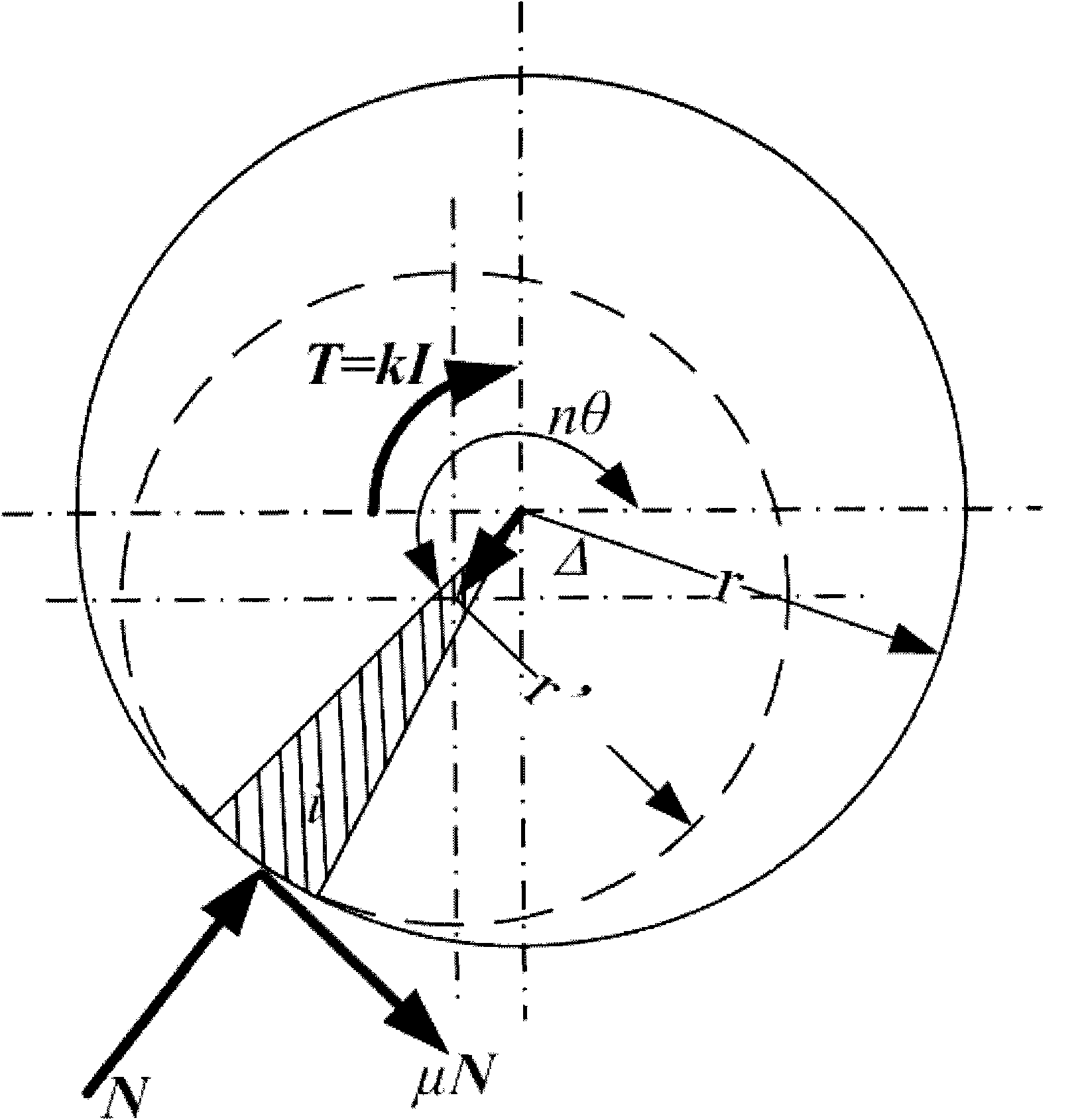

[0008] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0009] According to an embodiment of the present invention, a method for detecting the diameter of a polishing wheel is provided, which is characterized by comprising: detecting a current I flowing through a spindle motor driving the polishing wheel; and determining a diameter d of the polishing wheel according to the current.

[0010] According to a further embodiment of the present invention, the above-mentioned current I is the current flowing through the primary circuit of the spindle motor driving the polishing wheel.

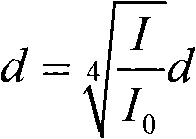

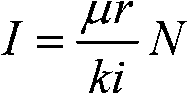

[0011] According to a further embodiment of the present invention, the above method is further characterized in that: a current sensor is used to detect the current I; the diameter d of the polishing wheel is determined according to the following formula:

[0012] d = I ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com