A kind of thermoplastic halogen-free flame-retardant polyphenylene ether elastomer cable material and preparation method thereof

The technology of polyphenylene ether elastomer and polyolefin elastomer is applied in the field of thermoplastic halogen-free flame retardant polyphenylene ether elastomer and its preparation field, which can solve the problems of high hardness and high production cost, achieve high toughness and improve comprehensive performance. , the effect of reducing insulation resistance and elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment provides a thermoplastic halogen-free flame-retardant polyphenylene ether elastomer cable material, which can be used for flexible wire and cable coating layers,

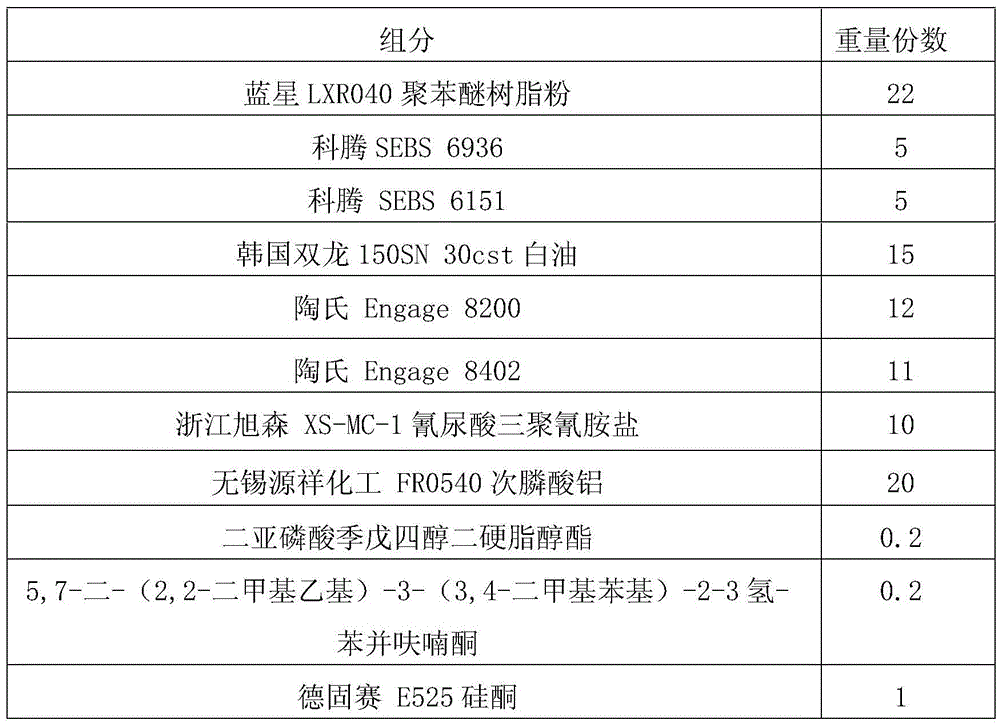

[0034] (1) The cable material is selected from the following components in parts by mass, as shown in Table 1 below:

[0035] Table 1 Example 1 Cable Material Components

[0036]

[0037] (2) The preparation method of the cable material:

[0038] Put all the components in the above table 1 into the high-speed mixer, firstly stir evenly in the high-speed mixer, and then extrude through the twin-screw extruder at a temperature range of 200°C, granulate with water strands, dry with moisture and then pack , Serve as a finished product of thermoplastic halogen-free flame-retardant polyphenylene ether elastomer cable material for flexible wire and cable coating.

[0039] In this embodiment, the kinematic viscosity of the plasticizer is between 50 cSt.

[0040] In this embodiment, the polypheny...

Embodiment 2

[0046] This embodiment provides a thermoplastic halogen-free flame-retardant polyphenylene ether elastomer cable material, which can be used for flexible wire and cable coating layers,

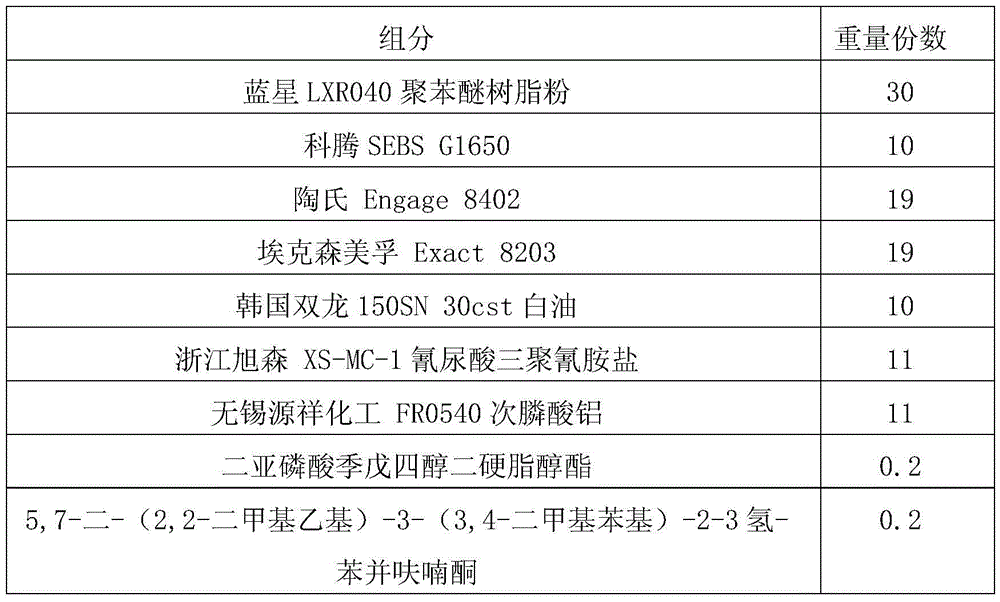

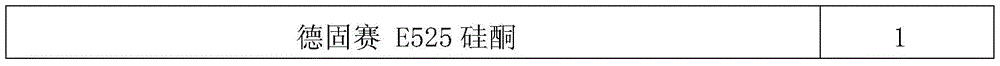

[0047] (1) The cable material selects the following components in parts by mass, as shown in Table 2 below:

[0048] Table 2 Example 2 Cable Material Components

[0049]

[0050]

[0051] (2) The preparation method of the cable material:

[0052] Put all the components in the above table 2 into the high-speed mixer, firstly stir evenly in the high-speed mixer, and then extrude through the twin-screw extruder at a temperature range of 180°C, granulate with water strands, dry with moisture and then pack , Serve as a finished product of thermoplastic halogen-free flame-retardant polyphenylene ether elastomer cable material for flexible wire and cable coating.

[0053] In this embodiment, the kinematic viscosity of the plasticizer is between 20 cSt.

[0054] In this embodiment, the polyph...

Embodiment 3

[0060] This embodiment provides a thermoplastic halogen-free flame-retardant polyphenylene ether elastomer cable material, which can be used for flexible wire and cable coating layers,

[0061] (1) The cable material is selected from the following components in parts by mass, as shown in Table 3 below:

[0062] Table 3 Example 3 Cable Material Components

[0063]

[0064]

[0065] (2) The preparation method of the cable material:

[0066] Put all the components in the above table 3 into the high-speed mixer, firstly stir evenly in the high-speed mixer, and then extrude through the twin-screw extruder at a temperature range of 210°C, granulate with water strands, dry with moisture and then pack , Serve as a finished product of thermoplastic halogen-free flame-retardant polyphenylene ether elastomer cable material for flexible wire and cable coating.

[0067] In this embodiment, the kinematic viscosity of the plasticizer is between 65 cSt.

[0068] In this embodiment, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

| kinematic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com