Testing device and testing method for simulating mechanical properties of marine energy soil-well interface in hydrate exploitation process

A technology of mining process and interface mechanics, applied in earthwork drilling, wellbore/well components, etc., can solve problems such as inability to simulate natural gas hydrate mining process, achieve high degree of automation, reduce manual errors, and high data acquisition accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

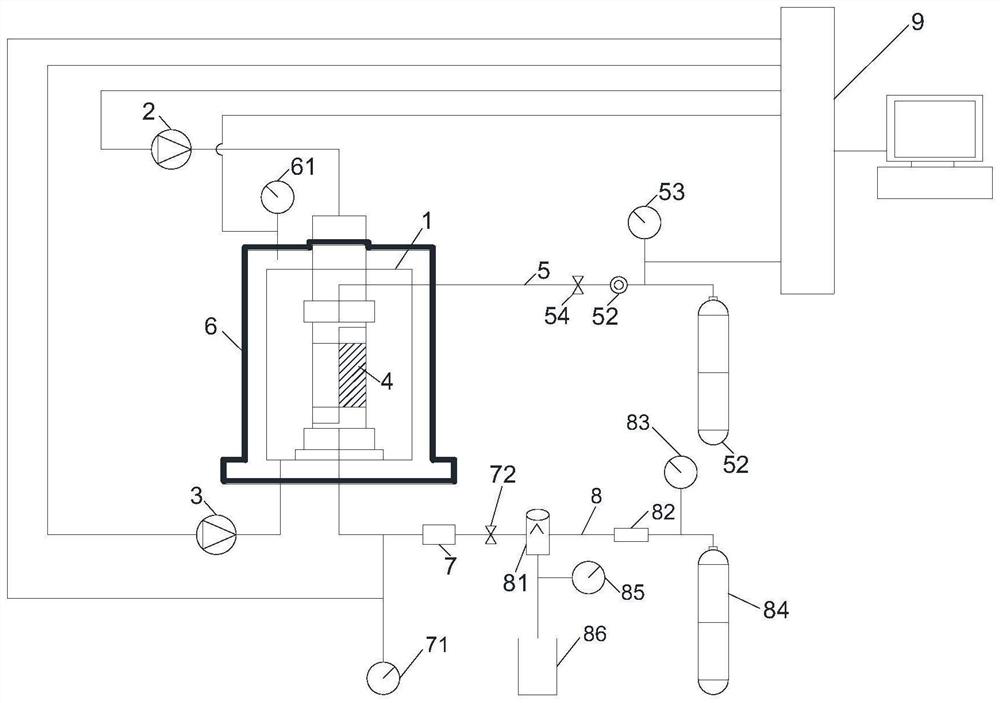

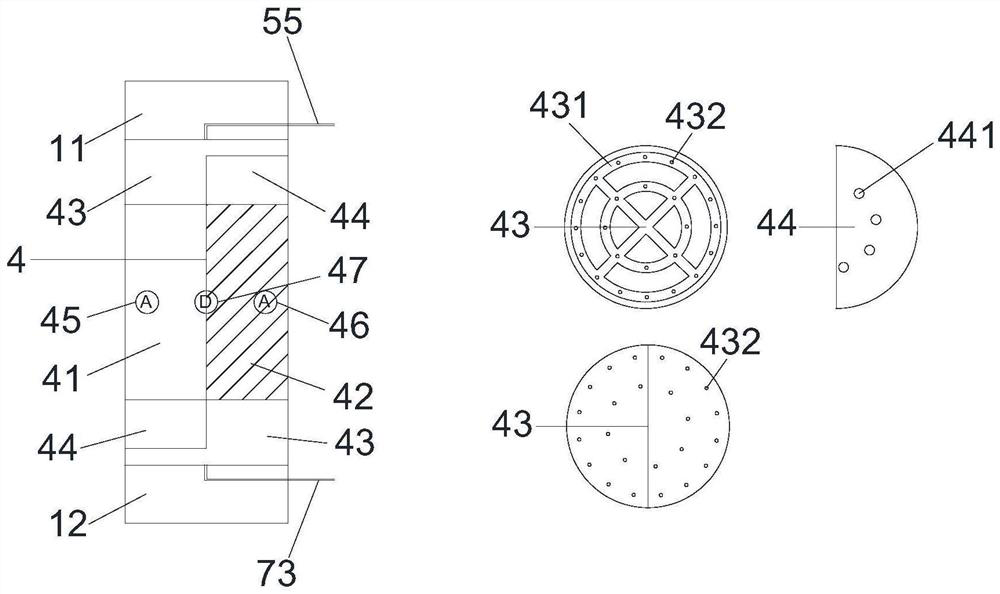

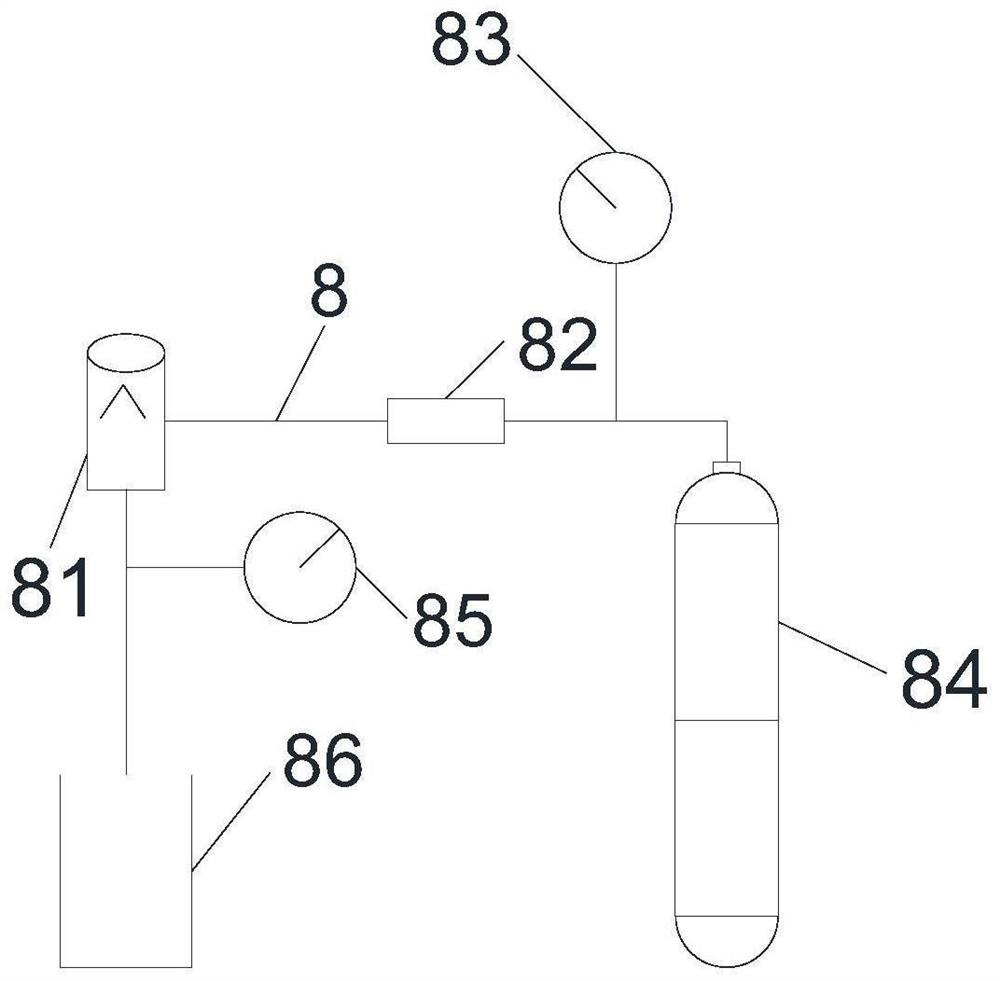

[0017] Such as figure 1 As shown, the test device for simulating the mechanical properties of the ocean energy soil-well interface in the process of hydrate exploitation includes: triaxial pressure chamber 1, axial pressure loader 2, confining pressure loader 3, soil-well interface shear sample 4 , air supply and pressure regulating system 5, water bath tank 6, back pressure valve 7, gas-liquid separation and recovery device 8 and data acquisition system 9; wherein: stress loading systems 2 and 3 are connected with triaxial pressure chamber 1 to realize loading in different stress modes The gas supply and pressure regulating system 5 is connected to the triaxial pressure chamber 1 to provide the gas source and control the pressure of the gas; the water bath tank 6 seamlessly surrounds the triaxial pressure chamber 1 to control the temperature in the confining pressure chamber to realize the stable formation or hydration of hydrates The temperature rises and decomposes; the soi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com