Steamer generator stator core welding deformation controlling means

A technology of steam turbine generator and stator iron core, which is applied in welding medium, welding equipment, welding equipment and other directions, can solve the problems such as out-of-tolerance inner diameter of stator iron core, deviation of welding process parameter selection, inconsistent inner diameter of stator iron core, etc. Achieve the effect of ensuring operation safety, controlling welding deformation, and effective welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

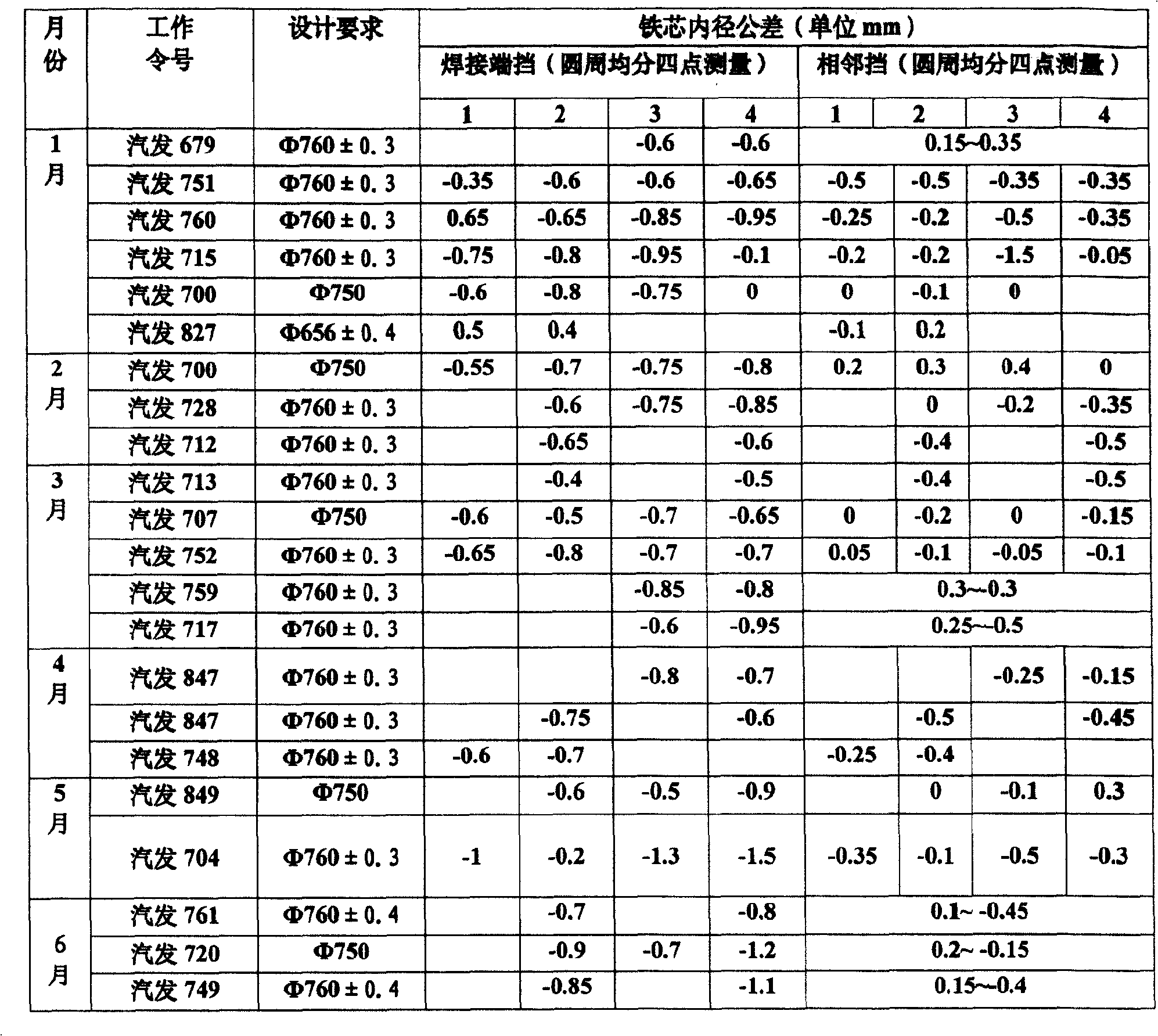

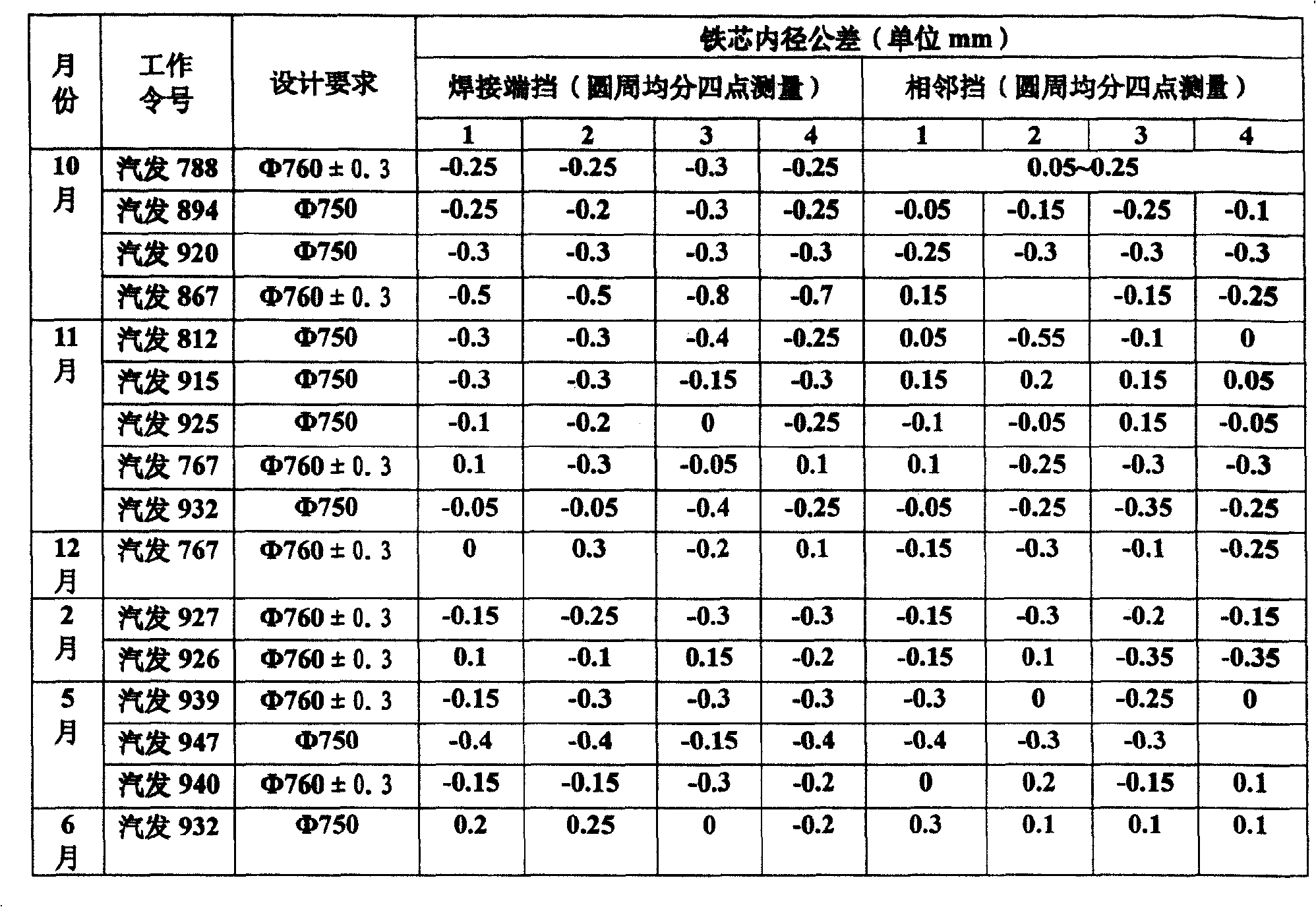

Image

Examples

Embodiment 1

[0015] Embodiment 1: A method for controlling welding deformation of a turbogenerator stator core, the control process of which is as follows:

[0016] A. Choose CO with a purity of 99.5% 2 Shielded welding gas and Φ1.2 H08Mn2SiA welding wire, the gas pressure is controlled at 0.2-7MPa during welding;

[0017] B. The first segmented symmetrical multi-layer welding is performed on the stator core of the turbogenerator at a welding speed of 25m / h, the welding current is controlled to 180A, and the arc voltage is controlled to 25V;

[0018] C. Carry out the second segmented symmetrical multi-layer welding on the stator core of the turbogenerator at a welding speed of 25m / h, the welding current is controlled to 350A, and the arc voltage is controlled to 32V;

[0019] D. The third segmented symmetrical multi-layer welding is performed on the stator core of the turbogenerator at a welding speed of 25m / h. The welding current is controlled to 280A and the arc voltage is controlled to...

Embodiment 2

[0025] Embodiment 2: A method for controlling the welding deformation of the stator core of the turbogenerator. The steps for controlling the welding deformation of the stator core of the turbogenerator are as follows:

[0026] B. Choose CO with a purity of 99.5% 2 Shielded welding gas and Φ1.2H08Mn2SiA welding wire, the gas pressure is controlled at 0.2-7MPa during welding;

[0027] C. The first segmented symmetrical multi-layer welding is performed on the stator core of the turbogenerator at a welding speed of 25m / h, the welding current is controlled to 160A, and the arc voltage is controlled to 22V;

[0028] D. Carry out the second segmented symmetrical multi-layer welding on the stator core of the turbogenerator at a welding speed of 25m / h. The welding current is controlled to 320A and the arc voltage is controlled to 30V;

[0029] E. The third segmented symmetrical multi-layer welding is performed on the stator core of the turbogenerator at a welding speed of 25m / h. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com