A cladding installation method and welding process of duplex stainless steel pool in nuclear power plant

A duplex stainless steel and installation method technology, which is applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of low welding efficiency, high requirements for assembly, and difficulty in guaranteeing welding quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with specific examples.

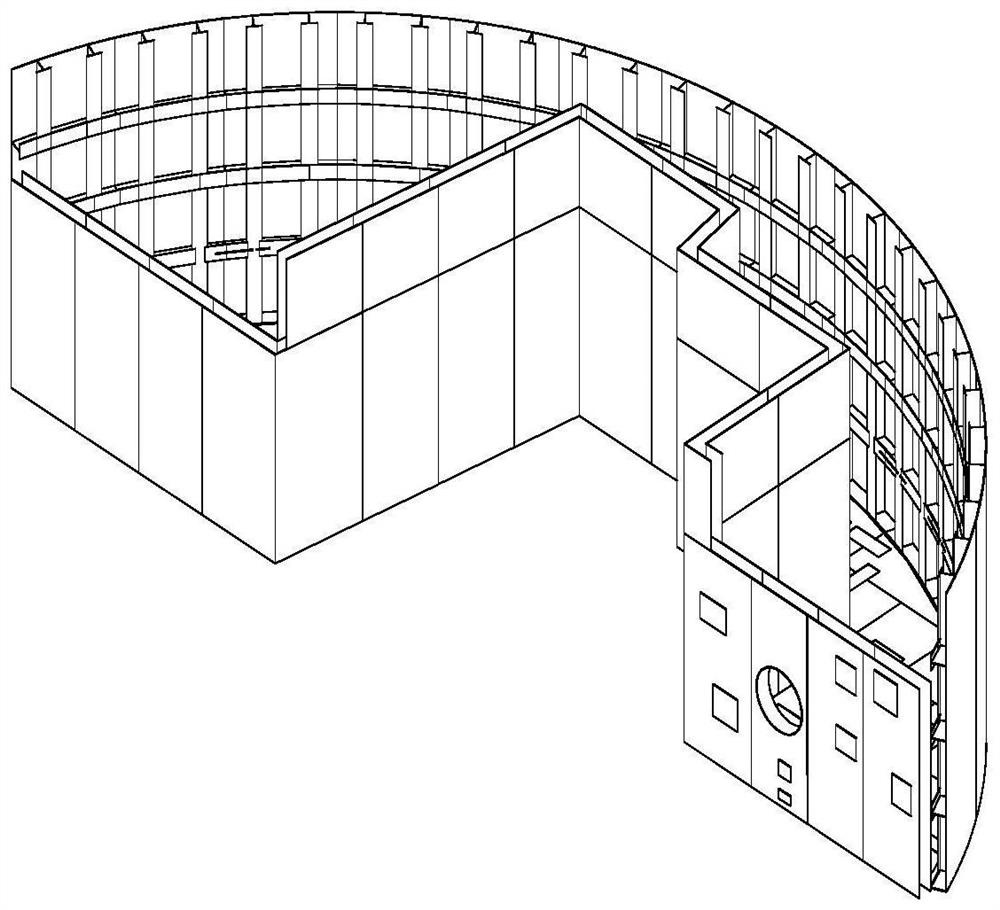

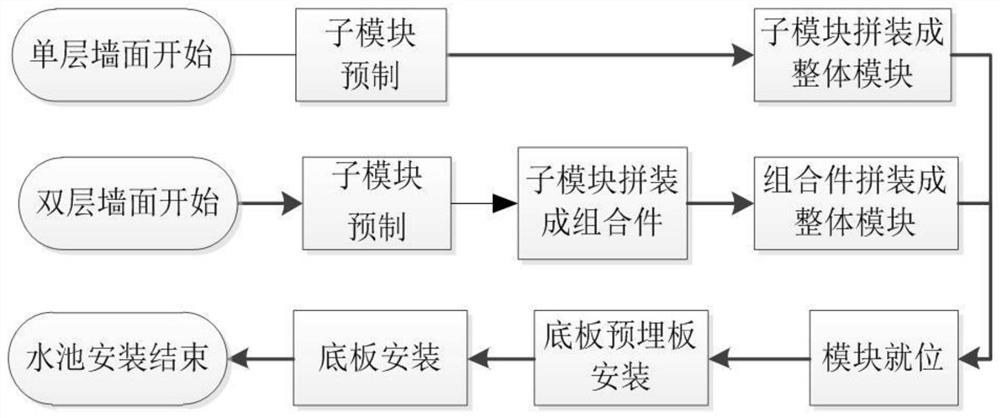

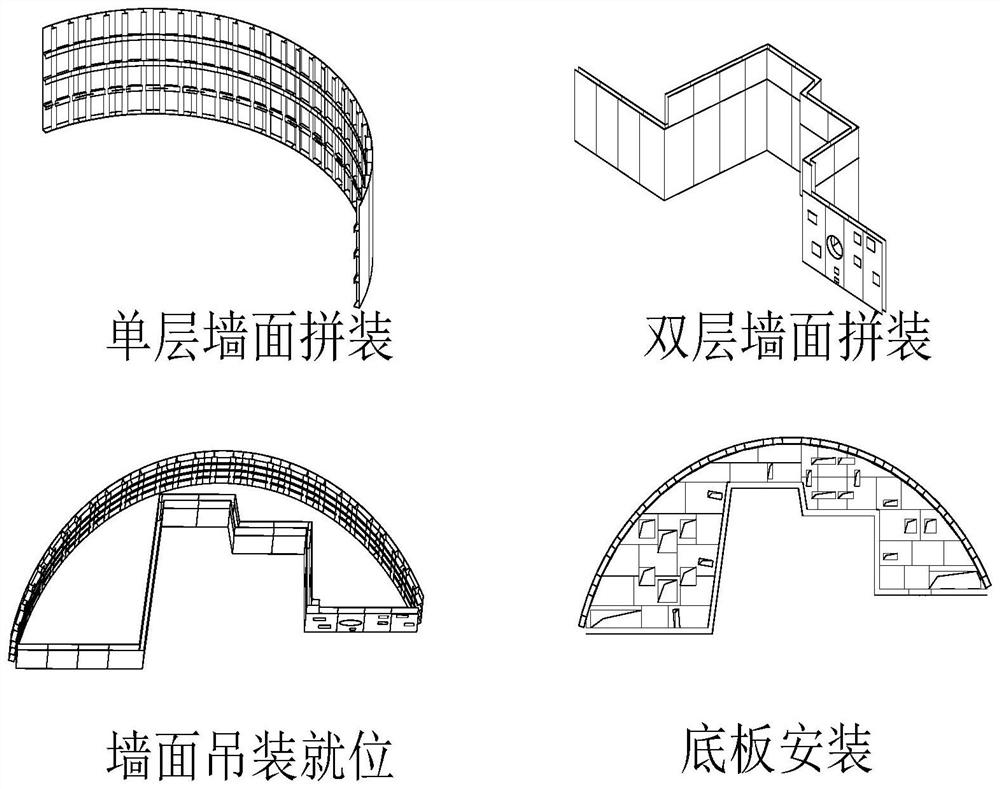

[0032] A method for installing the cladding of a duplex stainless steel pool in a nuclear power plant. The pool cladding is made of A240S32101 duplex stainless steel. According to the structure of the pool, the cladding installation of the pool is divided into two parts: the wall and the floor; the wall cladding adopts a modular manufacturing method. Pre-assembled on site, hoisted in place after assembly, installed inside the nuclear power plant, and then installed the pool floor cladding;

[0033] The installation of the wall cladding includes the installation of a single-layer wall cladding and the installation of a double-layer wall cladding, which is selected as a part of the installation of a single-layer wall cladding or a part of the installation of a double-layer wall cladding according to the specific structure of the stainless steel pool; The installation of the sing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com