Welding tool for thin-wall case

A welding tool and chassis technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as difficulty in controlling deformation, affecting work efficiency, and inconvenient operation of welding tools, so as to achieve convenient operation and guarantee Welding accuracy, the effect of controlling welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

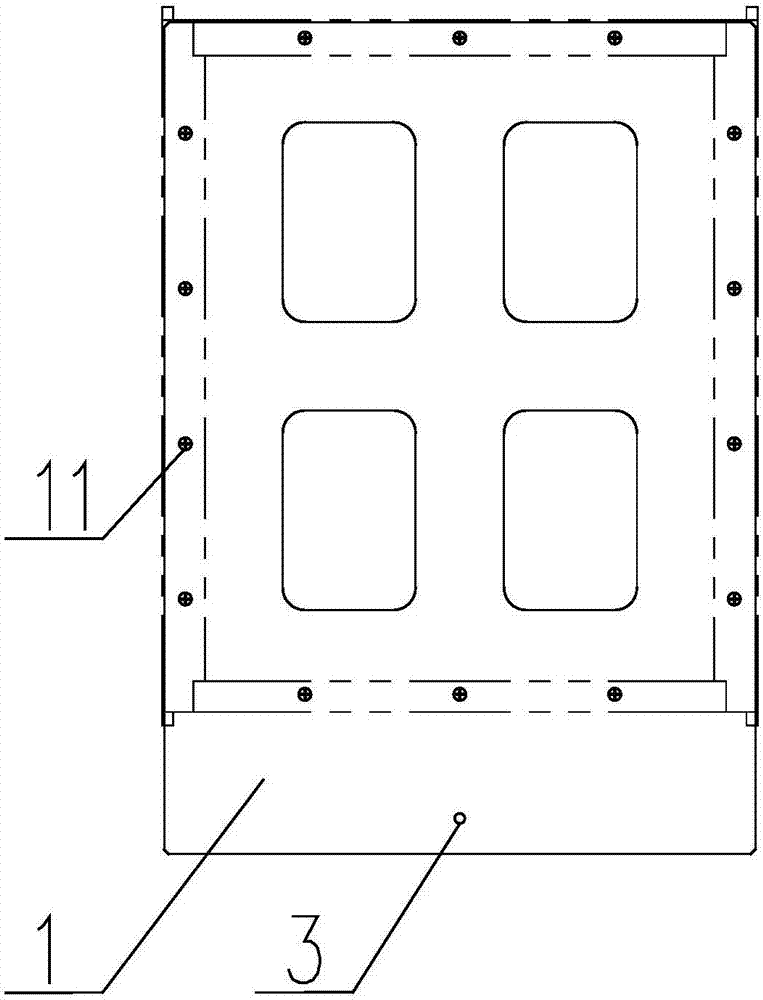

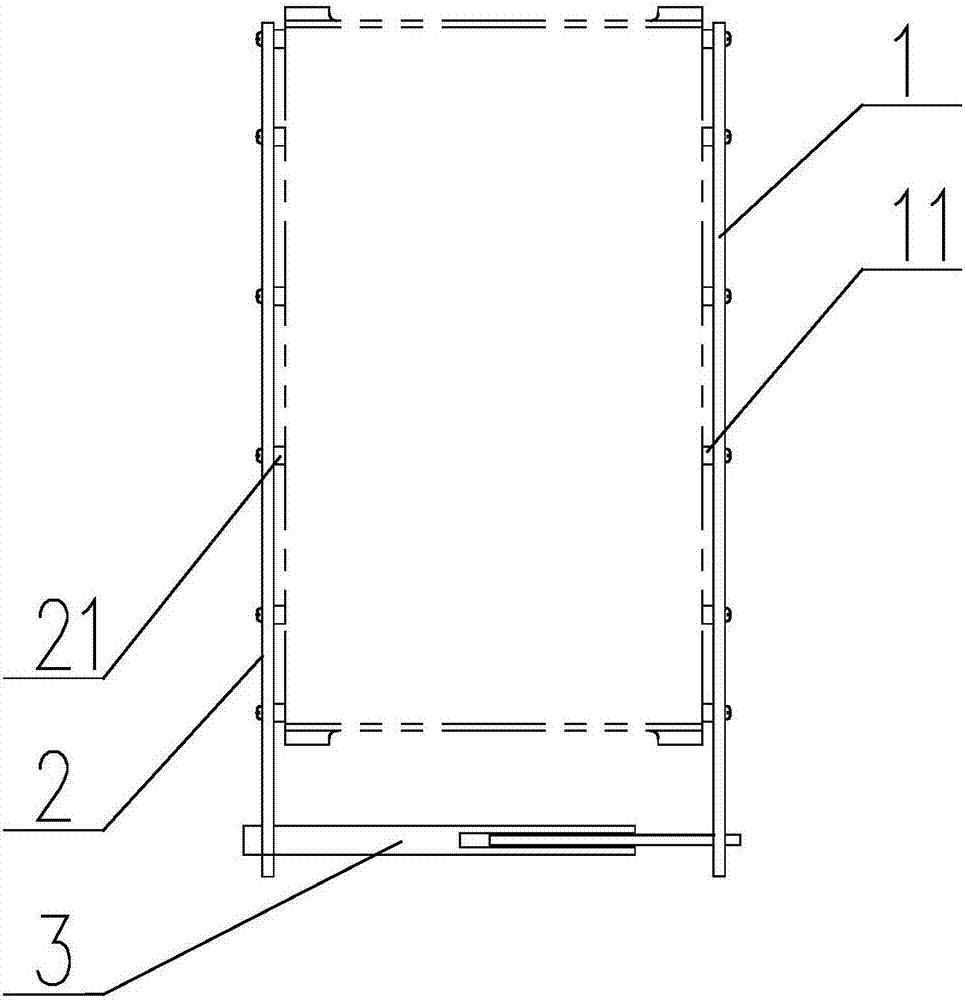

[0013] The present invention as Figure 1-2 As shown, it includes an upper clamping plate 1, a lower clamping plate 2, several upper clamping blocks 11 and several lower clamping blocks 21, the upper clamping blocks 11 are detachably connected to the end face of the upper clamping plate 1 facing the lower clamping plate 2, and the lower clamping The block 21 is detachably connected to the end face of the lower splint 2 facing the upper splint 1;

[0014] The welding tool also includes a telescopic rod 3, and the upper splint 1 and the lower splint 3 are parallel and facing to each other. There are many straight rods in the prior art, so the details will not be repeated in this case) One end is connected to the upper splint 1, and the other end is connected to the lower splint 2. During specific use, the distance between the upper splint and the lower splint is adjusted by the telescopic rod, so that the thin-walled case is stably clamped between the upper splint and the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com