A control method for welding deformation of large-size super-thick bridge steel tower pressure-bearing plate

A technology for welding deformation and bridge steel towers, applied in welding equipment, manufacturing tools, metal processing equipment, etc., to achieve the effect of reducing the amount of follow-up correction, reducing welding deformation, and ensuring mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

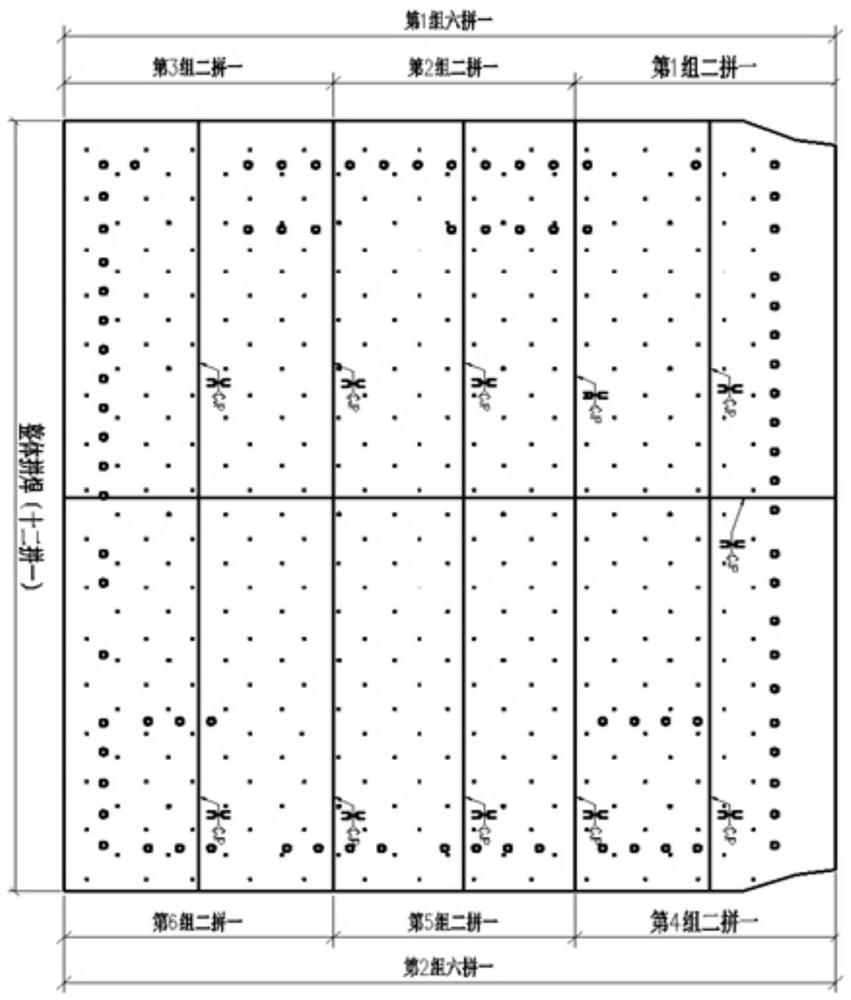

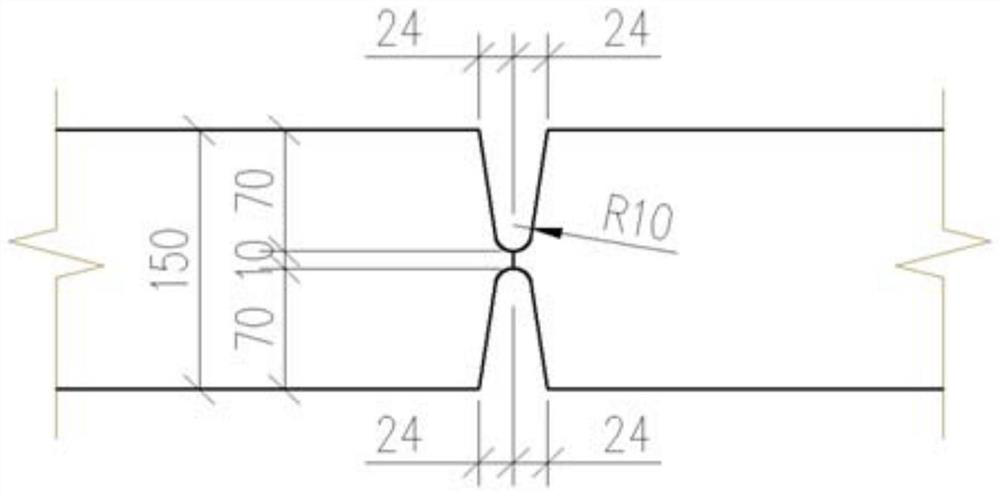

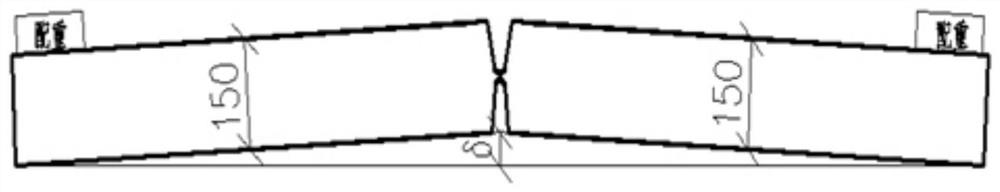

[0024] combined with figure 1 , 2 , 3, 4 describe an embodiment of the present invention.

[0025] 1. Through structural analysis, determine a reasonable unit division scheme.

[0026] Taking the structural size of the pressure plate of about 150mmX14650mmX15850mm as an example, its total weight is about 273.4t. According to the market research, the supply capacity of steel mills with t150mm is 25t. Therefore, the division units of the pressure plate should be no less than 11 pieces.

[0027] If the pressure-bearing plate is divided into 11 pieces with full-length longitudinal welds, the shortest length of the welds is: 10 pieces × 14.65m = 146.5m; if the pressure-bearing plate is divided into 12 pieces with vertical and horizontal welds, the length of the welds For: 5 × 15.85m+1 × 14.65 = 93.9m. Therefore, the longitudinal and horizontal division of the weld seam length of the pressure plate will reduce about 50%, which has a great effect on the construction workload and w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com