Tailor-welding device and tailor-welding method for inner-layer connecting ring of low-temperature wind tunnel

A connecting ring and inner layer technology, applied in welding/welding/cutting items, auxiliary devices, welding equipment, etc., can solve the problem of low manufacturing accuracy of the inner layer connecting ring, improve manufacturing efficiency, control welding deformation, and prevent deformation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

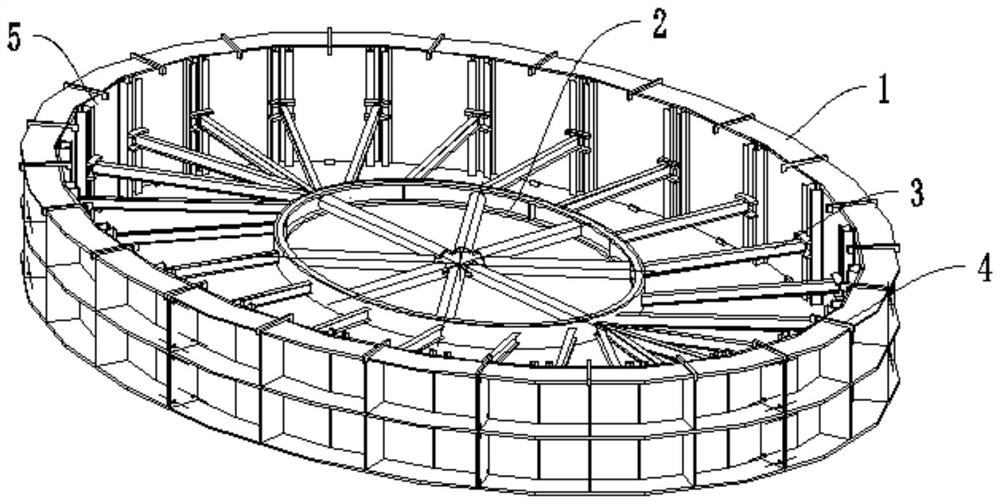

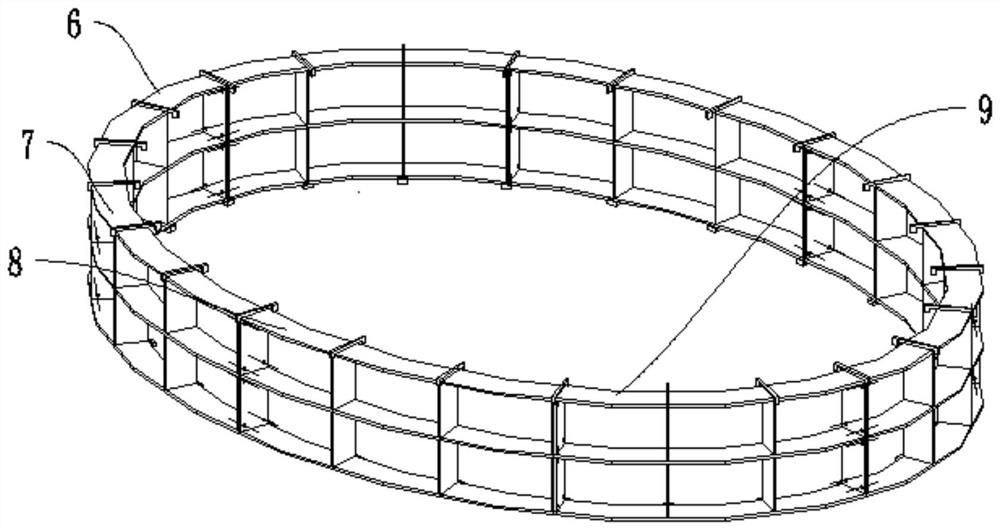

[0040] Please refer to figure 1 , with reference to Figure 2 to Figure 7 , the application provides a low-temperature wind tunnel inner layer connecting ring tailor welding device, through which the inner layer connecting ring 5 of the low temperature wind tunnel is formed and welded, the assembly accuracy of the inner layer connecting ring 5 can be effectively guaranteed and the welding can be controlled deformation in the process.

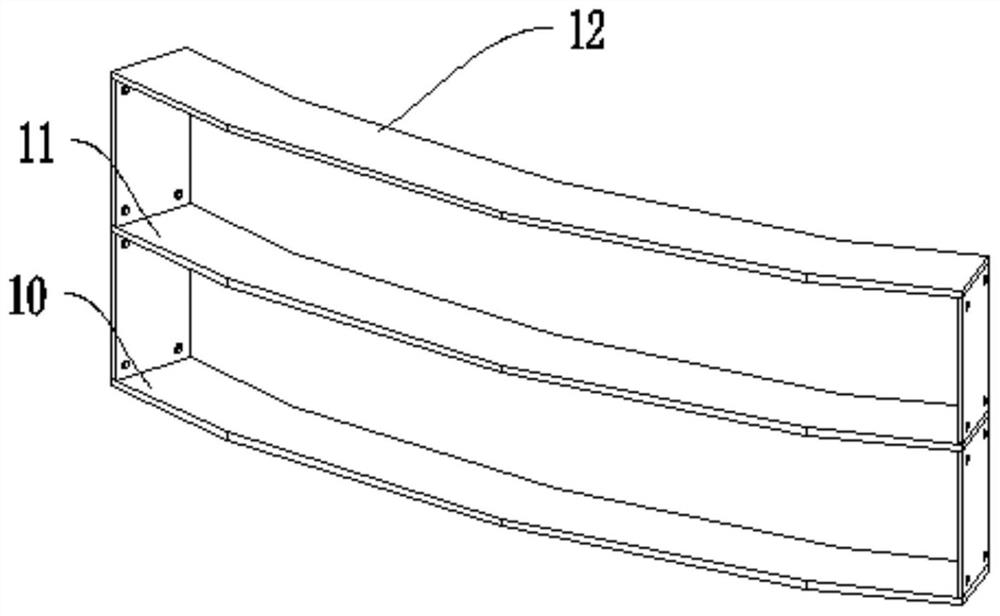

[0041] The assembly device mainly includes an elliptical frame mold 1, an elliptical frame 2, a rigid support component 3 and a fastening component 4; wherein, the elliptical frame mold 1 is an elliptical ring-shaped twenty-four-sided structure, and is used to be socketed on On the peripheral wall of the inner layer connecting ring 5 of the elliptic annular shape, the inner profile surface of its structure is a working surface, and the size of the inner profile surface is identical with the size of the inner layer connecting ring 5 outer wall s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com