A deep U-shaped rotary cross-section semi-closed flame cylinder assembly welding processing method

A semi-closed, processing method technology, applied in deep U-shaped rotary cross-section semi-closed flame tube assembly welding processing, turbojet engine parts processing field, can solve the difficult to guarantee shape and position tolerance and dimensional accuracy, high shape and position tolerance And dimensional accuracy requirements, the difficulty of positioning and clamping parts, etc., to achieve the effect of low processing difficulty, stable product properties, and control of welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The features and performances of the present invention will be further described in detail below in conjunction with the accompanying drawings.

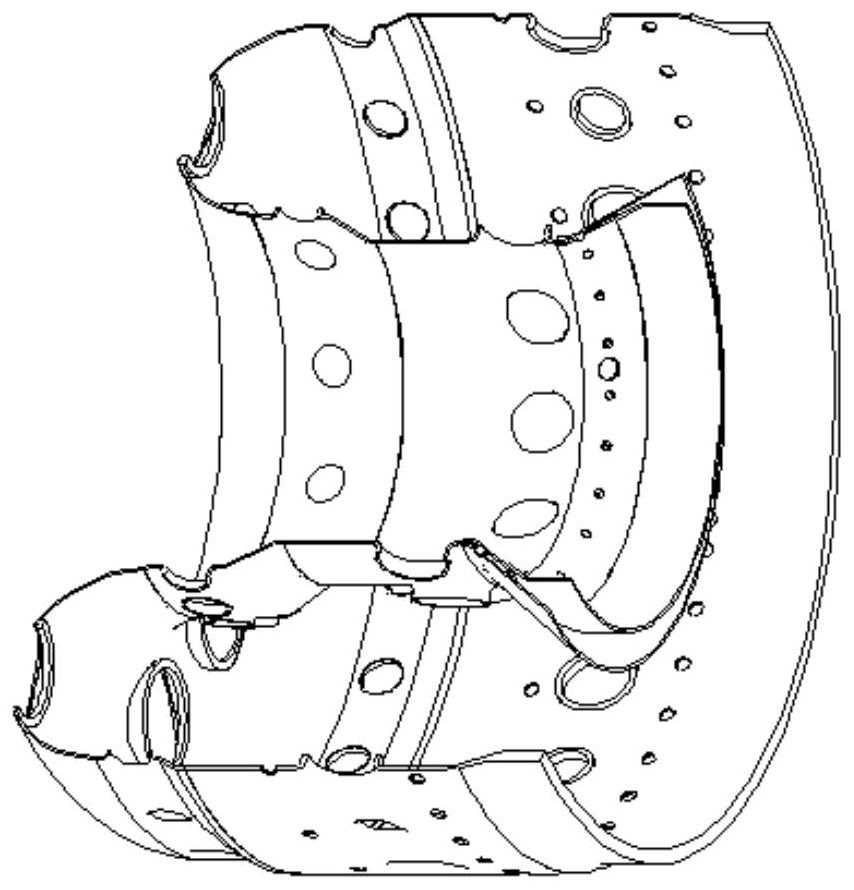

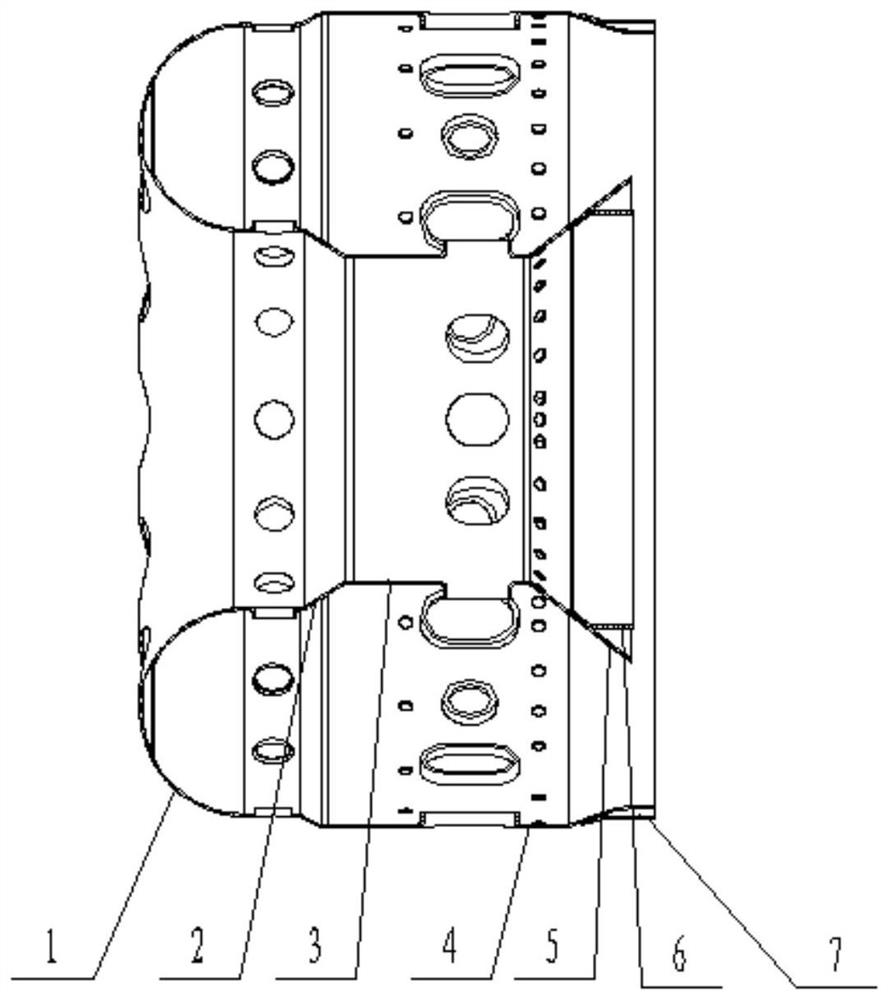

[0044] The structure of the deep U-shaped rotary section semi-closed flame tube is as follows: figure 2 and image 3 shown.

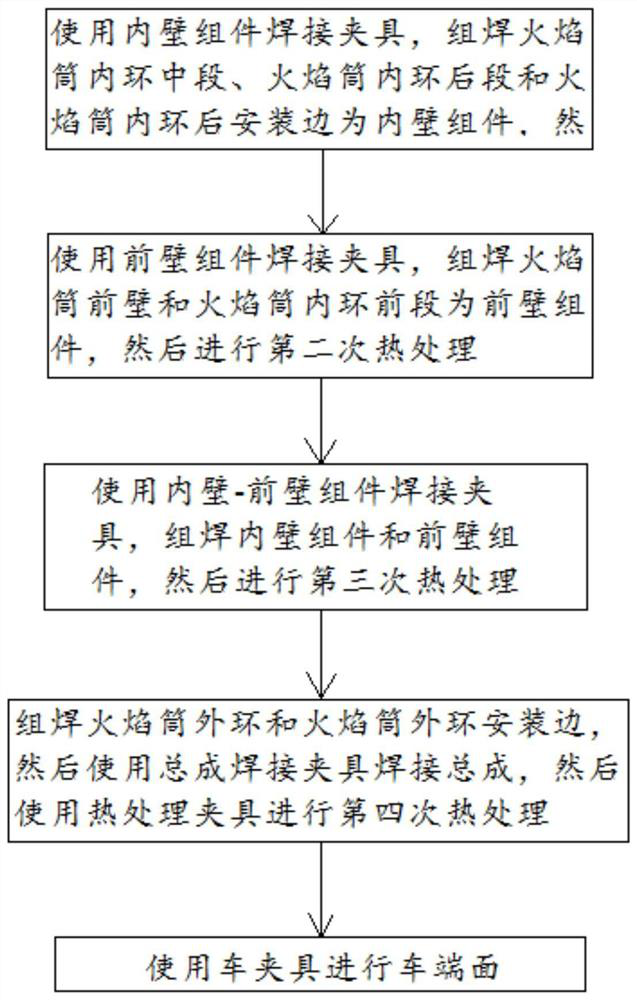

[0045] Such as figure 1 As shown, a deep U-shaped rotary section semi-closed flame cylinder assembly welding processing method includes the following steps:

[0046] S1. Use the welding jig 8 of the inner wall component, assemble and weld the middle section 3 of the inner ring of the flame tube, the rear section 5 of the inner ring of the flame tube and the rear mounting edge 6 of the inner ring of the flame tube as the inner wall component 16, and then perform the first heat treatment;

[0047] S2. Use the front wall component welding jig 9 to assemble and weld the front wall 1 of the flame tube and the front section 2 of the inner ring of the flame tube to form the front wall component 15, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com