Technique for integrally manufacturing semi-structure of full-face tunneling machine shield

A technology of full-face boring machine and process method, which is applied in the direction of manufacturing tools, metal processing equipment, welding equipment, etc., and can solve problems such as easy deformation of welding, difficulty in half-body joining, and difficulty in ensuring tolerances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

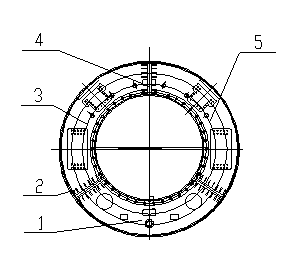

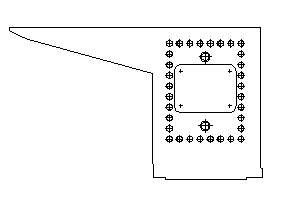

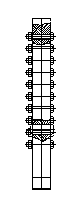

[0011] Referring to the accompanying drawings, it is a process method for integrally manufacturing the shield body of a full-face roadheader in half. The front shield body is divided into three parts: the left half body 3, the right half body 5, and the lower half body 1. Process the connecting flange 4 and then use the process bolts to connect each pair of flanges, and weld them as an assembly with each half body; when the overall heat treatment is performed, in order to prevent the flange surface from being disengaged and produce slot deformation, the inner shell plate is connected At the seam, the welded dense steel plate tie bars 2 are connected. After heat treatment, the steel plate tie bars 2 are cut off according to the processing conditions, and polished and repaired; The bolts combine the two flanges into one, and weld them with the steel plate on the shield body as an assembly to solve the problems of easy deformation of welding, difficulty in processing flanges, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com