Connecting structure and installation method for piston and piston rod

A technology of connection structure and installation method, applied in the direction of piston rod, piston, piston ring, etc., can solve the problems of high processing technology requirements, piston shifting, easy desoldering, etc., to solve the problem of easy deformation and desoldering, and enhance locking The effect of fixing force and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

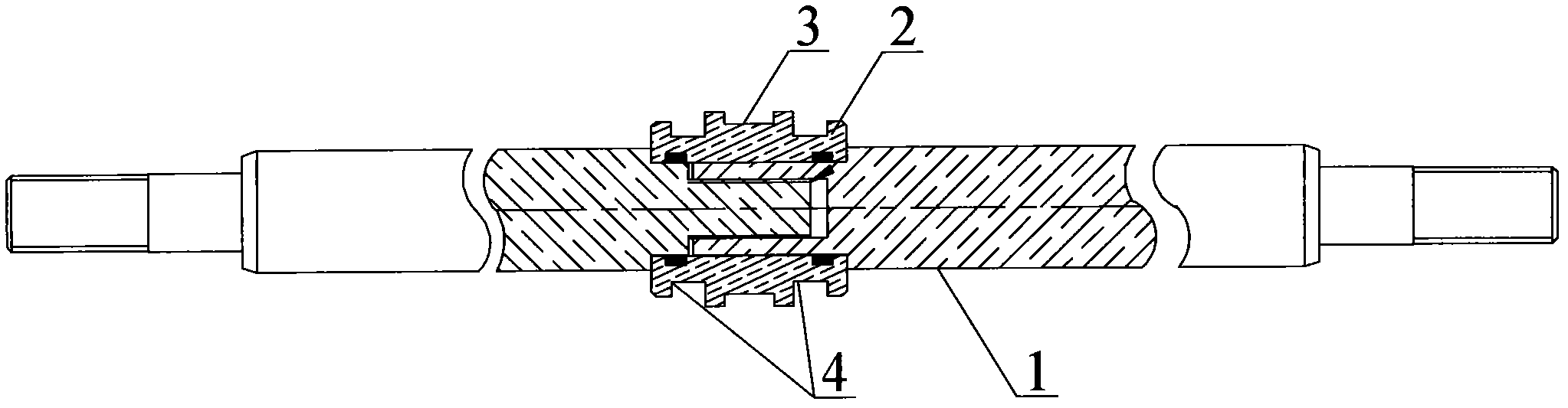

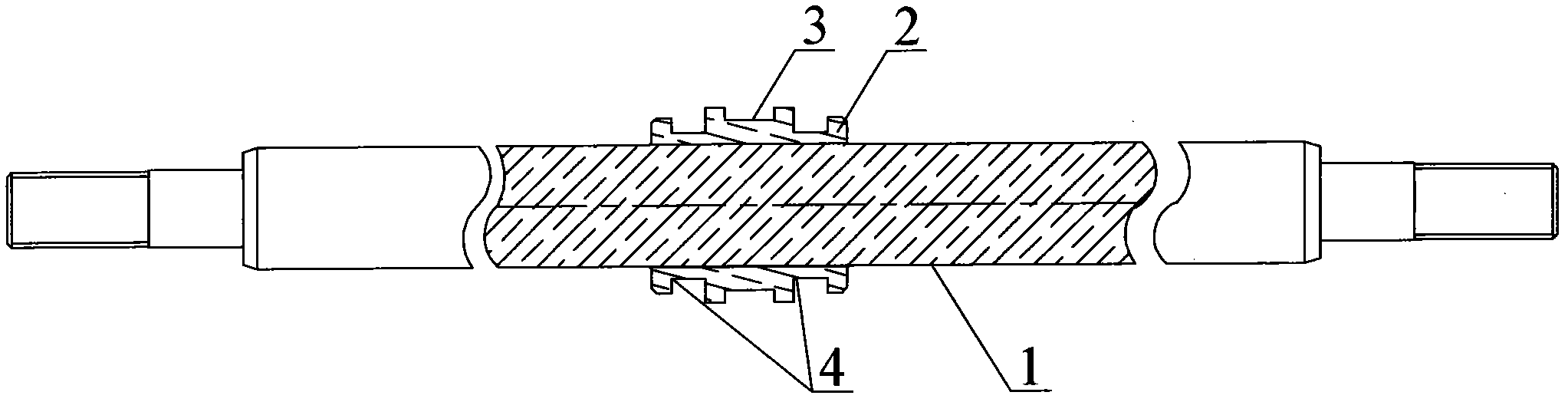

Embodiment 1

[0043] Such as image 3 As shown, the connection structure between the piston rod 1 and the piston 2 is: the piston 2 is directly sleeved on the piston rod 1, and the piston 2 and the piston rod 1 are in an interference connection, and there is no seal between the piston 2 and the piston rod 1 Under the premise of the ring, it can also achieve a tight sealing and locking state. The outer wall of the piston 2 is also provided with a wear-resistant pad slot 3 and a sealing ring slot 4. The number of the wear-resistant pad slot 3 and the sealing ring slot 4 is more than one, and the wear-resistant pad slot 3 is installed Wear-resistant pad, because the overall structure of piston 2 and piston rod 1 is sliding in the oil rod, the outer side of piston 2 will rub against the inner wall of the oil rod, thereby causing wear to the outer wall of piston 2 and the oil rod, after installing the wear-resistant pad Will reduce the wearing and tearing to piston 2 and oil rod, and get final ...

Embodiment 2

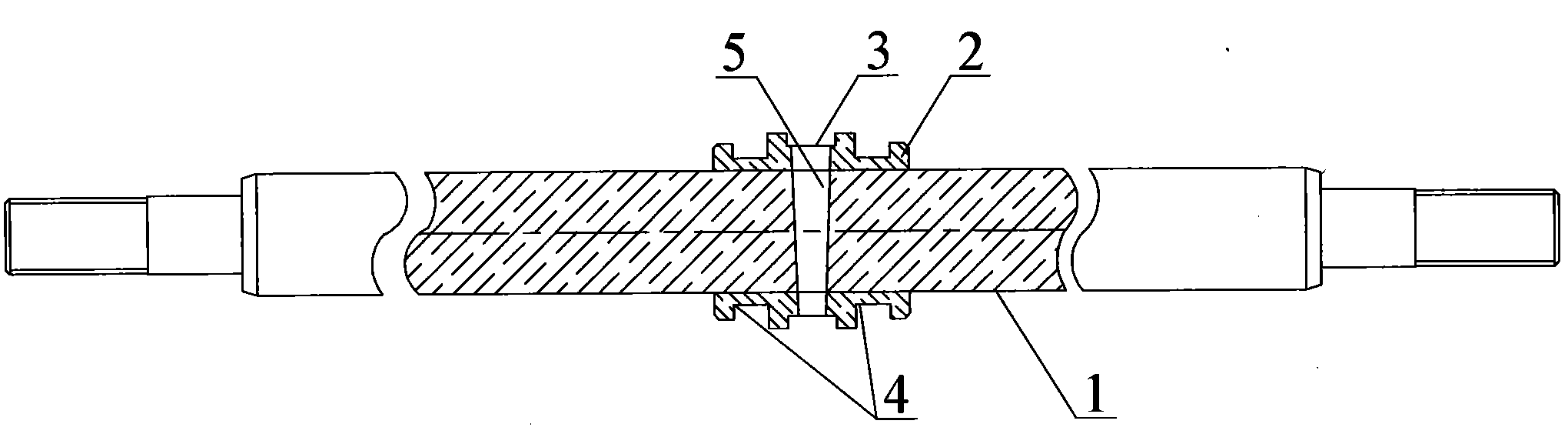

[0052]The only difference from Example 1 is that the piston 2 is also provided with a tapered pin hole 5 passing through the piston rod 1 from one side to the other side, and the tapered pin hole 5 is located on the wear-resistant pad in slot 3. Since the wear-resistant pad groove 3 is located in the middle of the piston 2 , the taper pin hole 5 is also located in the middle of the piston 2 . The main function of the taper pin hole 5 is to install the taper pin, thereby enhancing the locking force of the piston. Whether the taper pin hole 5 is set or not is determined according to the actual situation, and the number of settings is also determined according to the actual situation. In this embodiment, the number of the taper pin hole 5 is more than one, and it is set around the central axis of the piston rod 1, and the central axis It may not intersect with the central axis of the piston rod 1, but in order to enhance the locking effect, in general, the central axes of the ta...

Embodiment 3

[0055] The difference with Embodiment 2 is only that: when the width of the wear-resistant pad slot 3 is small, all the tapered pin holes 5 can only be arranged on the same circumference, that is, the central axes of all the tapered pin holes 5 must be in the same plane. A problem that exists at this moment is exactly: if all taper pin holes 5 are processed at one time, because the central axes of all taper pin holes 5 all intersect and have only one intersection point, this intersection point is exactly each taper pin hole 5 central axes and the piston. The intersection point of the central axis of the rod 1 is defined as the center point. After installing a taper pin, this center point is occupied, so that other taper pins cannot be installed.

[0056] The structure of the above-mentioned taper pin 5 requires its processing steps as follows: (a) drill a taper pin hole 5 in the wear-resistant pad groove (3) of the piston 2, and its axis is in a plane perpendicular to the cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com