Nickel-metal hydride battery shell electron beam welding method

An electron beam welding, hydrogen-nickel battery technology, applied in electron beam welding equipment, high-frequency current welding equipment, welding equipment and other directions, can solve the problems of welding deformation, high porosity, etc., achieve high welding yield, improve comprehensive mechanical performance, the effect of avoiding welding distortion problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

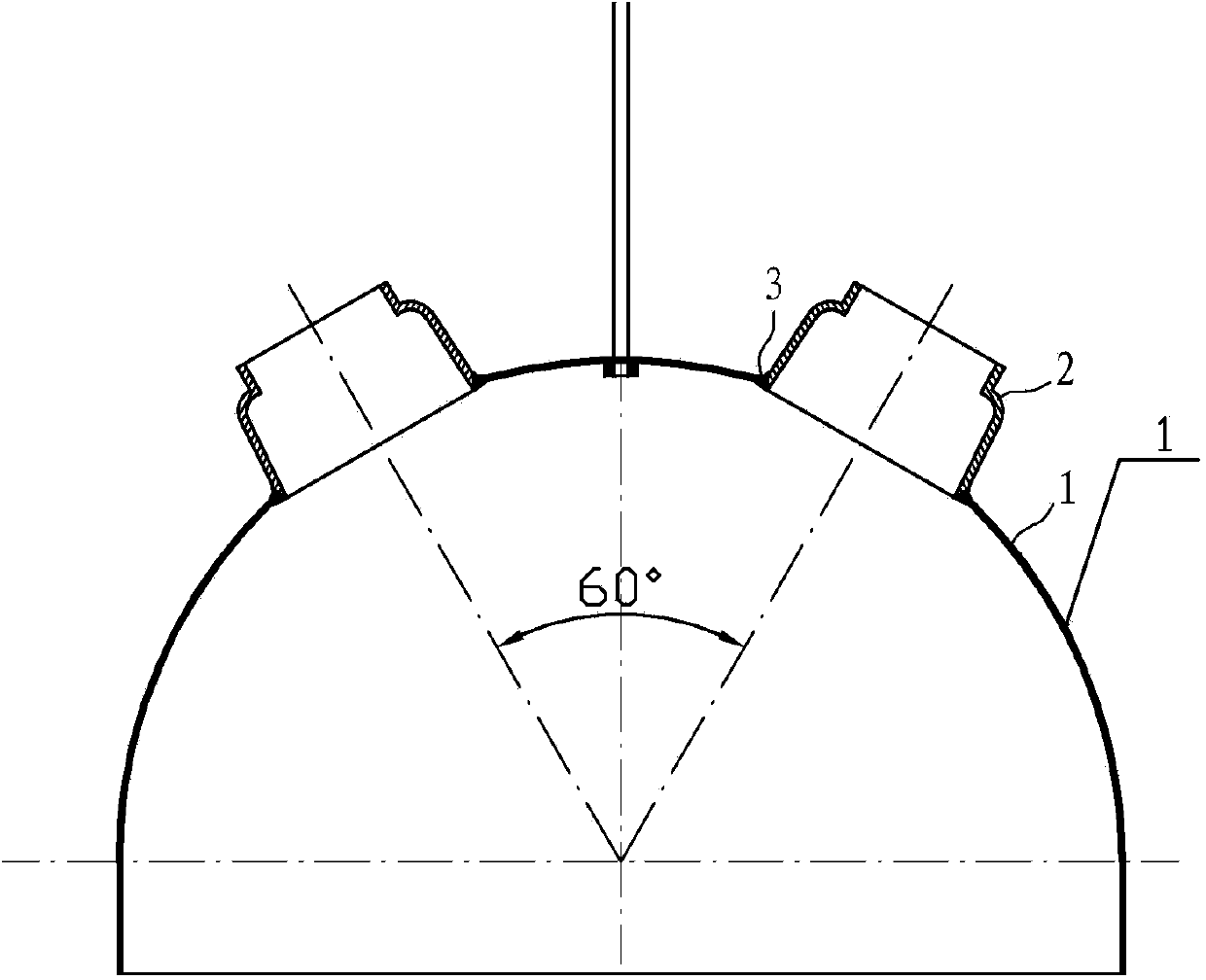

[0024] Example 1, a batch of 20 initial samples of type I battery casings were welded, and the penetration depth of the welds was 1.1 mm.

[0025] Preparations before welding: First, use clean white gauze dipped in acetone to clean the upper shell and the pole sleeve respectively. The cleanliness of the surface to be welded requires no oil film, water film and other organic impurities on the welded surface. It is also forbidden to touch and re-contaminate by hand. Once the workpiece is cleaned, it should be welded as soon as possible, and clean white gloves should be worn when cleaning. After cleaning, assemble the pole sleeve and the upper case. The assembly adopts special tooling fixtures, and the assembly gap is less than 0.05mm

[0026] A 60kV medium-voltage numerical control electron beam welding machine is adopted, and its main welding process parameters are as follows: acceleration voltage is 59.5kV, welding beam current is 3.5mA, surface focusing is selected, focusing ...

Embodiment 2

[0029] Example 2, a batch of 20 primary products of Type II battery shells were welded, and the penetration depth of the welds was 1.1 mm.

[0030] Preparation before welding refers to Example 1, using a 60kV medium-voltage numerical control electron beam welding machine, and its main welding process parameters are as follows: the acceleration voltage is 60.5kV, the welding beam current is 3.7mA, surface focusing is selected, the focusing current is 3.00A, and the welding speed It is 500mm / min, and the welding vacuum is 4.5×10-4mbar.

[0031] Appearance inspection and X-ray inspection are carried out on product welds, and the pass rate is 100%.

Embodiment 3

[0032] In Example 3, a batch of 20 initial products of Type II battery shells were welded, and the penetration depth of the welds was 1.1 mm.

[0033] Preparation before welding refers to Example 1, using a 60kV medium-voltage numerically controlled electron beam welding machine, and its main welding process parameters are as follows: the acceleration voltage is 60.0kV, the welding beam current is 3.9mA, surface focusing is selected, the focusing current is 2.98A, and the welding speed It is 500mm / min, and the welding vacuum is 4.5×10-4mbar.

[0034] Appearance inspection and X-ray inspection are carried out on product welds, and the pass rate is 100%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com