Combined tool for manufacturing manifolds

A technology of tooling and manifolds, applied in the direction of manufacturing tools, auxiliary devices, metal processing equipment, etc., can solve problems such as welding deformation, achieve the effect of reducing welding deformation, solving welding deformation, and improving construction accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

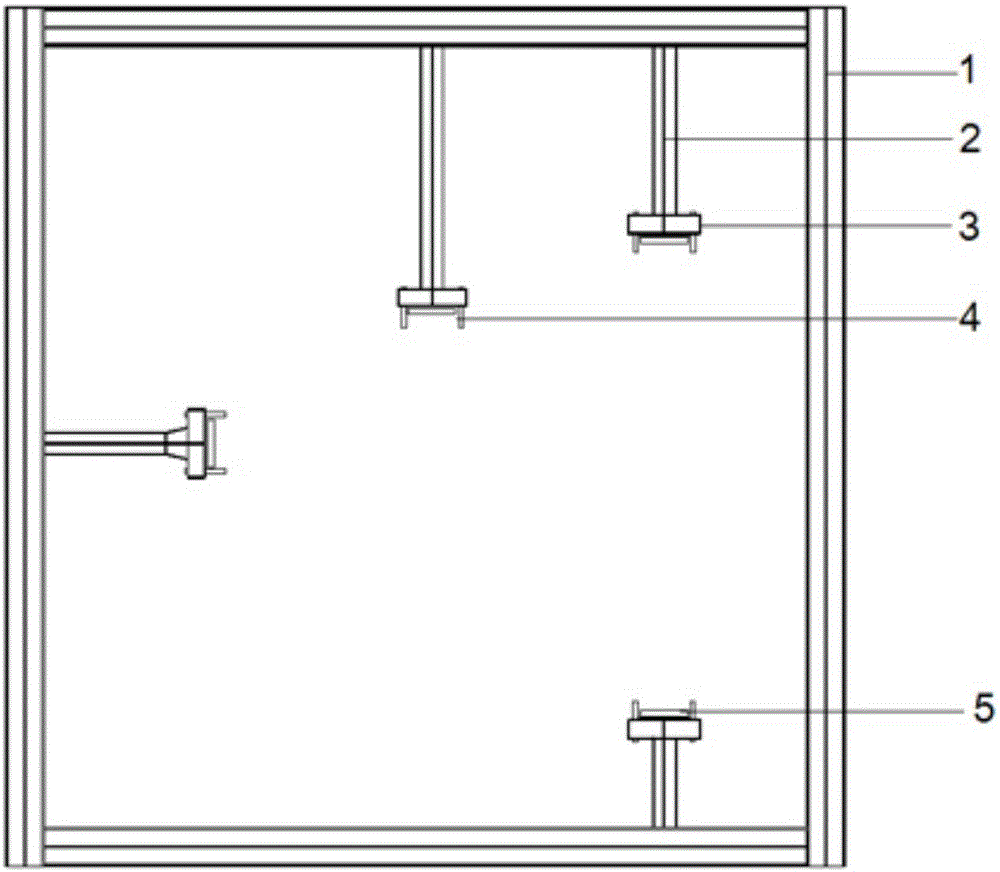

[0021] Such as figure 1 As shown, the present invention includes: prefabricated tooling and two parts of assembly tooling used in conjunction with the prefabricated tooling, wherein the prefabricated tooling is provided with: an external support frame 1, several pieces fixed on the external support frame 1 by bolts or welding The internal support 2 is respectively fixed on the internal support 2 by bolts or welding, and the limit joint 3 that constrains the branch of the manifold; the fixed space between the several limit joints 3 ensures that all branch pipes as a whole The prefabricated dimensions are consistent and meet the tolerance requirements of the drawings;

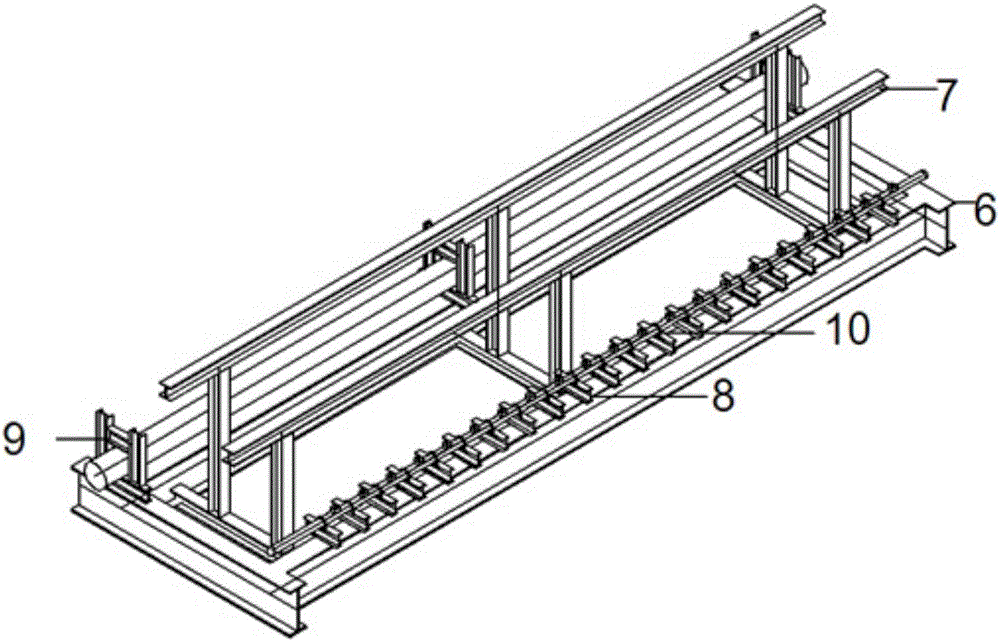

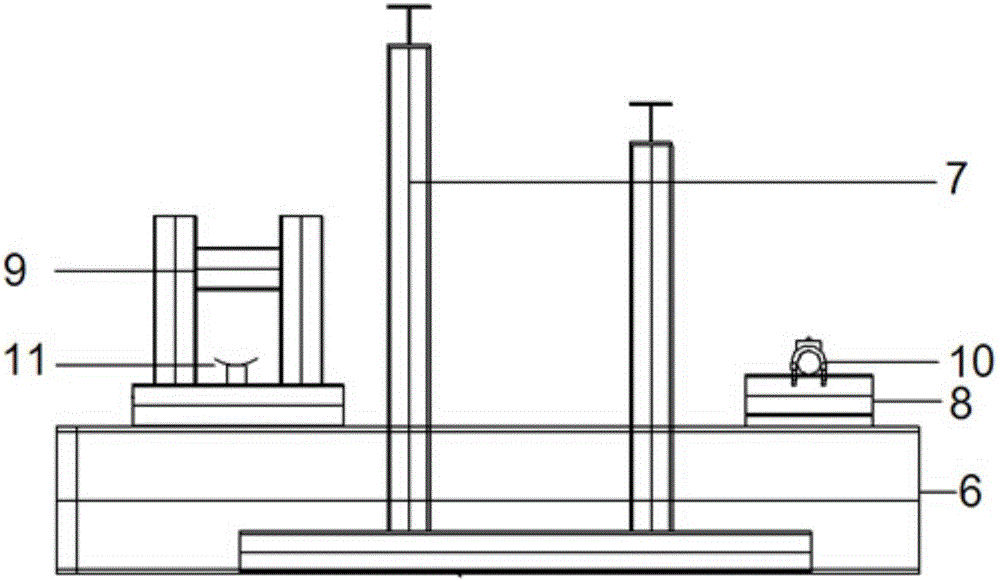

[0022] The assembly tool is provided with: a base frame 6, two branch pipe support beams 7 installed oppositely and vertically on the base frame 6, several main pipe support beams 8 uniformly fixed on both sides of the base frame 6, fixed on the base frame 6- The female pipe limiting frame 9 on the side, several...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com