Welding process of low temperature steel welding body case

A welding process and low-temperature steel technology, applied in the direction of welding medium, welding equipment, welding equipment, etc., can solve the problems of welding deformation and welding efficiency, and achieve the effect of solving welding deformation, ensuring welding quality, and narrow heat-affected zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is described in further detail below in conjunction with the example of implementation.

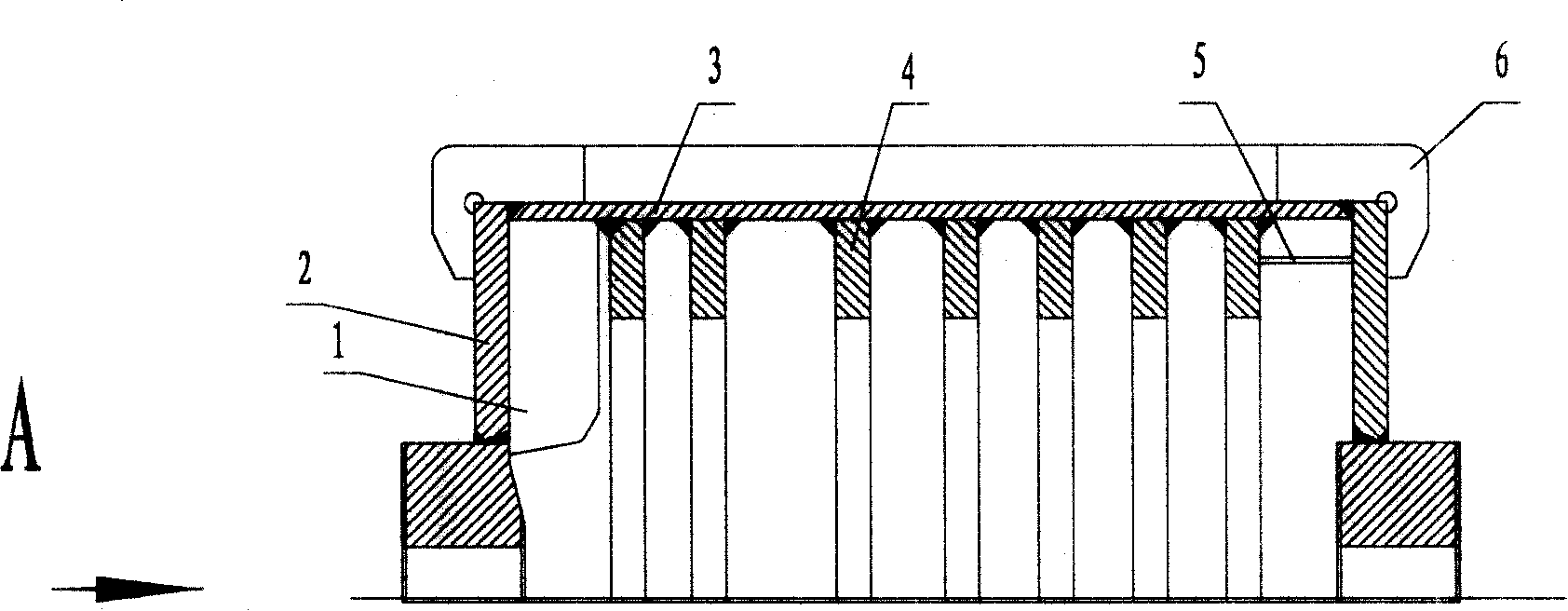

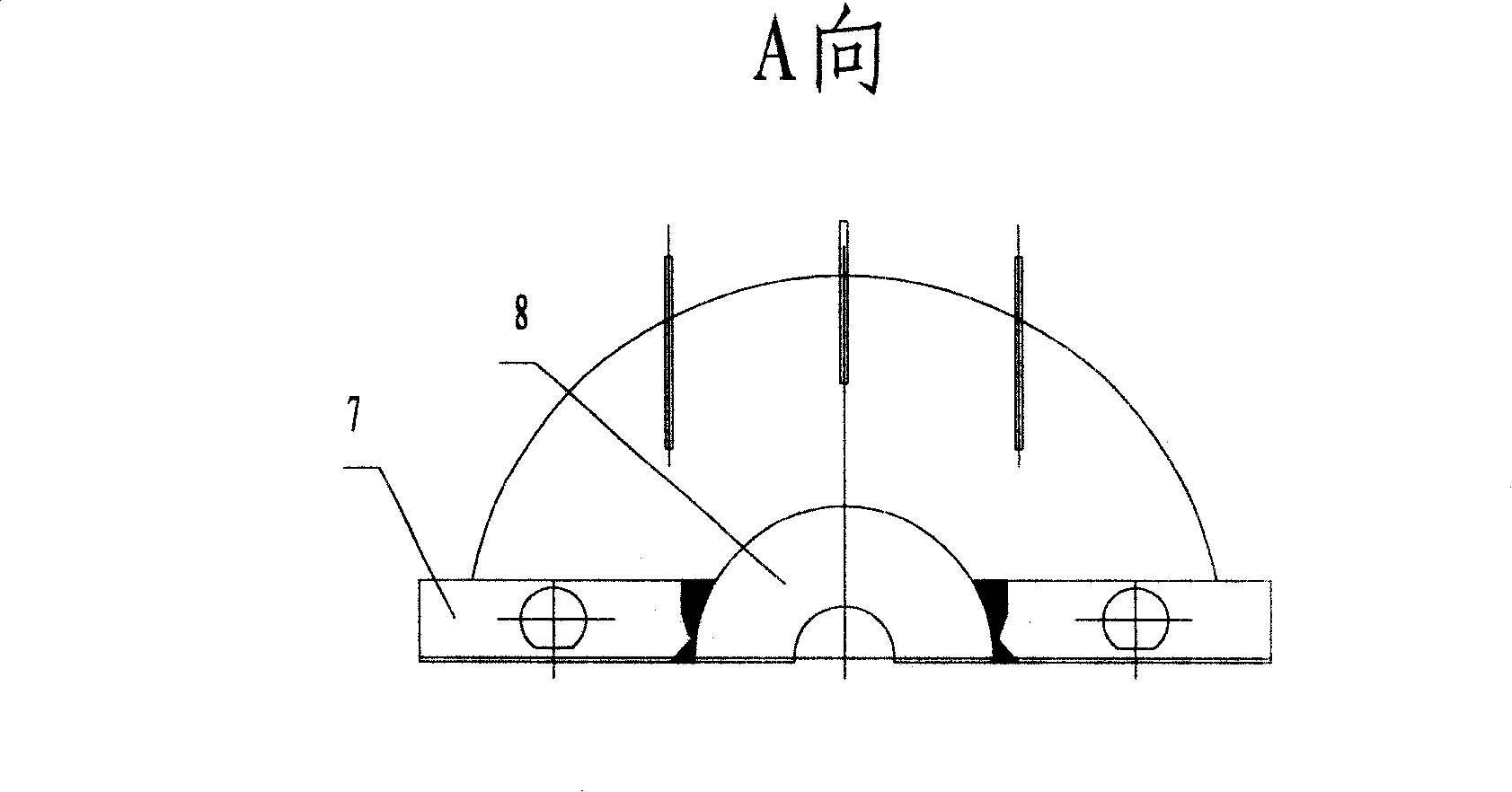

[0043] 1. Structural design of welded casing

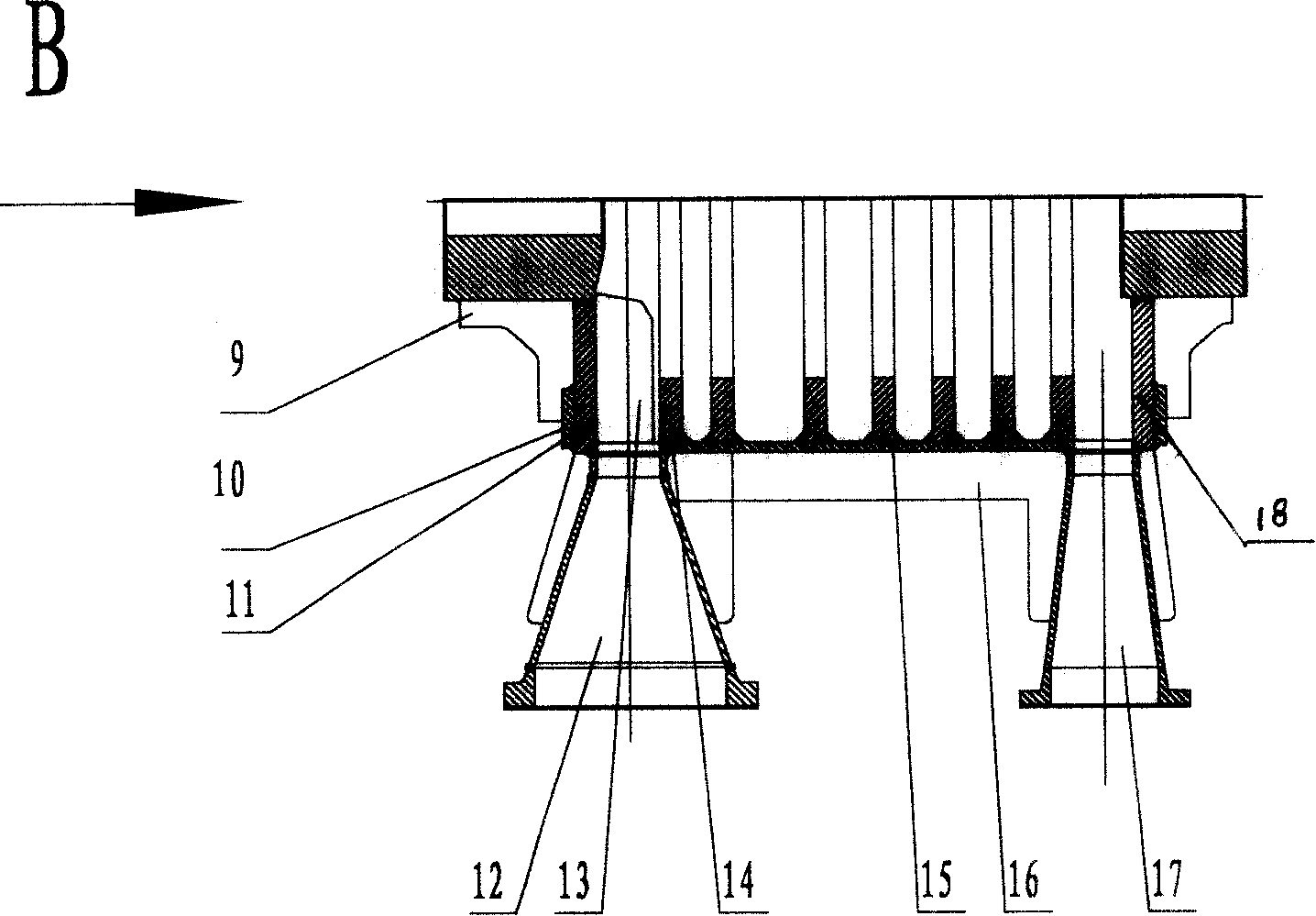

[0044] The welded casing of the compressor is composed of an upper casing and a lower casing, both of which are of welded structure. The MCL807 upper case consists of the upper case flange 7, the upper case sealing body 8, the upper case shell plate 3, the upper case end plate 2, the upper case support ring 4, the upper case diverter plate 1, the upper case The casing volute chamber baffle plate 5, the upper casing rib plate 6 and other components, the thickness of the upper flange is 140-250mm, the thinnest plate in the casing is 40mm, and the weight of the upper casing is 13.5 tons. Figure 1a -b shown.

[0045] The lower casing consists of lower casing lower flange 19, lower casing sealing body 20, lower casing shell plate 15, lower casing end plate 18, lower casing support ring 14, lower casing splitter plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com