A spot welding machine hot air circulation system

A circulation system and spot welding machine technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of low product qualification rate, high energy consumption of equipment, unstable quality, etc., and achieve high thermal efficiency, Small fluctuations in soldering temperature and improved soldering reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

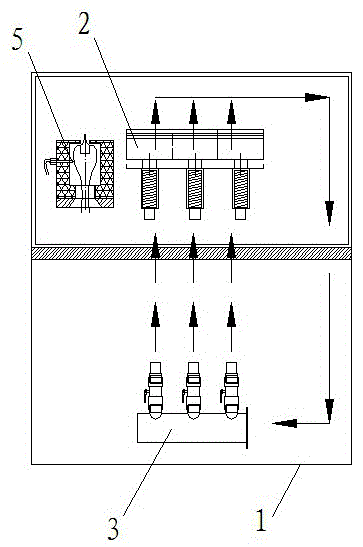

[0015] Such as figure 1 As shown, a spot welder hot air circulation system includes a welding box 1, a heating device 2 and a blower 3, the heating device 2 and the blower 3 are arranged in the welding box 1, the heating device 2 is arranged at the air outlet of the blower 3, and the blower 3 The air inlet is used to inhale the air in the welding box 1, and the door of the welding box 1 is provided with a sealing device for sealing the air in the welding box 1 box.

[0016] Since the sealing device of the welding box 1 strengthens the sealing of the box room, and at the same time, the air inlet of the blower 3 sucks the hot air in the box room, and then blows the hot air out from the air outlet, and passes through the heating device 2, so that the hot air in the box room can be circulated use. Hot air circulation is even and efficient. The air source is driven by the circulation blower 3 to drive the wind wheel through the heating device 2, and the hot air is sent out, and t...

Embodiment 2

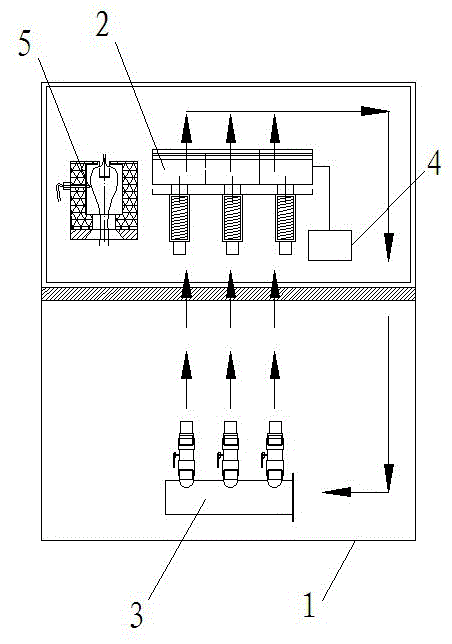

[0018] Such as figure 2 As shown, the rest is the same as that of Embodiment 1, except that it also includes a temperature control device 4 for detecting the temperature in the welding box and automatically controlling the operation of the heating device 2 . The temperature control device 4 is set. After working for a period of time, the thermal energy in the chamber will be more or less lost. At this time, the welding temperature in the chamber does not meet the work requirements. The temperature control device 4 automatically controls the heating device 2 to work to meet the needs of the work. Compensate for the heat energy in the chamber.

[0019] The beneficial effects of adopting this technical solution are: high thermal efficiency, energy saving and environmental protection, and at the same time, small fluctuations in welding temperature, effectively ensuring product quality stability, shortening welding cycle, and improving welding reliability.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com