Welding tool frame for carbon dioxide gas shielded welding and its welding method

A technology of gas shielded welding and welding method, which is applied in the direction of welding equipment, manufacturing tools, welding rod characteristics, etc., can solve the problems of difficult to guarantee welding quality, easily affected welding quality, and high labor intensity of operation, so as to shorten the welding cycle and improve the surface quality. Smooth forming and improved welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

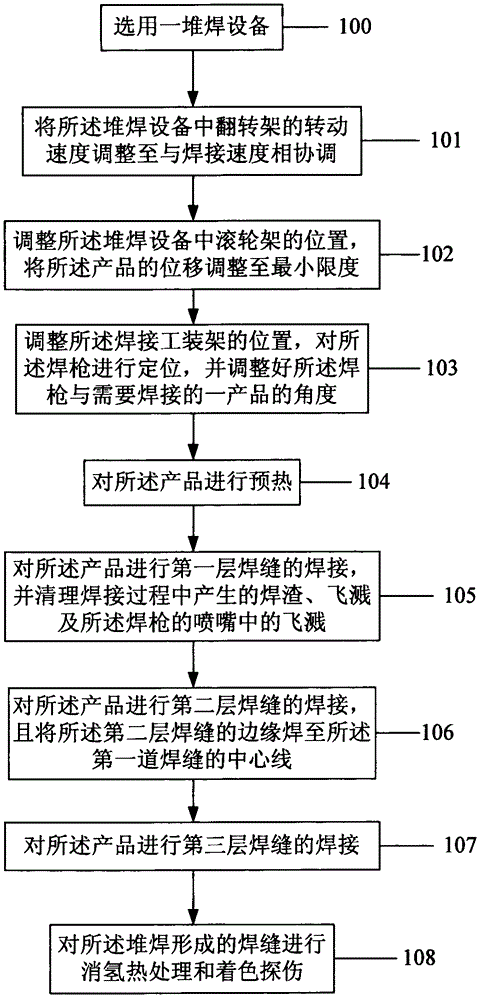

[0045] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

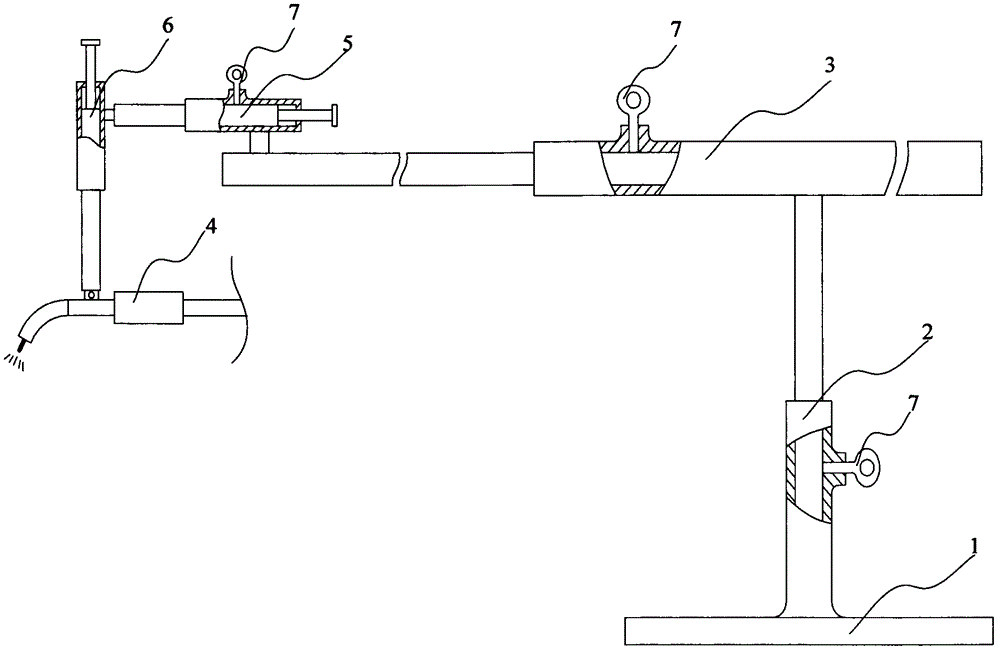

[0046] Such as figure 1 As shown, the welding tool frame for carbon dioxide gas shielded welding of the present invention includes: a base 1 and an adjustment device, and the adjustment device is mainly used to adjust the position of a welding torch 4 . One end of the entire adjusting device is fixed on the base 1 , while the other end is connected to the welding torch 4 .

[0047] Wherein, preferably, the adjustment device includes an up and down coarse adjustment part 2 and a front and rear coarse adjustment part 3 . The upper and lower coarse adjustment parts 2 are fixed vertically on the base 1 , and the front and rear coarse adjustment parts 3 are fixed on the upper end of the upper and lower coarse adjustment parts 2 horizontally.

[0048]Further, the adjustment device may also i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com