Patents

Literature

56results about How to "No sanding required" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

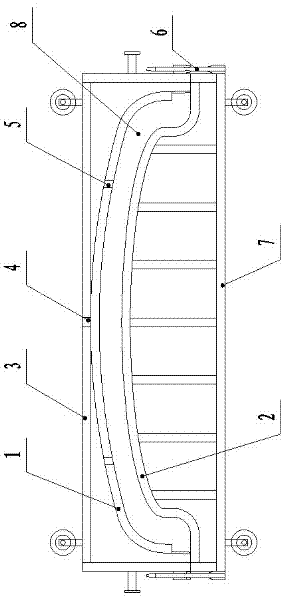

Magnetostrictive guided-wave sensor for detection in heat exchange tube and detection method thereof

InactiveCN102520057ALow surface conditionNo sanding requiredMaterial magnetic variablesElectricityEngineering

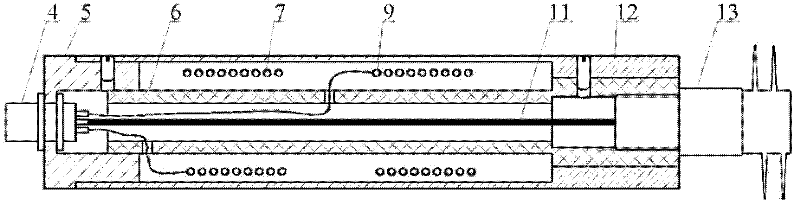

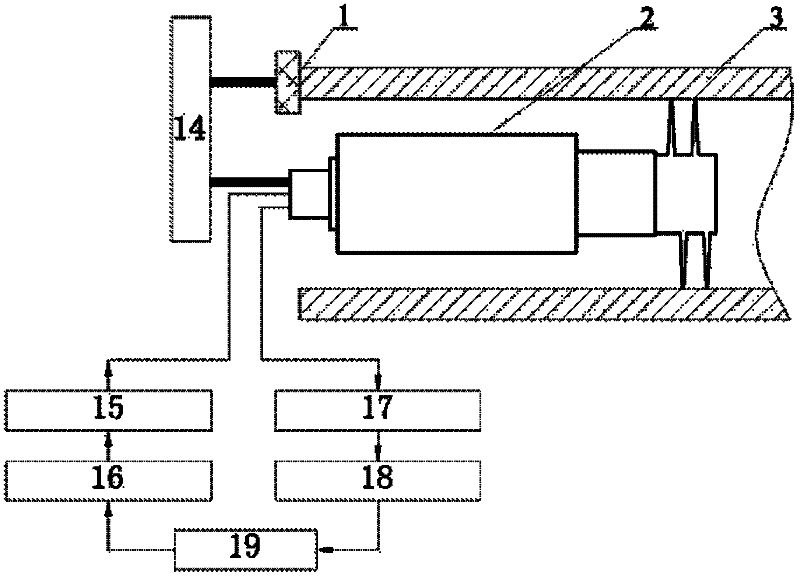

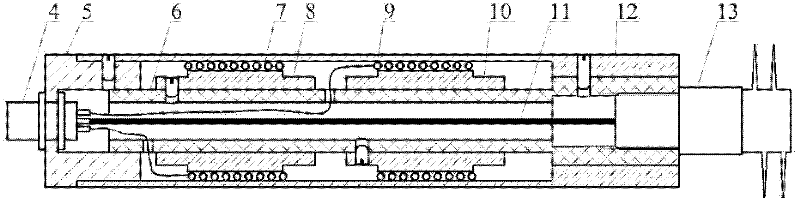

The invention discloses a magnetostrictive guided-wave sensor for the detection in a heat exchange tube and a detection method thereof. The sensor comprises a shell, an end cover fixed with one end of the shell, a conductive steel brush connected with the other side of the shell, an inner shell which is arranged in the shell and connected with the shell, an aerial socket which is arranged on the end cover and electronically connected with the conductive steel brush through direct current leads of the inner shell, a first magnetic concentrator and a second magnetic concentrator which are respectively arranged at different positions of the inner shell, and a first alternating current coil and a second alternating current coil which are respectively winded along the first magnetic concentrator and the second magnetic concentrator and are respectively electronically connected with the aerial socket. According to the invention, the whole detection process is realized by magnetic field, belonging a non-contact detection, thus the requirement of the surface conditions in the heat exchange tube to be detected is low, polishing and other special treatment are not needed, and the detection efficiency and applicability are raised.

Owner:HUAZHONG UNIV OF SCI & TECH

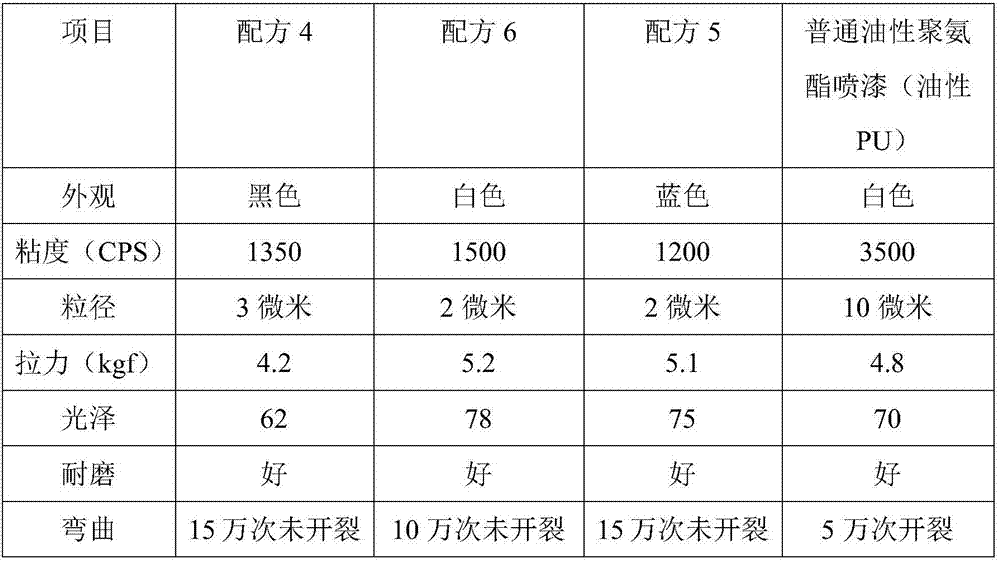

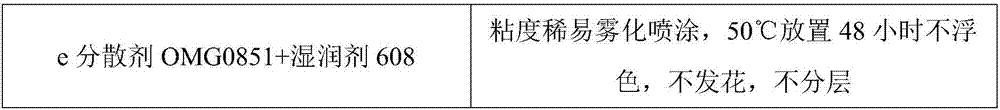

Waterborne polyurethane spray paint for fabric and shoe materials and preparation method of waterborne polyurethane spray paint

InactiveCN107418418AGood dispersionLow viscosityPolyurea/polyurethane coatingsEmulsion paintsDispersion stabilityBiological activation

The invention discloses waterborne polyurethane spray paint for fabric and shoe materials and a preparation method of the waterborne polyurethane spray paint. The waterborne polyurethane spray paint is prepared from components such as waterborne polyurethane, water, toner and auxiliaries. The spray paint is good in dispersion stability, high in dyeing degree, good in brilliance, easy to process, free of sagging, free of bubbles, good in levelling, physical property and activation property, easy for secondary processing and free of polishing, can be bent for 130 thousand times or more, and is especially suitable for materials such as the fabric and the shoe materials.

Owner:HUNAN XINLIHUA NANO TECH

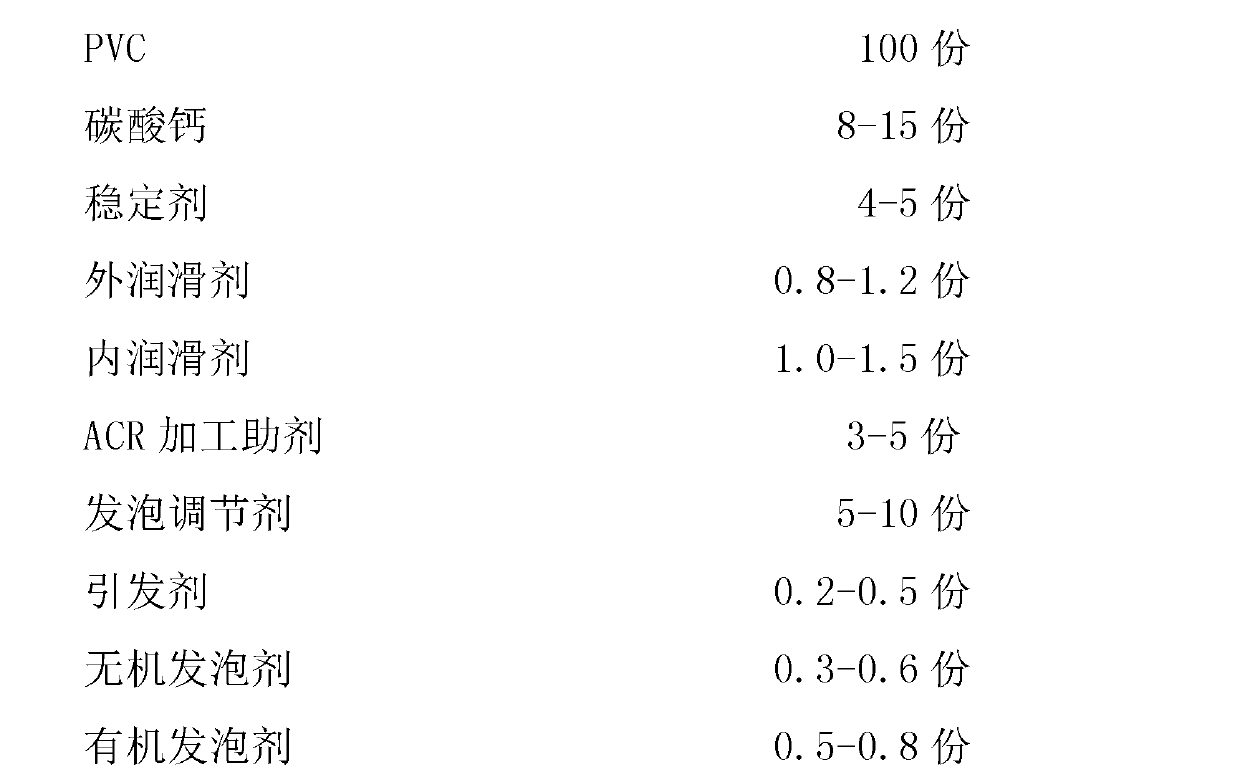

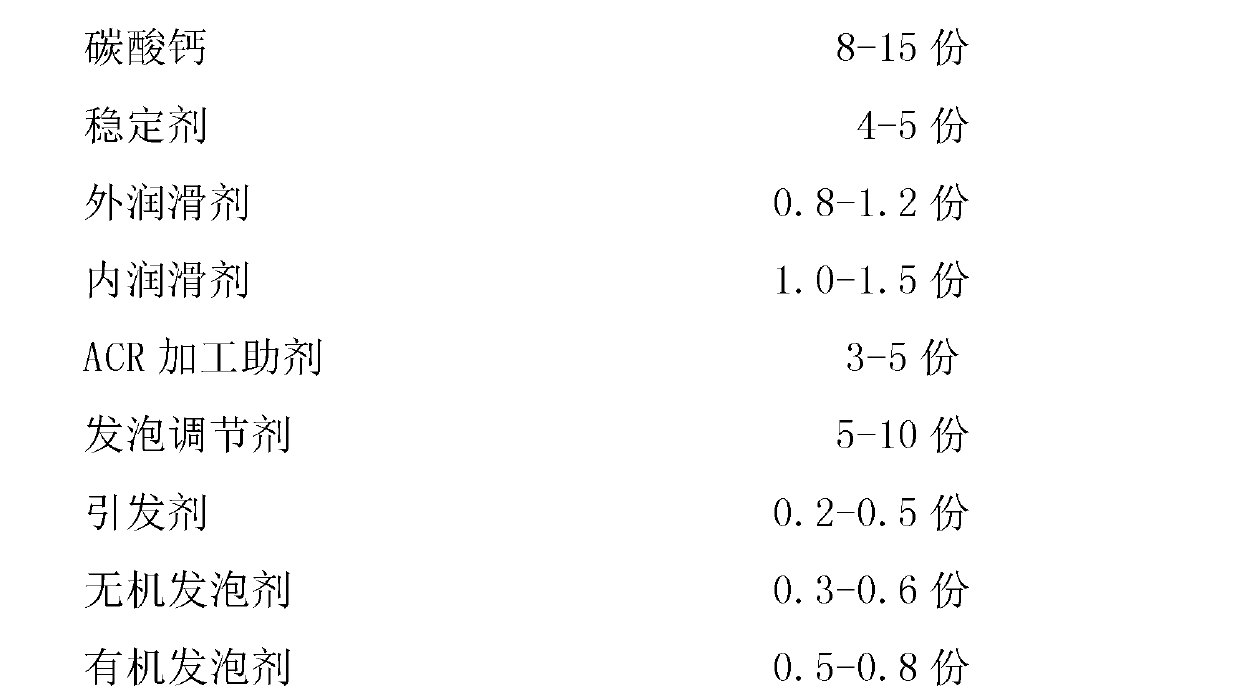

Formula of polyvinyl chloride (PVC) foamed sheet and preparation method thereof

The invention discloses a formula of polyvinyl chloride (PVC) foamed sheet and a preparation method thereof. The foamed sheet comprises the following components: 100 parts of PVC, 8-15 parts of calcium carbonate, 4-5 parts of stabilizer, 0.8-1.2 parts of external lubricant, 1.0-1.5 parts of internal lubricant, 3-5 parts of acrylics (ACR) processing agent, 5-10 parts of foaming modifier, 0.2-0.5 part of initiator, 0.3-0.6 part of inorganic foaming agent and 0.5-0.8 part of organic foaming agent. The invention also discloses the method for producing the PVC foaming sheet. The components are subjected to two processes of material mixing and extrusion forming and then the required sheet is produced. After the formula and the preparation method are adopted, the production operational cycle is prolonged, the production efficiency is obviously increased and the rejection rate is reduced. Meanwhile, the foaming effect is excellent and the surface of the sheet products is even and does not need to be polished. The long-standing problem of the contraction of similar products is resolved. The surface skinning hardness and the smoothness are high and the material performance is excellent. The foamed sheet can meet the use requirements of various industries of indoor door, furniture, decorative material, construction and the like.

Owner:WUHU CONCH NEW MATERIAL

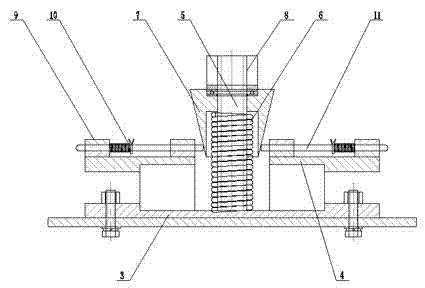

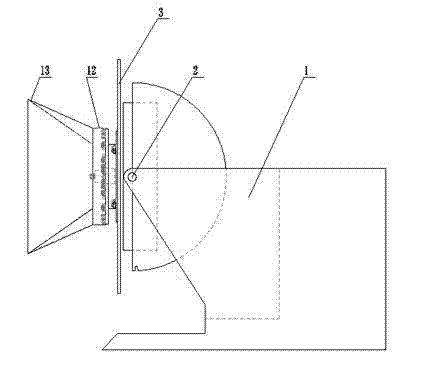

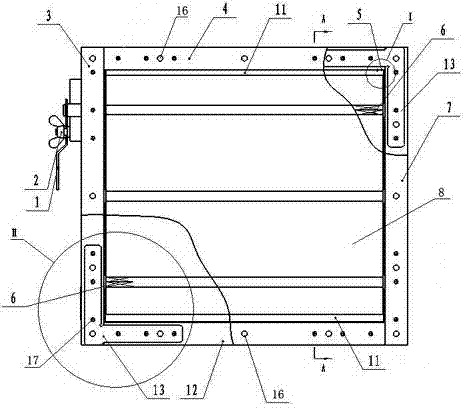

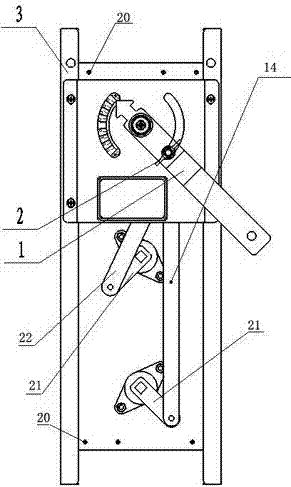

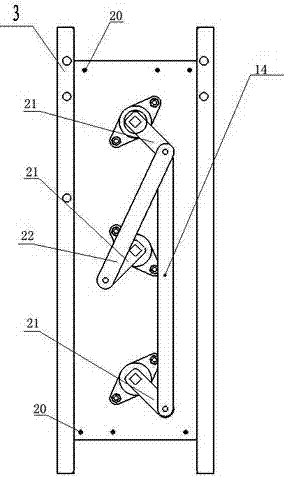

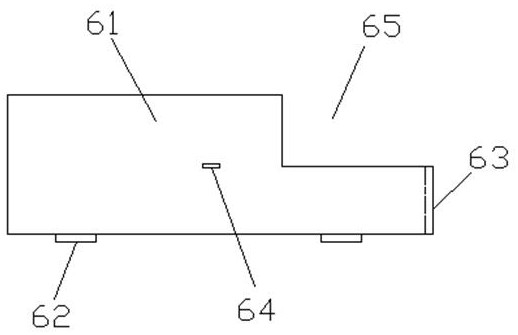

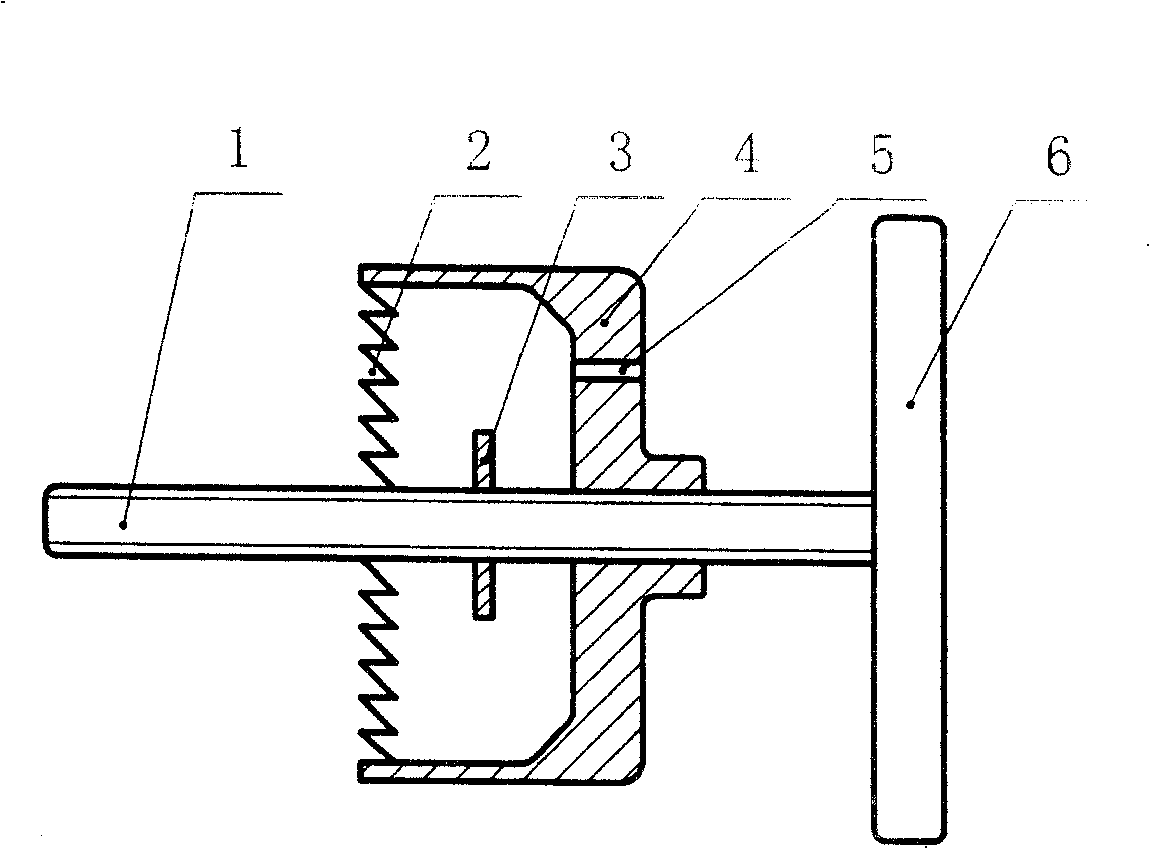

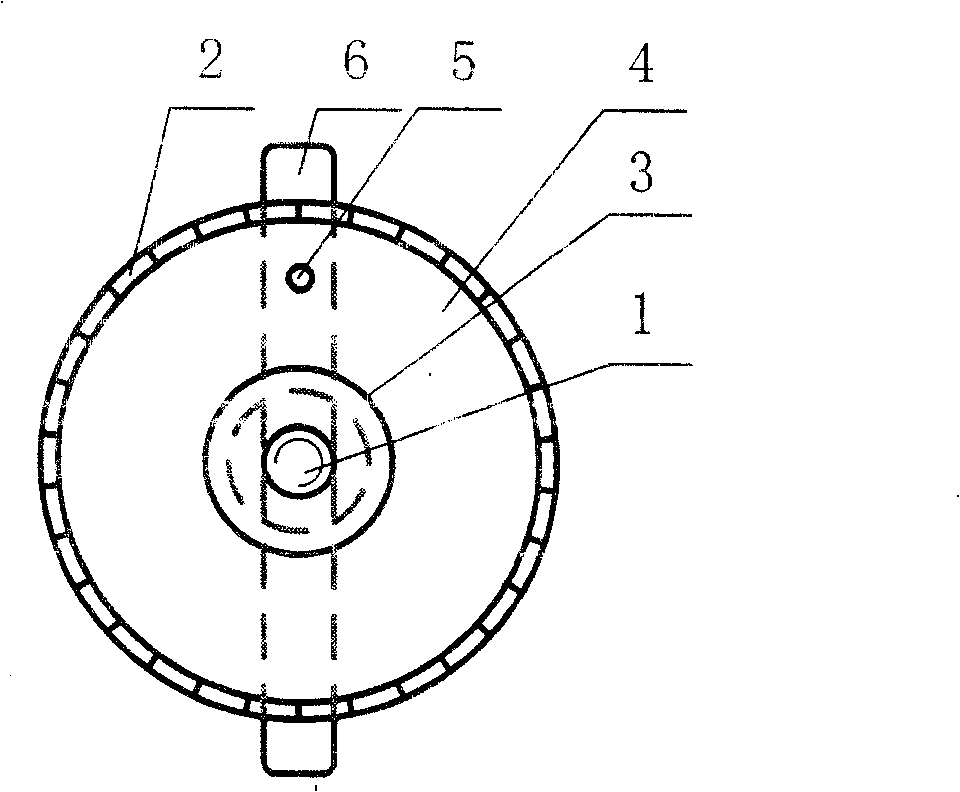

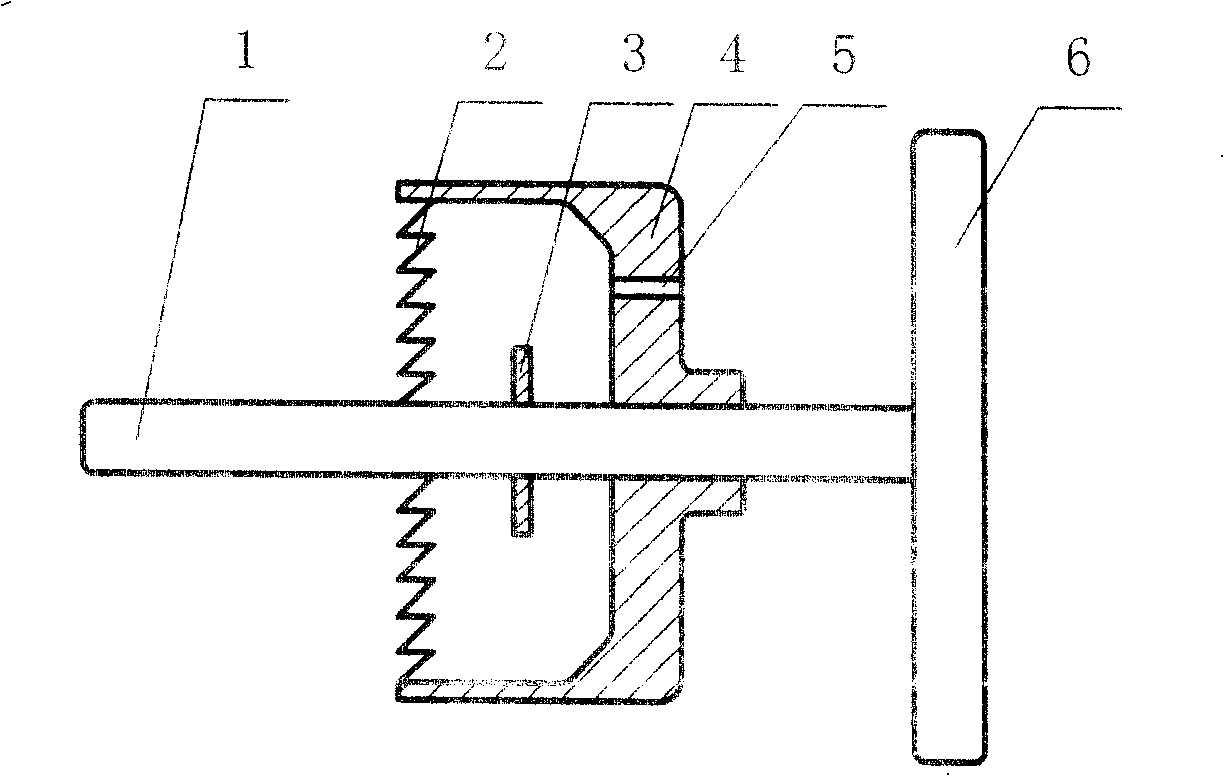

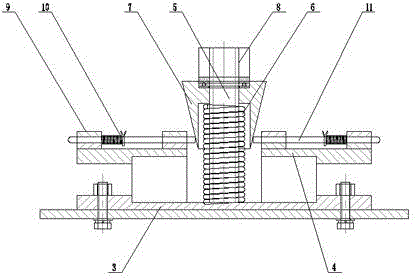

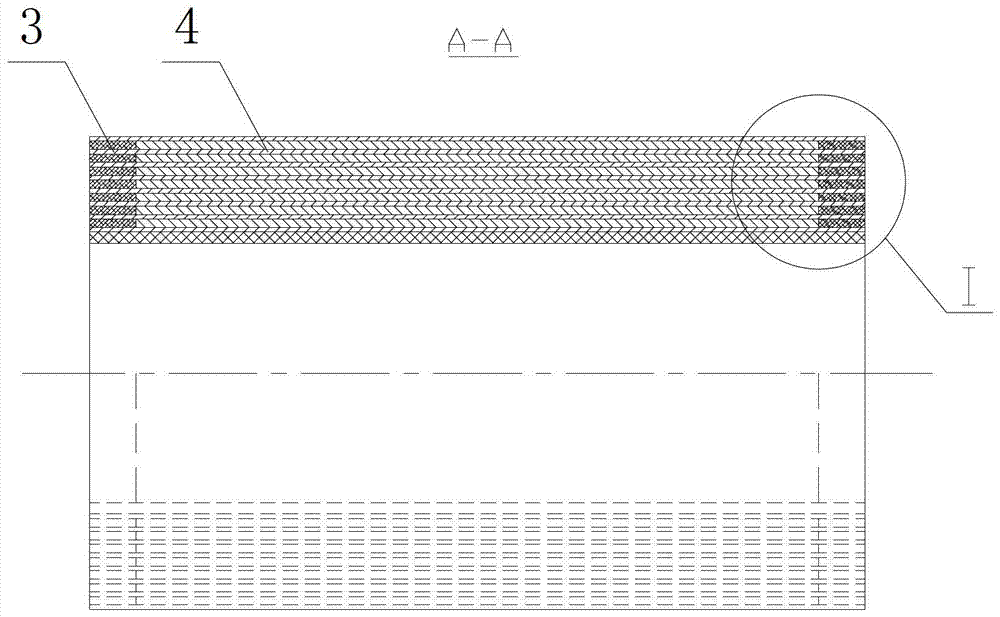

Bidirectional adjustable cylindrical welding anti-deformation fixture

ActiveCN102896455AAvoid welding deformationImprove molding qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention relates to a bidirectional adjustable cylindrical welding anti-deformation fixture which comprises a rotary table, a central compressing component and more than three groups of movable supporting components, wherein the central compressing component is arranged on the rotary table, the rotary table is in a rotation state around the central compressing component, the more than three groups of movable supporting components are uniformly distributed on the rotary table around the central compressing component, and the central compressing component props against the more than three groups of movable supporting components so that the movable supporting components are simultaneously extended outwards or simultaneously retracted. According to the bidirectional adjustable cylindrical welding anti-deformation fixture disclosed by the invention, the central compressing component drives the movable supporting components to prop against and fix a cylinder workpiece, and the rotary table capable of rotating in plane and space drives the cylinder workpiece to rotate in two directions by supporting the movable supporting components so that the cylinder workpiece is located and welded; in addition, the bidirectional adjustable cylindrical welding anti-deformation fixture disclosed by the invention has the advantages of simple structure, convenience in operation, low cost and good welding effect; and the welded workpiece has less possibility of deformation.

Owner:JIANGSU JOSUN SCI&TECH CO LTD

Stamping embedded hard sealing nuclear power air valve

The invention relates to a stamping embedded hard sealing nuclear power air valve which is technically characterized in that the front side and the rear side of an upper frame and a lower frame are respectively punched and embedded and connected with corresponding valve seats, the upper and the lower frames and a left and a right side frame are connected with internal angle iron through pulling rivets to form a valve body framework, eight corners of the valve frame are respectively punched and embedded and connected with corresponding connecting angle iron; and a valve plate comprises more than three blades and corresponding rotating shafts thereof, each blade is composed of a pair of symmetrical front and rear corrugated sheets and a pair of upper and lower elastic sheet sealing strips, the upper and the lower elastic sheet sealing strips are respectively clamped between upper and lower end parts of the front and the rear corrugated sheets, the front and the rear corrugated sheets are punched and embedded and connected, and the front and the rear corrugated sheets are punched and embedded and connected with the upper and the lower elastic sheet sealing strips. The invention has the advantage that the connection of the valve sheets does not generate stress and structure deformation and damage to the surfaces of the sheets.

Owner:SHIJIAZHUANG NO 1 VALVE FACTORY

Process for manufacturing reduction shell

InactiveCN102152073ANo sanding requiredHigh strengthGearboxesFoundry mouldsIntermediate frequencyHeavy load

The invention discloses a process for manufacturing a reduction shell. The process comprises the following steps of: A, manufacturing a precision aluminum die; B, injecting liquid paraffin at a certain temperature into the die through a paraffin injector so as to obtain a paraffin die; C, repeatedly performing coating and sand drenching on the paraffin die, and hardening the profiled shell and drying; D, dewaxing to obtain a cavity; E, roasting the profiled shell; F, smelting molten steel by using a middle-frequency sensing furnace; G, pouring the molten steel into the roasted profiled shell; H, removing the profiled shell, cutting away the casting head, clearing the sands and polishing so as to obtain a blank; I, performing corresponding thermal treatment on the blank; and J, machining the blank so as to obtain a high-precision product. By the adoption of a silicon sol precision steel casting technology, the appearance of a workpiece is flat and smooth, so polishing is not needed; and the reduction shell has high strength, plasticity and flexibility. The shortcomings that the products in the same type are easy to crack and cannot be repaired and the size precision cannot be guaranteed are basically overcome; therefore, trucks are safer and more stable and reliable under the condition of a heavy load.

Owner:林建昌

Method for preparing environmentally-friendly insect-preventing material

InactiveCN102187882AImprove protectionGood for permanent useBiocidePest repellentsEnvironmental resistanceBiotechnology

The invention provides a method for preparing an environmentally-friendly insect-preventing material and relates to a novel environmentally-friendly insect-preventing material based on plant composition and a preparation method thereof. The method comprises the following steps: rapidly drying and smashing fresh rhizomes, leaves, peels and seeds of a specific regenerating plant with a drug action, and preparing the dried and smashed substances according to a scientific ratio into a raw material; and integrating the raw material with other solidified materials by using a specific process and a slow-releasing technique, thus the active ingredients are released slowly and lastingly. The preparation process is simple and convenient, the raw material is easily available, the cost is low, the raw material can be industrially planted, and a novel occupation ideal of 'material farmer' is established. The insect-preventing material is safe to humans and animals, is ecologically environmentally-friendly and has a broad-spectrum parasite-expelling function, a long-acting drug action and an excellent effect. The insects hardly generate the resistance to drugs while the natural enemies of the insects are not hurt. By applying the environmentally-friendly insect-preventing material to the fields of agriculture and forestry, the damages to the living and growing capabilities of animals and plants caused by the plant diseases and insect pests are prevented, the environmentally-friendly organic food is produced, the environmental pollution problem caused by applying a large number of chemical pesticides is avoided, the food safety is strictly controlled from the source, the quality of agricultural products is increased, and the income of the famer is also increased.

Owner:卢红

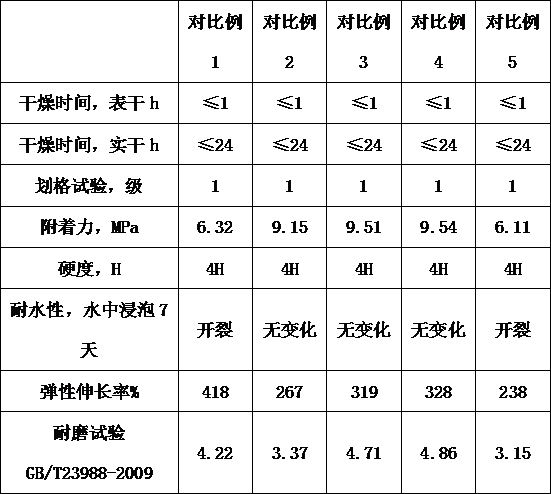

Free-of-polishing, double-component curable coating with super-strong adhesion and preparation method thereof

The present invention in particular relates to a free-of-polishing, double-component curable coating with super-strong adhesion which can be applied on any substrates of woodwares, and a preparation method thereof. The free-of-polishing polyurethane double-component curable coating with super-strong adhesion is prepared by mixing a finish, a curing agent and a diluent, and has good adhesion on substrates of woodwares; the polishing of the substrates is not required, thus producing no pollution to the environment and reducing labor costs; and the coating is a solvent free of benzene, which is more environmentally friendly, and has the flexibility matching the substrates.

Owner:SKSHU PAINT

Preparation process for thin ferrite sheet

ActiveCN106182374ANo sanding requiredHigh yieldCeramic shaping apparatusRejection rateMaterials science

The invention relates to the field of ferrite sheet preparation, in particular to a preparation process for a thin ferrite sheet. The preparation process comprises the following steps that (1) a ferrite raw material is pressed, a thick ferrite sheet is obtained, and the thickness of the thick ferrite sheet is 10-20 mm; and (2) the thick ferrite sheet obtained in the step (1) is subjected to sintering, slicing and washing. According to the preparation process for the thin ferrite sheet, the using amount of the raw material is decreased, the yield of the thin ferrite sheet and the efficiency are high, deformation is not prone to occurring, and the rejection rate is low.

Owner:滨海华源磁业有限公司

Method for making boomerang target based on target filament

The invention discloses a preparation method of the dart target based on the target wire, which collects the drawbench level polypropylene PP and the calcium bicarbonate as the raw materials, wherein the materials are mixed and fed to the belt packing machine and made into the tabletting-shape strip by the belt packing technics, then the strip is ripped into a plurality of target wires, and the strip is cut into the target wire, and through the target wire compression, the target wire levelness, the mould arrangement, the mould composition, the mould injection, the cooling, the mould disassembly and the like, the target and the target back (namely the motherboard) are formed into an integer. The target has the advantages of simple production, low production cost, no resilience of the made dart target, easy variegation of the dart target, level surface of the dart target without polishment, integral shape of the motherboard with the target wire without the stickiness.

Owner:聂晓庆

Novel nail polish

InactiveCN110638689AHigh glossFlat surfaceCosmetic preparationsToilet preparationsCyanoacrylatePolymer science

The invention discloses novel nail polish. The novel nail polish is prepared from colored gel, drier and seal gel, wherein the colored gel is prepared from the following components: a first cyanoacrylate monomer, a first thickening agent, a first polymerization inhibitor, toner, phosphate and anti-precipitation powder; the drier is prepared from a solvent and amine; and the seal gel is prepared from the following components: a second cyanoacrylate monomer, a second thickening agent and a second polymerization inhibitor. The novel nail polish has quick curing time, strong adhesion, simple operation steps, no dust pollution, no polishing and no lighting, can avoid hurt of light for eyes and human bodies, has high gloss and durable and bright colors, and has remarkable advantages than those of traditional solvent type nail polish, UV nail polish and dipping nail polish.

Owner:肇庆市宝骏化工有限公司

Finishing paint coating construction process of high-elasticity UV closed sheet having matte effect

InactiveCN107583838AImprove adhesionFast dryingPretreated surfacesGrinding machinesPuttyComposite material

The invention discloses a finishing paint coating construction process of a high-elasticity UV closed sheet having a matte effect. The finishing paint coating construction process comprises the following steps that the sheet is treated, high-elasticity UV putty is coated in a rolling mode, and the coating amount is 25-30 g / m<2>; a high-elasticity UV primer is coated in a rolling mode, and the coating amount is 60-70 g / m<2>; a high-elasticity UV sanding primer is coated in a rolling mode, and the coating amount is 25-30 g / m<2>; sanding and dust removal treatment is performed; a high-elasticityUV matte surface is coated in a rolling mode, and the coating amount is 25-30 g / m<2>; bending treatment is performed; a protective film is attached, and detection and package are performed. Accordingto the finishing paint coating construction process of the high-elasticity UV closed sheet having the matte effect, the sheet is firstly subjected to coating of the high-elasticity putty, the high-elasticity primer and the sanding primer and then coating of the high-elasticity UV matte surface in the rolling mode, the primer is ground, and then bending is performed, so that an obtained paint filmis uniform and flat in coating, the thickness of the paint film is greatly improved, the problems of crocodile skin and cracking are not likely to occur, and an attachment force is strong.

Owner:惠州市摩彩装饰材料有限公司

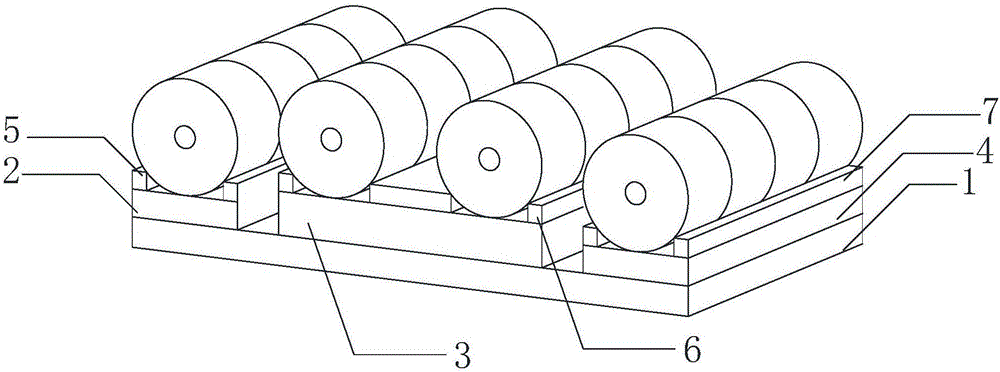

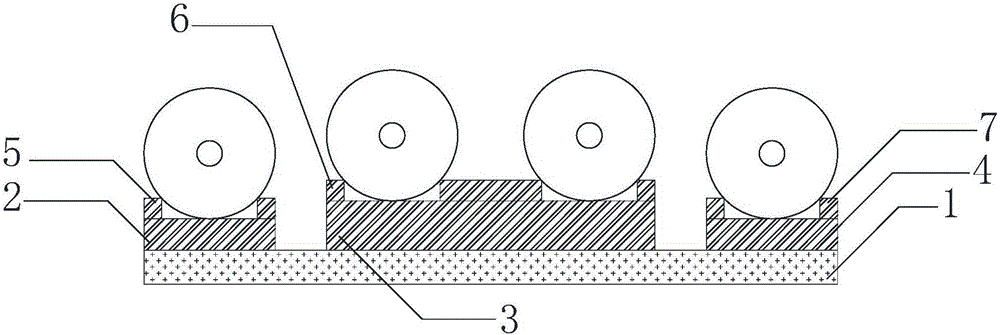

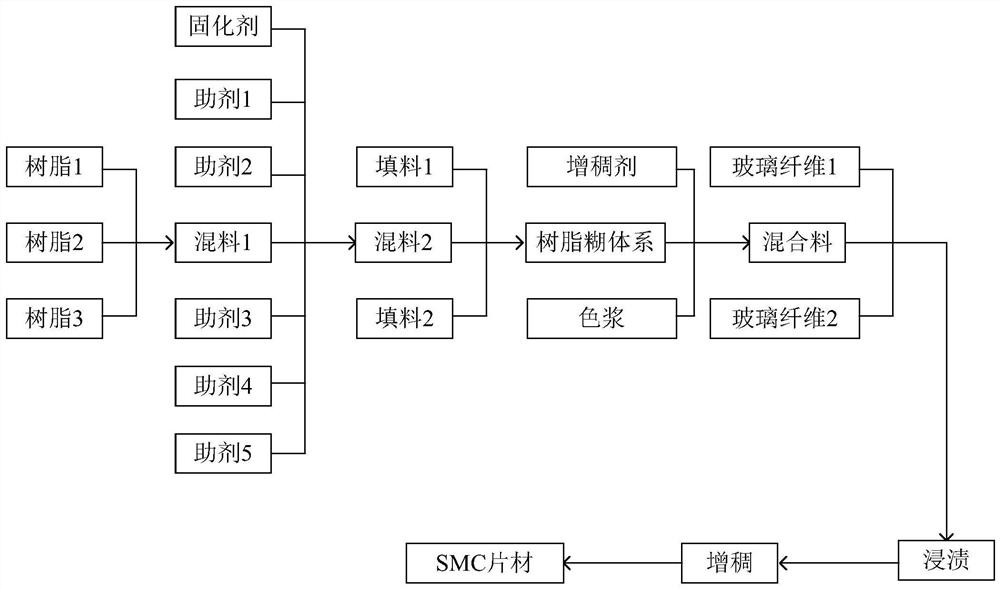

SMC composite material and preparation method thereof

The invention provides an SMC composite material which comprises the following components in parts by mass: 350 parts of mixed resin, 432 parts of a mixed additive, 650 parts of mixed filler, 8 parts of a thickener, 5 parts of a curing agent and 360 parts of a reinforcing material, wherein the mixed resin is a mixture calculated according to the following parts by mass: 200 parts of unsaturated polyester resin, 90 parts of modified methyl methacrylate and 50 parts of polystyrene; the mixed additive is a mixture which is prepared from the following components in parts by mass: 6.5 parts of a solvent-free wetting dispersant, 10 parts of a wetting dispersant, 15 parts of a release agent, 0.5 part of p-benzoquinone and 400 parts of an ultraviolet light absorber; the mixed filler is a mixture which is prepared from the following components in parts by mass: 400 parts of aluminum hydroxide and 250 parts of calcium carbonate. The SMC sheet prepared by the method can be directly sprayed with paint or bonded and compounded without polishing when being used for producing molded products, sprayed with paint or bonded and compounded with other products. Through optimized combination of the fiber length, the strength of the molded product is improved, and through optimized combination of aluminum hydroxide and calcium carbonate, the flame retardant effect of the SMC sheet is guaranteed.

Owner:HENGSHUI YOUJIETE PETROLEUM EQUIP TECH CO LTD

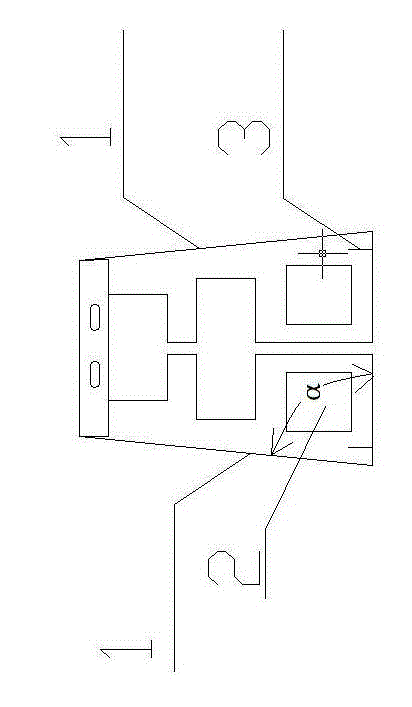

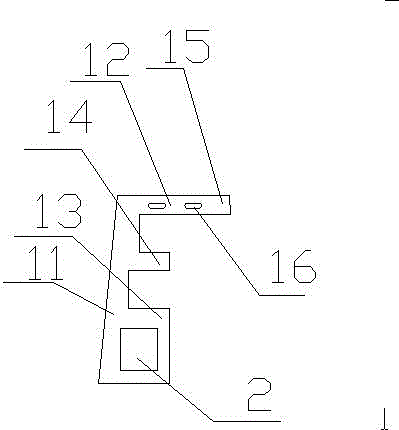

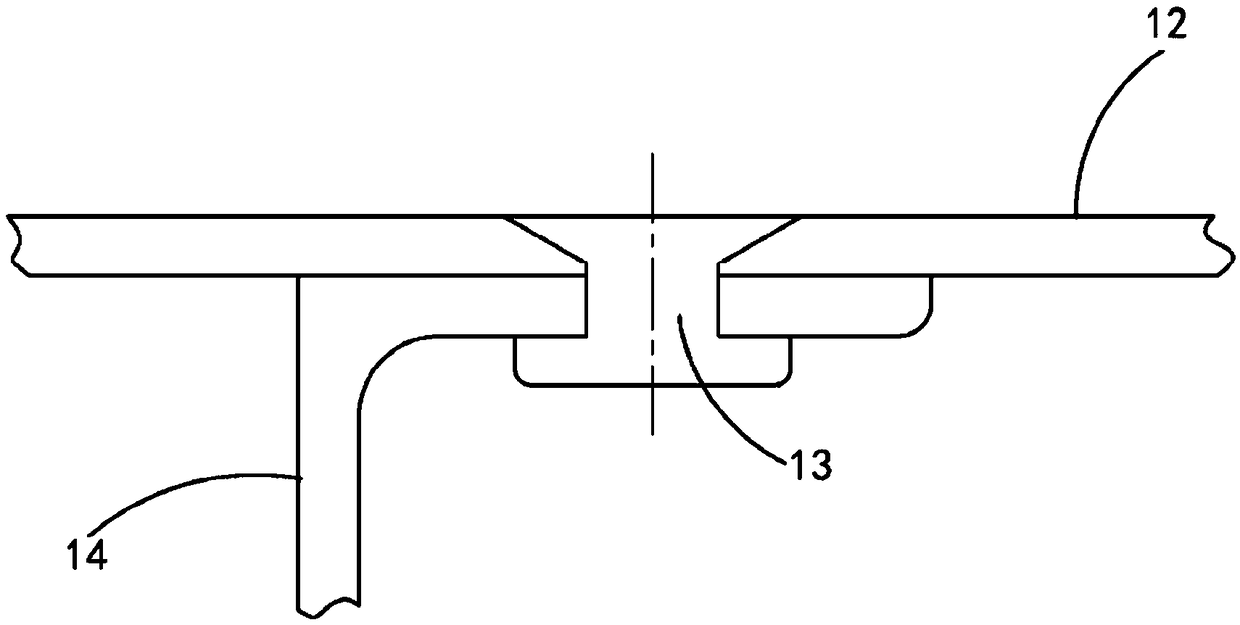

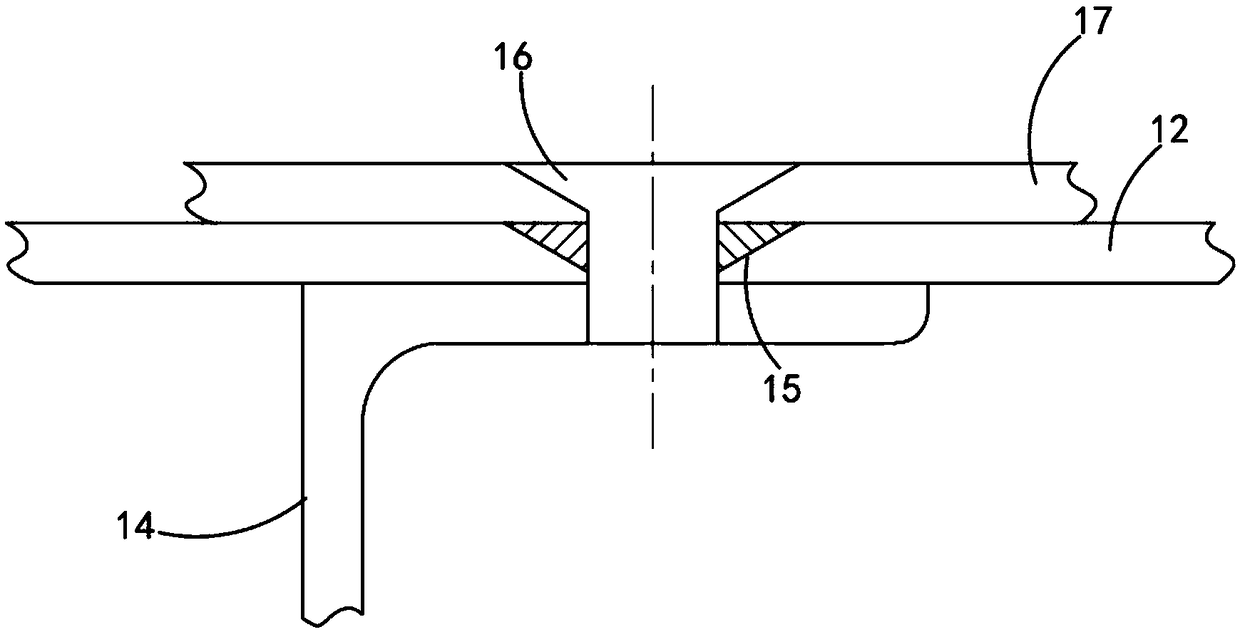

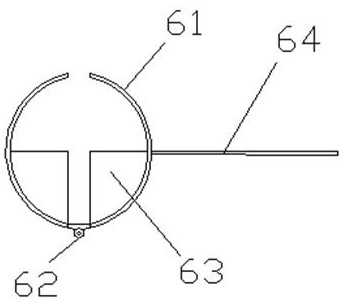

Special support tool for ship T-shaped bar

InactiveCN104590506AEasy to supportAccurate installation and positioningDry-dockingSlipwaysFastenerEngineering

The invention discloses a special support tool for a ship T-shaped bar. The special support tool comprises two plate members, wherein the plate members are oppositely arranged, and are connected into a whole by virtue of a fastening member, the plate members are integral members, the plate members comprise side plates, upper end plates, lower end plates and middle plates, wherein the upper end plates, the lower end plates and the middle plates are all vertically connected with the side plates to form E-shaped members, mounting plates which outwards horizontally extend are arranged at end heads of the upper end plates, mounting holes are formed in the mounting plates; square through holes are formed in the lower end plates; the outer side surfaces of the side plates are inclined surfaces, and included angles alpha are formed between the outer side surfaces of the side plates and the lower end plates, and are 84 DEG. Compared with the prior art, the special support tool has the characteristics of being accurate in positioning and convenient to mount. By using the special support tool, procedures of welding and grinding can be removed, so that excessive procedures are avoided, and thus the production time and cost are saved.

Owner:JIANGSU DAJIN HEAVY IND

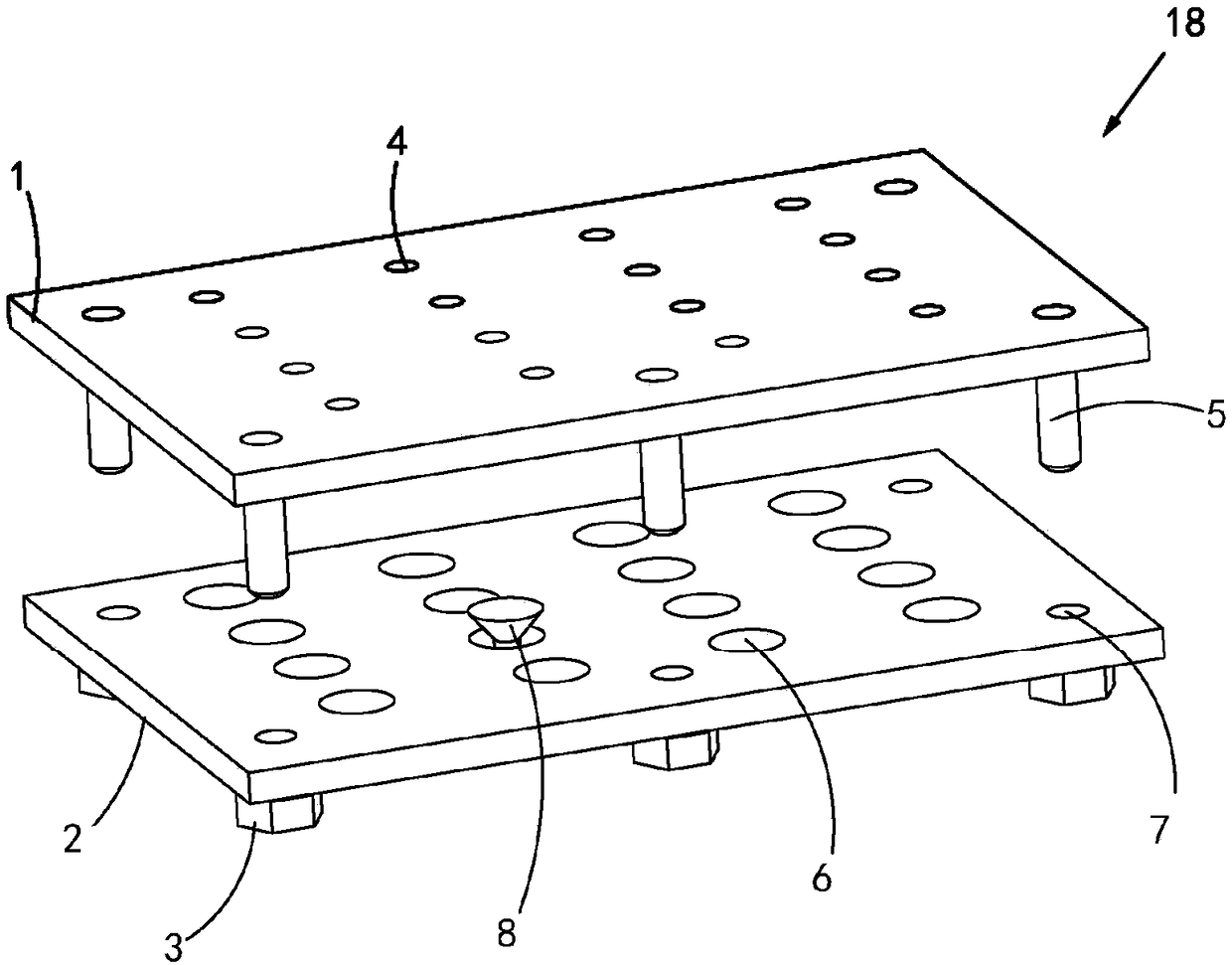

Rivet clamping assembly and method for using rivet clamping assembly to manufacture airplane skin maintenance gasket

The invention provides a rivet clamping assembly used for manufacturing a maintenance gasket needed by maintaining of airplane skin. The rivet clamping assembly comprises a first fixing plate, a second fixing plate and a locking nut. The first fixing plate is provided with a round hole and a screw rod. The second fixing plate is provided with a countersunk head rivet hole and a through hole. The countersunk head rivet hole comprises a conical countersunk head rivet part and a round hole part. The screw rod on the first fixing plate is matched with the through hole in the second fixing plate, and thus the first fixing plate and the second fixing plate are fixed together through the locking nut. When the second fixing plate and the first fixing plate are fixed together, the countersunk headrivet part of the countersunk head rivet hole in the second fixing plate faces one side, provided with the screw rod, of the first fixing plate, and the round hole in the first fixing plate is alignedto the round hole part of the countersunk head rivet hole in the second fixing plate. In addition, the invention further provides a method for using the rivet clamping assembly to manufacture the maintenance gasket needed by maintaining of the airplane skin.

Owner:TAIKOO XIAMEN AIRCRAFT ENG CO LTD

Nickel plating non-grinding process for production of printing roller

The invention relates to a nickel plating non-grinding process for production of a printing roller. The process specifically includes the following steps that (1) the printing roller to be plated with nickel is grinded, and the surface roughness of the printing roller is controlled to be smaller than or equal to Rz 0.3; (2) a nickel salt solution is prepared, half of the grinded printing roller is soaked in the nickel salt solution, a metal nickel block serves as a positive pole, the printing roller soaked in the nickel salt solution serves as a negative pole, the nickel salt solution is purified firstly, then nickel plating is conducted, and the nickel plating time is controlled to range from 250 seconds to 280 seconds; and (3) the printing roller with the surface plated with a nickel layer is placed in a nickel grinding groove, rotated, washed for 30-45 seconds with high-pressure water and then transferred to a copper tank rapidly, and then later copper-plating operations can be conducted. Compared with the prior art, the nickel plating non-grinding process has the advantages that the steps are simple, conditions are easy to control, washing is achieved through high-pressure water, grinding is avoided, and automatic control is realized; besides, the economic cost is low, copper-plating points can be effectively reduced, the quality stability of the obtained nickel-plated printing roller is good, and the process has good application prospects.

Owner:SHANGHAI YUNAN PLATE MAKING

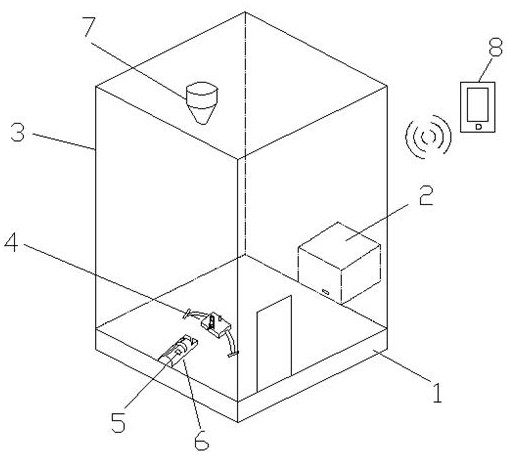

Intelligent laser nail clipper

The invention discloses an intelligent laser nail clipper which comprises a base, a shell, a laser system, a controller, a finger model and a limiting protection assembly, the shell is arranged on the base, the laser system is arranged at the top of the shell and points to the lower portion, and the finger model is arranged on the base and located below the laser system; the side face of the shell is provided with an insertion hole corresponding to the finger model, the limiting protection assembly is arranged on the base and located in front of the finger model, and the controller is connected with the laser system and the limiting protection assembly for control. By means of the mode, the intelligent laser nail clipper achieves scanning and automatic cutting of nails, is high in operation safety, enables nail trimming work to be easier and faster, and can trim nails in various target shapes.

Owner:SHAZHOU PROFESSIONAL INST OF TECH

Germany cream-colored stone imitation coating and preparation method thereof

The invention provides a Germany cream-colored stone imitation coating and a preparation method thereof. The bottom layer of the Germany cream-colored stone imitation coating is coated and flatten bythe aid of ceramic stone coatings, and the surface layer of the coating is coated and formed by sintering sand water sand stone imitation coatings. According to the coating, the ceramic stone coatingsand the sintering sand water sand coatings are creatively combined, ceramic stones can control thickness, particles have gaps, the sintering sand can be permeated into the gaps, so that the ceramic stones and the sintering sand are matched and supplemented each other, processes are simple, the coating is stable in performance, Germany cream-colored stone imitation effects are realistic, industrial large-scale production can be achieved, good economic benefits can be provided for enterprises, and the coating has a wide prospect.

Owner:上海贝塔建筑科技有限公司

Process for processing connection type building template

InactiveCN103612077ALow damage valueImprove welding precisionLaser beam welding apparatusConnection typeEngineering

The invention relates to the field of building templates and particularly discloses a process for processing a connection type building template. The process for processing the connection type building template is characterized by comprising the steps of selecting a galvanized square tube, a galvanized steel plate, galvanized round tubes and nuts; performing length cutting after the galvanized square tube is subject to blanking, and cutting evenly-distributed pore diameters on the steel tube simultaneously; arranging the galvanized round tubes or the nuts in the pore diameters of the galvanized square tube, performing laser welding to form a frame body, and performing laser welding of the galvanized steel plate on the frame body. The process for processing the connection type building template has a higher welding precision than other welding processes, welding joints are flat, no polishing is required, artificial investment and electric energy are saved, a material damage value is the minimum, no pollution link occurs in the whole production process, and the process is suitable for being widely popularized and applied.

Owner:刘红艳

Injection-compression molding method for glass fiber reinforced plastic fairing of locomotive

An injection-compression molding method for a glass fiber reinforced plastic fairing of a locomotive belongs to the technical field of manufacturing methods for glass fiber reinforced plastic fairings of locomotives, and aims to solve the technical problem of providing a manufacturing method for a glass fiber reinforced plastic fairing of a locomotive, wherein the glass fiber reinforced plastic fairing is economical, environment-friendly and attractive in appearance. The technical scheme includes that the injection-compression molding method for the glass fiber reinforced plastic fairing of the locomotive includes the steps: firstly, manufacturing an upper mould; secondly, laying layers and then spreading a continuous felt on the topmost layer of a lower mould; thirdly, closing the moulds; fourthly, vacuumizing for glue injection; fifthly, solidifying and drawing; sixthly, grinding and painting; and seventhly, repeating the second step to the sixth step to manufacture a next fairing. The injection-compression molding method is used for manufacturing the glass fiber reinforced plastic fairing of the locomotive.

Owner:大同机车新型材料制品有限责任公司

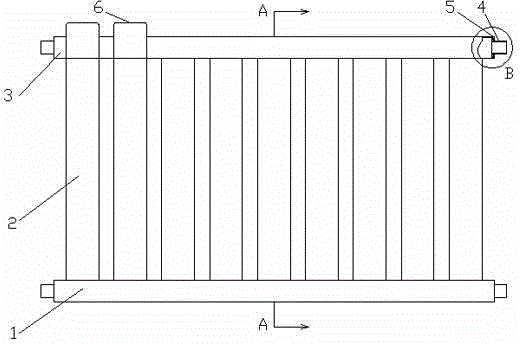

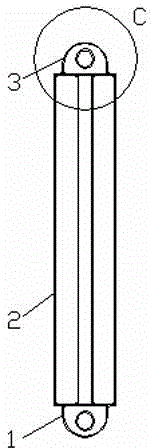

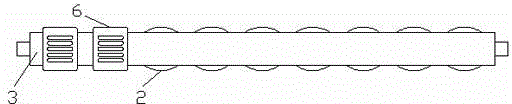

Double-column radiator and manufacturing method thereof

ActiveCN104896570AImprove cooling effectCoordinated and beautiful appearanceLighting and heating apparatusSpace heating and ventilation detailsEngineeringWelding

The invention discloses a double-column radiator and a manufacturing method thereof. The double-column radiator of the invention comprises a lower beam, an upper beam and radiating pipes, wherein the upper beam and the lower beam have the same structure, and each of the upper beam and the lower beam comprises an upper cover and a bottom plate; the upper covers and the bottom plates are welded together through two abreast radiating pipes; connecting water nozzles are arranged on two ends of the upper beam and the lower beam, and are fixedly connected with the upper beam and the lower beam through nozzle sealing plates. The double-column radiator has no weak points in lateral connection and has high strength; when mounting, a colorful cap is mounted on the upper beam, so that the radiating effect of the radiator is improved and the integral appearance is more coordinated and attractive; when manufacturing, the welding position is flat edge welding, so as to omit the polishing process, reduce the welding difficulty, shorten the production process, reduce the labor intensity of workers, ensure the welding quality and improve the yield.

Owner:圣劳伦斯(唐山)金属制品有限公司

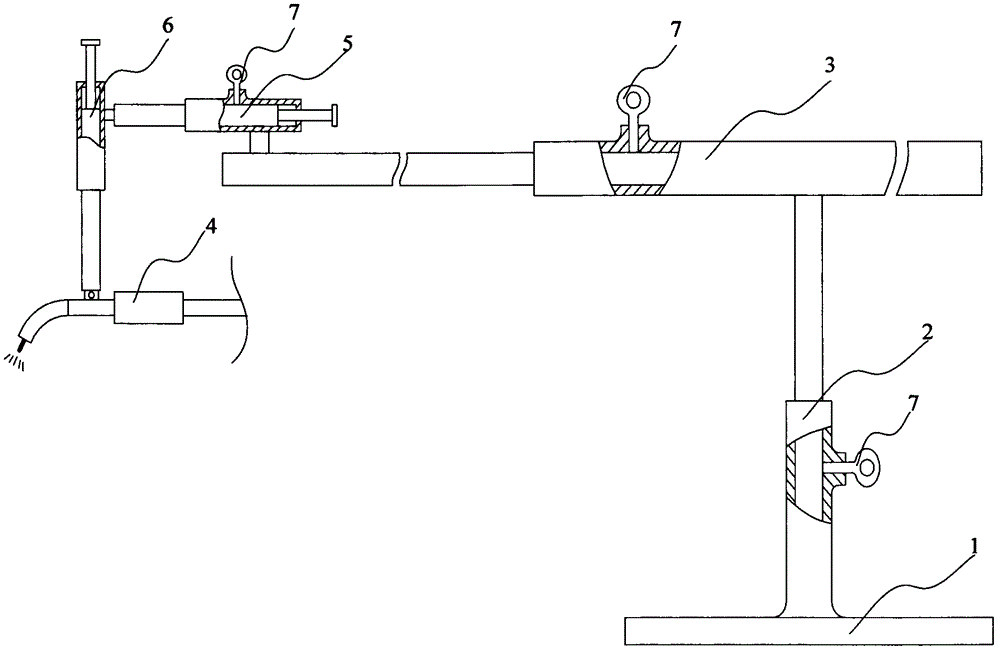

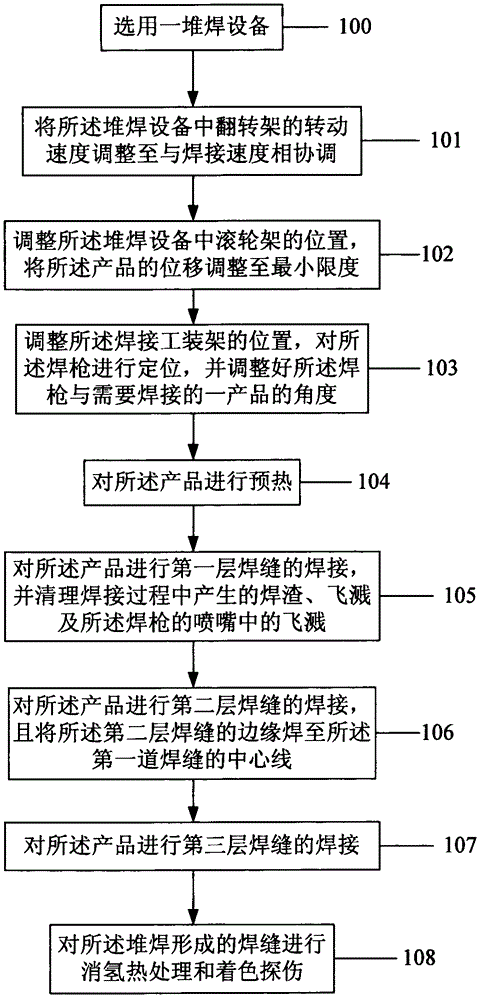

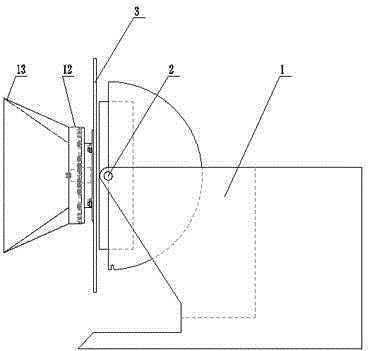

Welding tool frame for carbon dioxide gas shielded welding and its welding method

ActiveCN102581452BReduce labor intensityReduce radiationElectrode supporting devicesDye penetrant inspectionPetroleum engineering

The invention discloses a welding tooling support for carbon dioxide arc welding. The welding tooling support comprises a base and an adjusting device for adjusting a welding torch, wherein one end of the adjusting device is fixed on the base, and the other end of the adjusting device is connected with the welding torch. The invention further discloses a welding method in which the welding tooling support is utilized. The welding method comprises step 1 adjusting the position of the welding tooling support, positioning the welding torch, and adjusting an angle formed by the welding torch and a product to be welded; step 2 preheating the product; step 3 subjecting the product to surfacing; and step 4 subjecting welding seams formed by surfacing to hydrogen relief heat treatment and dye penetrant inspection. The welding tooling support for carbon dioxide arc welding reduces labor intensity of welders and improves welding quality and production efficiency. According to the welding method, short time is required, continuous welding is achieved, time of replacing welding electrodes is decreased, and welding cycle is shortened.

Owner:SHANGHAI BOILER WORKS

Ring-cutting knife

InactiveCN100411785CSimple structureEasy to useTransportation and packagingTrepanning drillsEngineeringWrench

The invention discloses a paring circle knife, comprising location bearing and cylindrical hollow cutting knife which is nested on the location bearing through center hole. The cylindrical hollow cutting knife can move up and down. On the back of cylindrical hollow cutting knife there is breather, the head of it there are hackly cutting edges, and on the knife there are arrises. The invention has the advantages of simple structure, easy operation, and wide application. The invention is especially used to maintain the mine equipments.

Owner:王中华

Processing technology of connected building formwork

InactiveCN103612077BLow damage valueImprove welding precisionLaser beam welding apparatusConnection typePore diameter

The invention relates to the field of building templates and particularly discloses a process for processing a connection type building template. The process for processing the connection type building template is characterized by comprising the steps of selecting a galvanized square tube, a galvanized steel plate, galvanized round tubes and nuts; performing length cutting after the galvanized square tube is subject to blanking, and cutting evenly-distributed pore diameters on the steel tube simultaneously; arranging the galvanized round tubes or the nuts in the pore diameters of the galvanized square tube, performing laser welding to form a frame body, and performing laser welding of the galvanized steel plate on the frame body. The process for processing the connection type building template has a higher welding precision than other welding processes, welding joints are flat, no polishing is required, artificial investment and electric energy are saved, a material damage value is the minimum, no pollution link occurs in the whole production process, and the process is suitable for being widely popularized and applied.

Owner:刘红艳

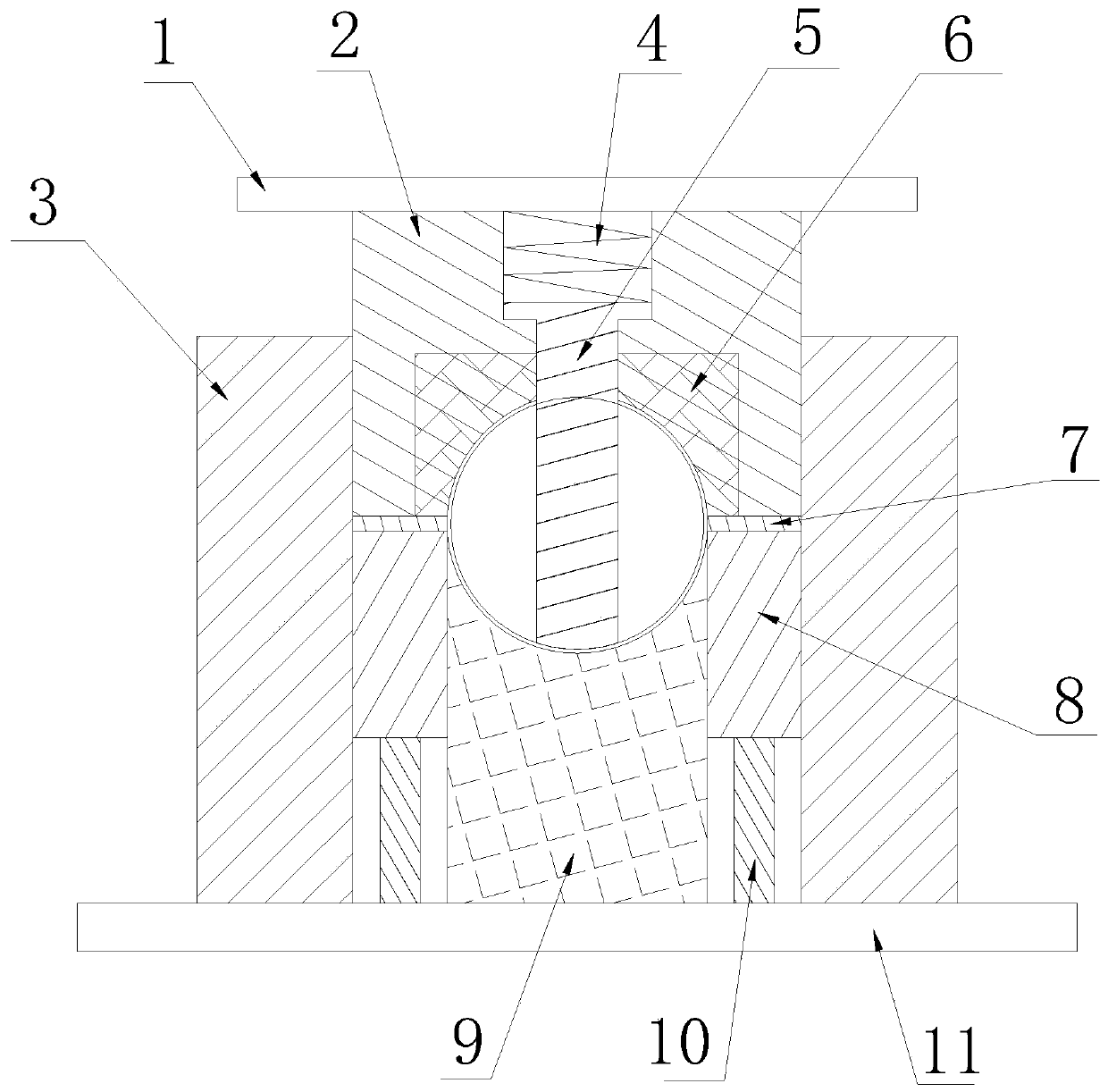

Split type mold for hollow sphere precise manufacturing

The invention discloses a split type mold for hollow sphere precise manufacturing. The mold comprises an upper bottom plate and a lower bottom plate, upper molds are arranged on the two sides of the bottom of the upper bottom plate, the two outer sides of the upper molds are attached to an outer guide mold, a compression spring is arranged between the upper molds, the bottom of the compression spring is connected with an upper mold inner material returning rod, upper mold inner phase blocks are arranged on the two sides of the upper mold inner material returning rod, telescopic pieces are tightly attached to the bottoms of the upper mold inner phase blocks, guide rings are arranged at the bottoms of the telescopic pieces, a lower mold is arranged between the guide rings, ejector rods are arranged on the bottom of the guide rings, and a lower bottom plate is arranged on the bottoms of the ejector rods. A made hollow sphere is free of welding, saves time and materials, is simple in structure, small in round degree and small in single hole.

Owner:泰州市姜堰区银星冲压制品厂

Bidirectional adjustable cylindrical welding anti-deformation fixture

ActiveCN102896455BAvoid welding deformationImprove molding qualityWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention relates to a bidirectional adjustable cylindrical welding anti-deformation fixture which comprises a rotary table, a central compressing component and more than three groups of movable supporting components, wherein the central compressing component is arranged on the rotary table, the rotary table is in a rotation state around the central compressing component, the more than three groups of movable supporting components are uniformly distributed on the rotary table around the central compressing component, and the central compressing component props against the more than three groups of movable supporting components so that the movable supporting components are simultaneously extended outwards or simultaneously retracted. According to the bidirectional adjustable cylindrical welding anti-deformation fixture disclosed by the invention, the central compressing component drives the movable supporting components to prop against and fix a cylinder workpiece, and the rotary table capable of rotating in plane and space drives the cylinder workpiece to rotate in two directions by supporting the movable supporting components so that the cylinder workpiece is located and welded; in addition, the bidirectional adjustable cylindrical welding anti-deformation fixture disclosed by the invention has the advantages of simple structure, convenience in operation, low cost and good welding effect; and the welded workpiece has less possibility of deformation.

Owner:JIANGSU JOSUN SCI&TECH CO LTD

Bottom-surface integrated shell powder coating and preparation method thereof

PendingCN114395281AReduce pollutionImprove waterproof performanceFireproof paintsLime coatingsPropanolPolyvinyl alcohol

The invention discloses a bottom surface integrated shell powder coating which is prepared from the following components: high-temperature calcined shell powder, ash calcium, kaolin, talcum powder, latex powder, polyvinyl alcohol, titanium dioxide, cellulose, quartz sand, a water reducing agent, a thickening lubricant, a water-resistant agent, bentonite, propyl alcohol ether, glass beads, three-dimensional porous bi-crosslinking polyaniline / graphene composite xerogel and white cement. Due to addition of the glass beads, the coating can be used as a bottom surface material and a decorative material, bottom putty is not needed, the bottom surface is integrated, polishing is not needed, pollution is reduced, and the coating has moisture-proof, mildew-proof, fireproof, elastic and anti-cracking effects. Meanwhile, by adding iron-silicon modified bentonite, the waterproof performance of the coating is remarkably improved; by adding the three-dimensional porous bi-crosslinked polyaniline / graphene composite xerogel, the wear resistance and cracking resistance of the coating are remarkably improved.

Owner:天津蓝海优贝科技有限公司

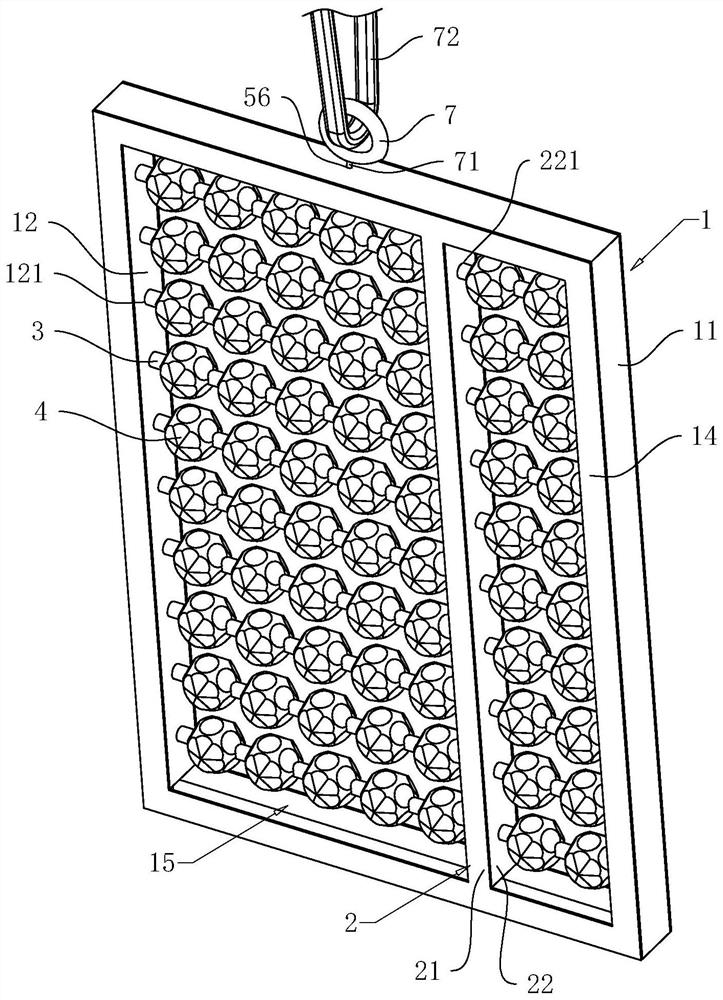

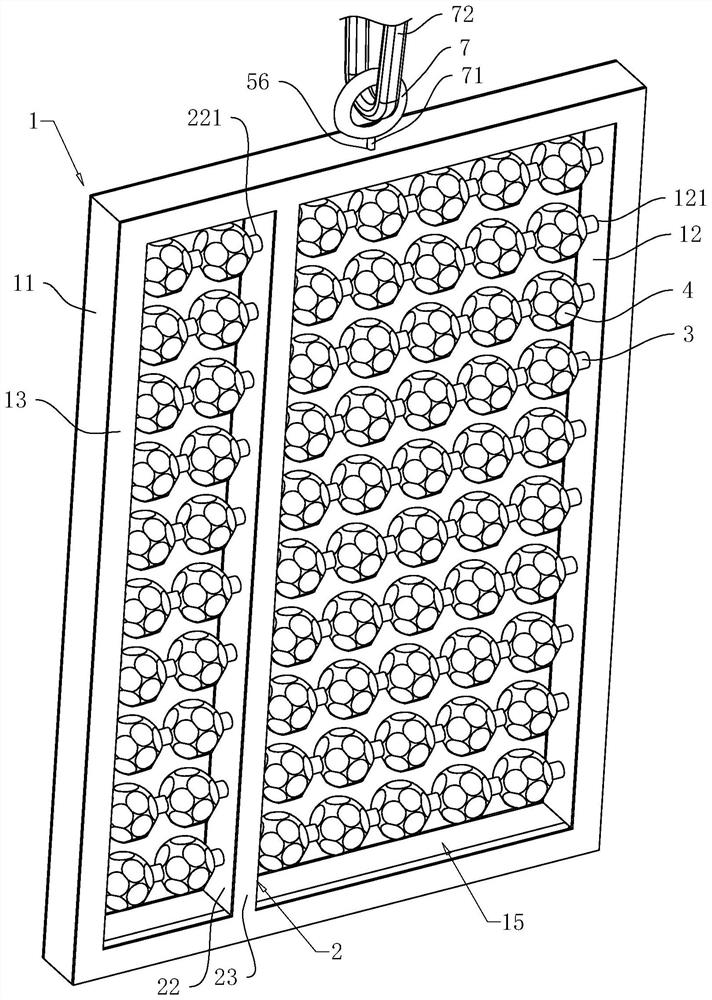

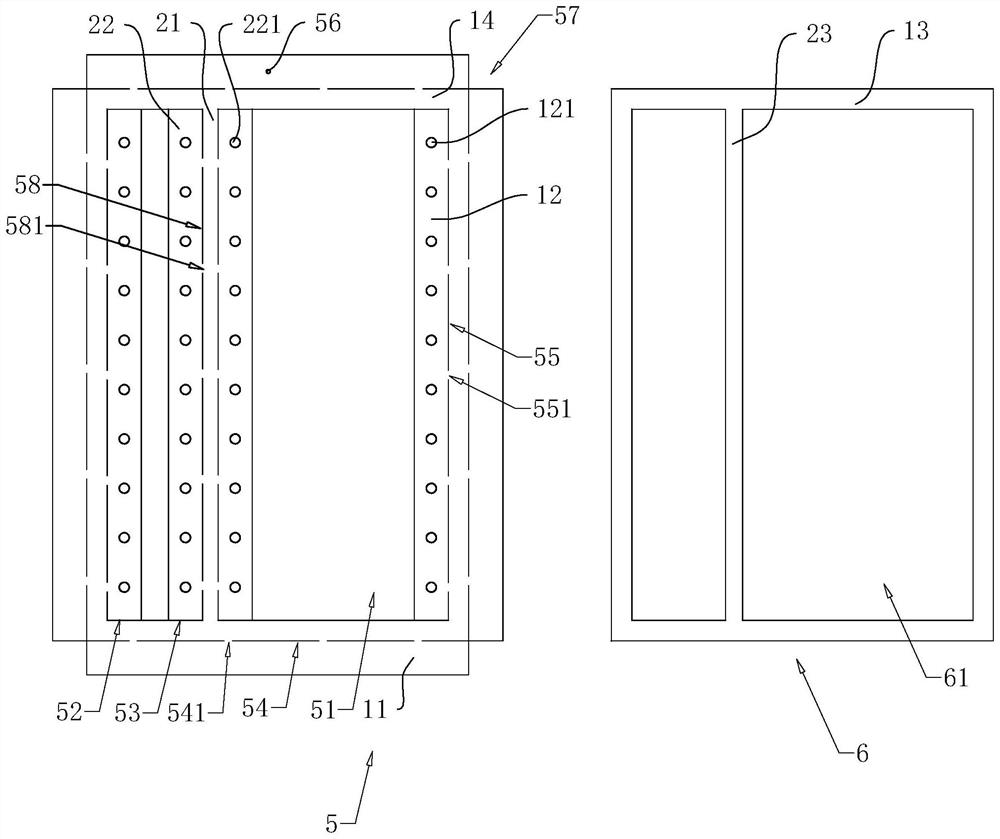

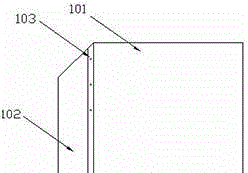

Pendant and manufacturing process thereof

Owner:深圳市冠华珠宝有限公司

Assembling type intelligent express item box

InactiveCN105989676ASimple structureHigh degree of production automationApparatus for meter-controlled dispensingComputer hardwareLED display

The invention provides an assembling type intelligent express item box, and relates to an intelligent express item box and an intelligent self-service express item cabinet, in particular to self-service equipment of a logistic terminal and intelligent logistic equipment. The assembling type intelligent express item box comprises a control mainboard, a display screen, an electronic lock, a power source and a cabinet body, the power source is connected with the control mainboard, the display screen and the electronic lock. The cabinet body is formed by assembling an iron plate and fastened by a screw or a rivet. The iron plate is a galvanized iron sheet. The iron plate is formed by cold rolling. The intelligent express item box further comprises a network communication module. The network communication module is connected with the control mainboard and the power source. The intelligent express item box further comprises an image collection module. The image collection module is connected with the control mainboard and the power source. The intelligent express item box further comprises a loudspeaker. The loudspeaker is connected with the control mainboard and the power source. The display screen is an LCD display screen or an LED display screen. The intelligent express item box further comprises a coin insertion module. The coin insertion module is connected with the control mainboard and the power source.

Owner:章玺

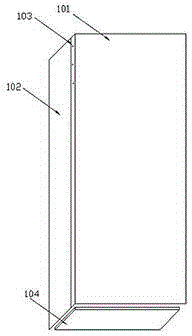

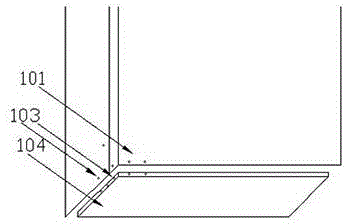

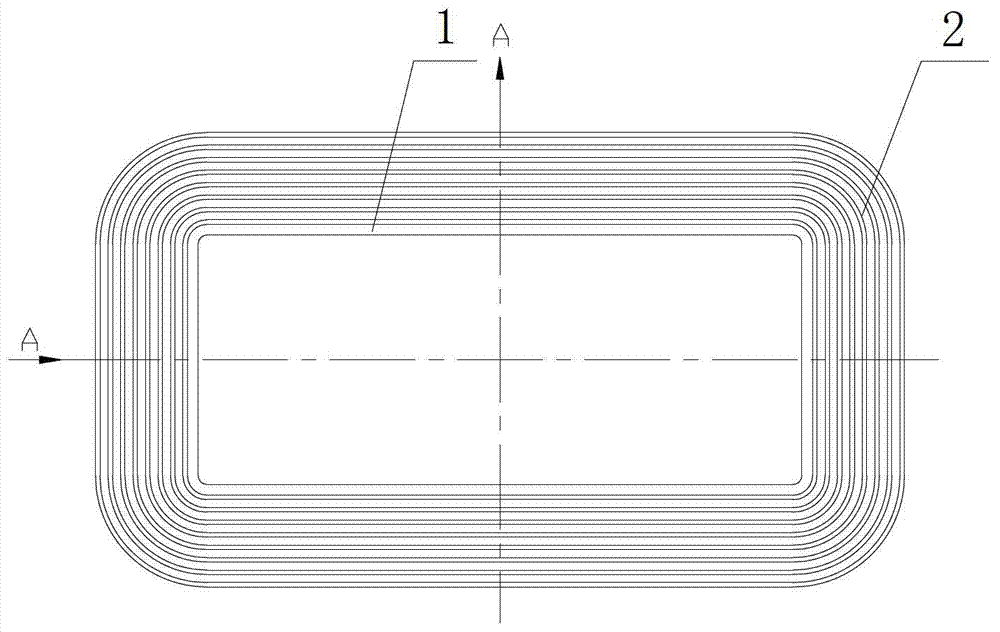

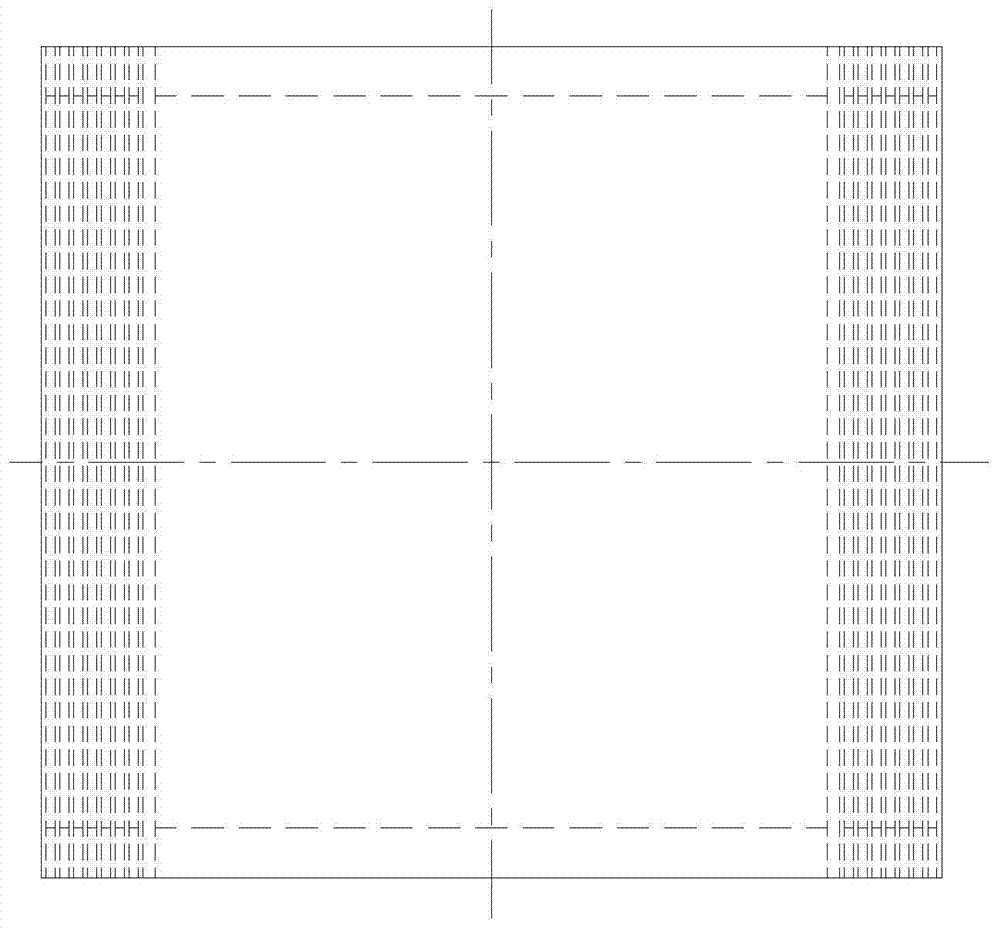

A structure and method for end insulation of a dry-type transformer

InactiveCN104240921BSimple processReduce processing costsTransformers/inductances coils/windings/connectionsCoils manufactureEnvironmental resistanceEpoxy

The invention relates to a structure and method for end insulation of a dry-type transformer. An insulating end ring, which is located between the layers of insulation and abuts against the conductive foil. Use single-layer or multi-layer pre-impregnated epoxy DMD as the end ring material, cut it into the required width and wind it into a package, and then select the corresponding thickness and number of layers according to the thickness of the coil conductive foil (wire). When the coil is wound It is wound together with conductive foil (wire) and layer insulation. Compared with the prior art, the invention has the advantages of simple process, low processing cost, environmental protection and the like.

Owner:SHANGHAI FLYING KING ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com