Stamping embedded hard sealing nuclear power air valve

A hard-sealed and inlaid technology, which is applied in the direction of lift valves, valve devices, engine components, etc., can solve the problems of easy welding, hard-to-handle coating, and heavy workload, so as to save production costs, secure and reliable connection points, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

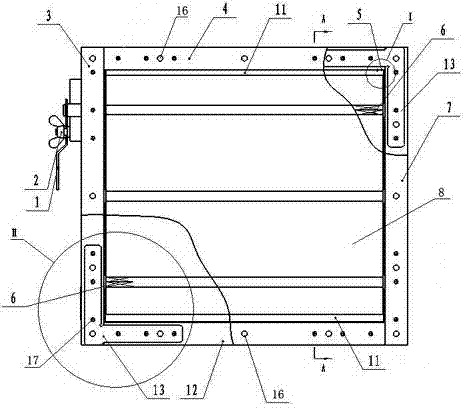

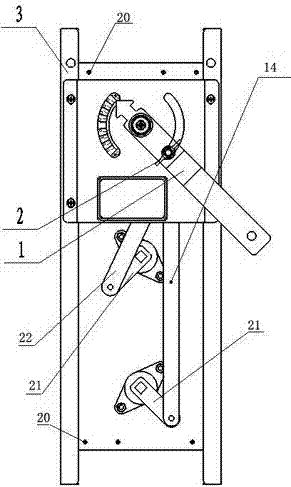

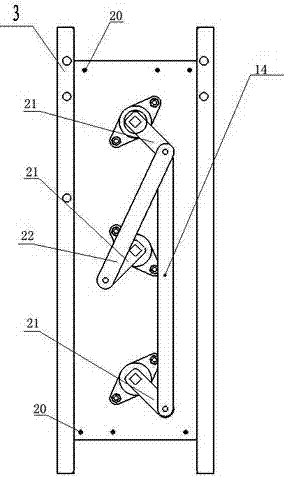

[0033] Depend on Figure 1-12 As can be seen from the illustrated embodiment, it includes a valve body, a valve seat 11, a valve plate and a transmission mechanism; the valve body includes upper and lower frames 4, 12, left and right side frames 3, 7; Rod mechanism, handle 1 and locking device 2; the valve plate is composed of three blades and their corresponding rotating shafts 6; it is characterized in that it also includes an inner angle iron 5 and a connecting angle iron 13; the upper and lower frames 4, The front and rear sides of 12 are respectively connected with the corresponding valve seat 11 by stamping and inlaying; the upper and lower frames 4, 12 and the left and right side frames 3, 7 are connected with the inner angle iron 5 by rivets 20 to form a valve body frame, The eight corners of the valve body frame are respectively stamped and inlaid with the corresponding connecting angle irons 13;

[0034] The blade is composed of a pair of symmetrical front and rear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com