A structure and method for end insulation of a dry-type transformer

A technology of dry-type transformer and end insulation, applied in the direction of transformer/inductor coil/winding/connection, coil manufacturing, etc., which can solve the problems of difficult control of coil height and flatness, human body and environment impact, easy leakage, etc. It achieves the effects of easy control of height and end surface flatness, low processing cost and high mechanical strength

Inactive Publication Date: 2017-09-05

SHANGHAI FLYING KING ELECTRIC

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This method is relatively simple in terms of equipment and process requirements, and the cost is not high, but it is easy to leak during the end-sealing process, which requires repeated filling. After the end-sealing process, the end part needs to be polished. And the end sealing waste and the dust in the grinding process will have a certain impact on the human body and the environment

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

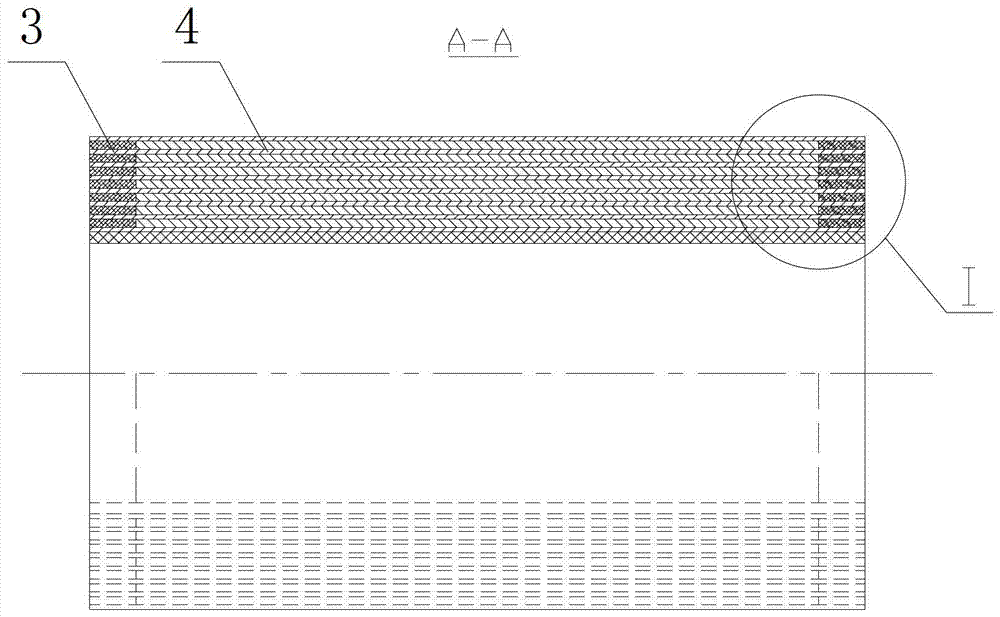

[0035] The invention is made by using the end ring made of DMD pre-impregnated with epoxy as the end insulation of the low-voltage coil of the dry-type transformer. The manufacturing method of the present invention will be described below by taking the section insulation of the end coil of the low-voltage coil of a 630kVA dry-type transformer as an example.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

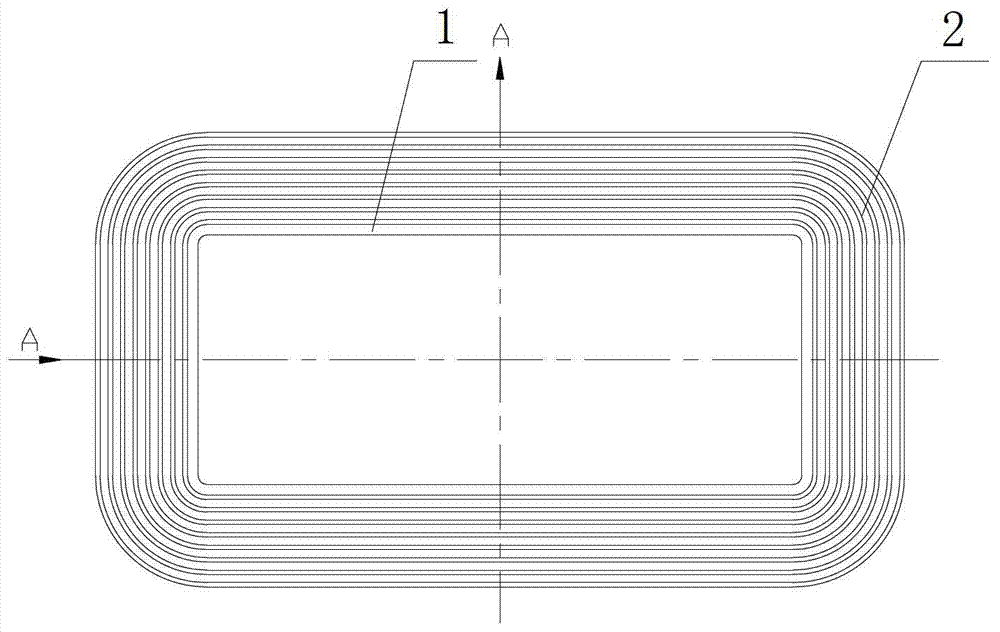

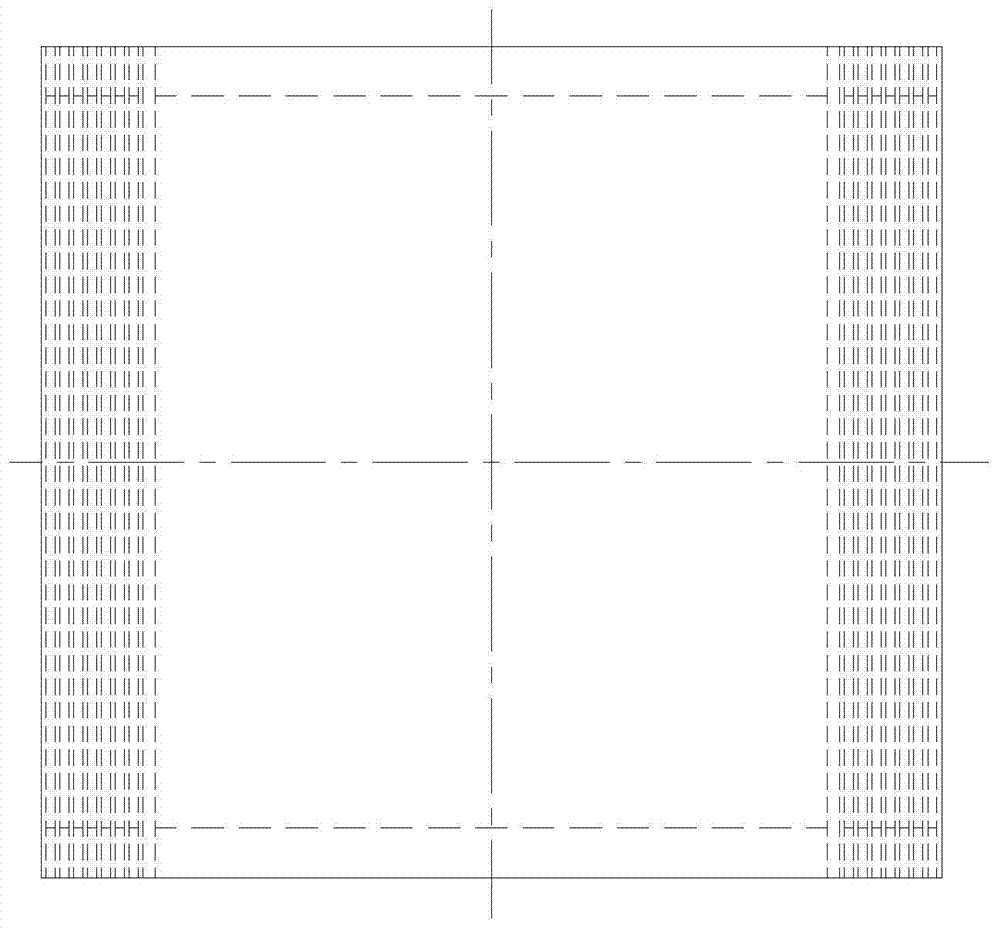

The invention relates to a structure and method for end insulation of a dry-type transformer. An insulating end ring, which is located between the layers of insulation and abuts against the conductive foil. Use single-layer or multi-layer pre-impregnated epoxy DMD as the end ring material, cut it into the required width and wind it into a package, and then select the corresponding thickness and number of layers according to the thickness of the coil conductive foil (wire). When the coil is wound It is wound together with conductive foil (wire) and layer insulation. Compared with the prior art, the invention has the advantages of simple process, low processing cost, environmental protection and the like.

Description

technical field [0001] The invention relates to a transformer end insulation method, in particular to a structure and method for dry-type transformer end insulation. Background technique [0002] As the main insulation structure of the coil, the end insulation of the low-voltage coil of the dry-type transformer not only plays the role of insulation, but also supports the coil and other components. At present, the domestic coil end insulation is mainly divided into two methods: integral epoxy casting of the coil and end epoxy sealing. The characteristics are as follows: [0003] 1. Integral casting of the coil: the low-voltage coil adopts the epoxy casting of the end and the coil as a whole, which has good insulation and mechanical strength, good-looking appearance, safety and reliability, but it needs to make a special casting mold and pour it through special casting equipment, and The mold is not universal, and the mold is expensive. This structure has poor heat dissipati...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H01F27/32H01F27/29H01F41/12

Inventor 张太平

Owner SHANGHAI FLYING KING ELECTRIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com