Formula of polyvinyl chloride (PVC) foamed sheet and preparation method thereof

A technology of foamed sheet and formula, which is applied in the field of PVC foamed sheet formulation and its preparation, can solve problems such as poor surface finish, uneven board surface, and thin crust thickness, and achieve excellent foaming effect, excellent material performance, The effect of reducing the scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

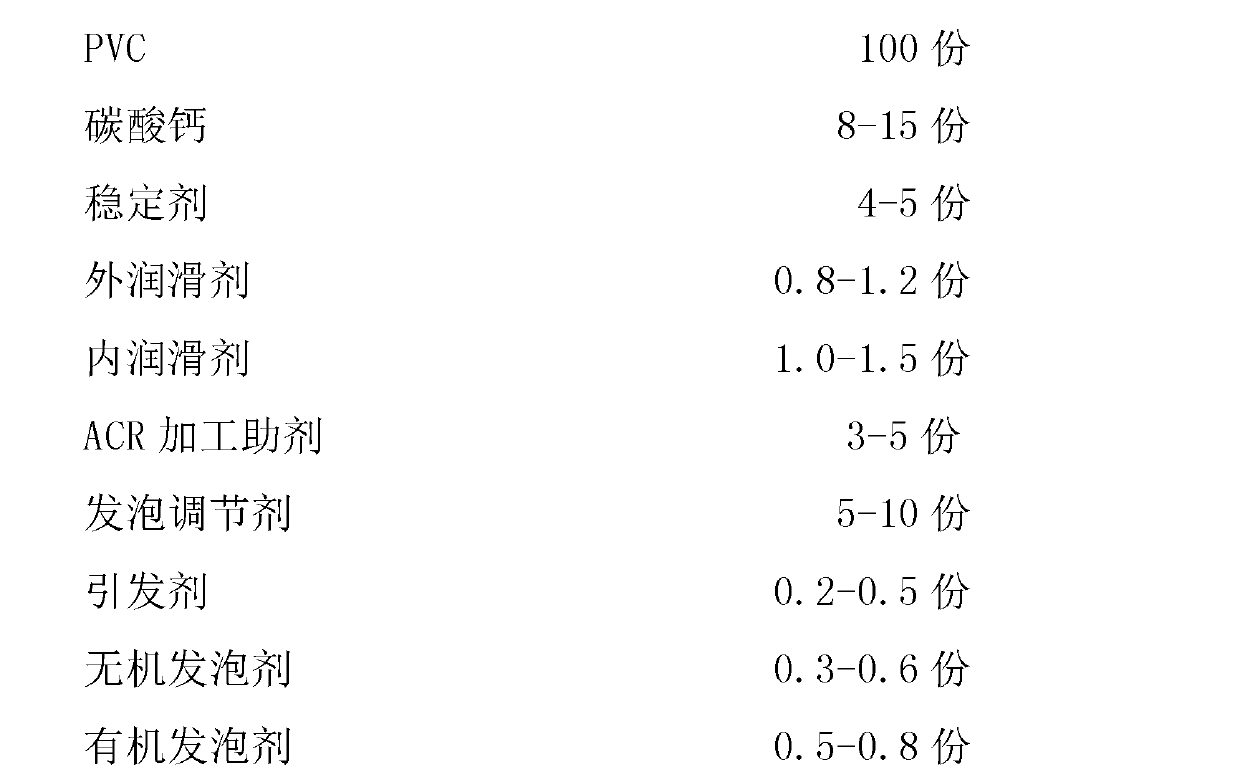

Embodiment 1

[0035]

[0036] After automatic metering, the various components are added to the hot mixer and mixed to 110°C. The material is cooled in the cold mixer. After cooling to 45°C, the material is transported to the mixing tank for storage and homogenization by Roots blower. After 24 hours , through the extruder under certain process conditions, plasticized and shaped, then cut and packaged.

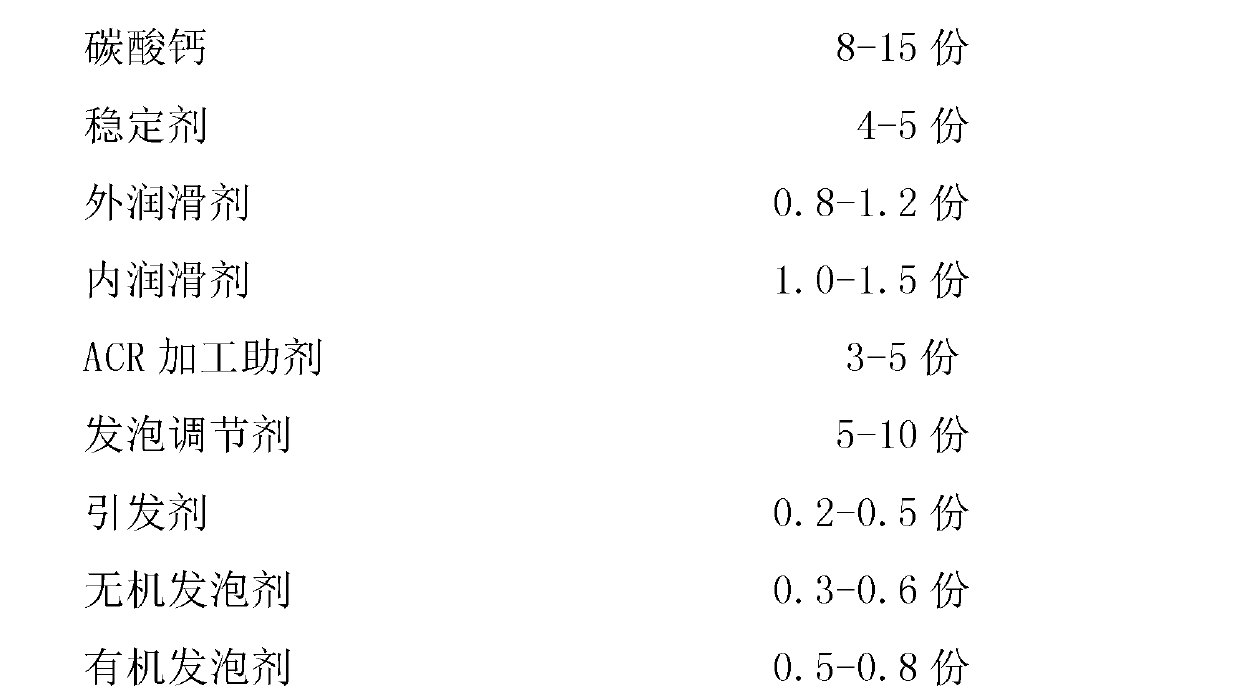

Embodiment 2

[0038]

[0039]

[0040] After automatic metering, the various components are added to the hot mixer and mixed to 110°C. The material is cooled in the cold mixer. After cooling to 45°C, the material is transported to the mixing tank for storage and homogenization by Roots blower. After 24 hours , through the extruder under certain process conditions, plasticized and shaped, then cut and packaged.

Embodiment 3

[0042]

[0043] After automatic metering, the various components are added to the hot mixer and mixed to 110°C. The material is cooled in the cold mixer. After cooling to 45°C, the material is transported to the mixing tank for storage and homogenization by Roots blower. After 24 hours , through the extruder under certain process conditions, plasticized and shaped, then cut and packaged.

[0044] Table 1 is the performance test data of embodiment 1-3 and its comparison with prior art and industry standard

[0045]

[0046] Table 1

[0047] The standards mentioned in the above table are the standards stipulated in GB / T2463.2-1999 "Rigid Polyvinyl Chloride Low-foaming Sheet Plug Luca Law".

[0048] As shown in table 1: embodiment 1-3 all can realize the present invention, and its foaming density is lower, surface Shore hardness is high, rigidity and toughness are better in terms of material performance, and each technical index is all obviously better than existing techno...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com