Special support tool for ship T-shaped bar

A technology for profiles and ships, which is applied in the direction of berth, dry dock, transportation and packaging, etc., can solve the problems of unfavorable welding deformation, easily damaged steel, and substandard precision, and achieve the effects of saving manpower, accurate installation and positioning, and convenient support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

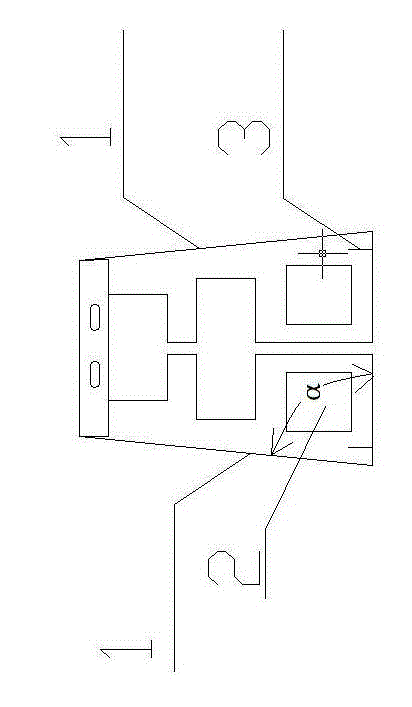

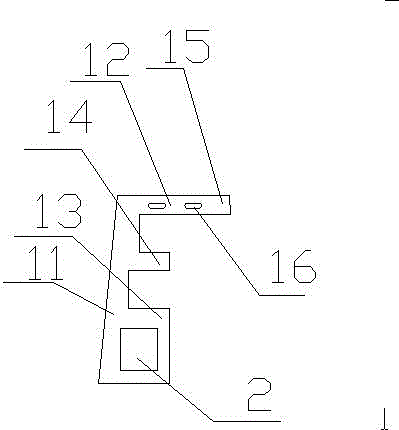

[0020] As shown in the figure, a special support tool for ship T-shaped bar, including two plates 1, the plates 1 are arranged opposite to each other, connected into one body by bolts or other fasteners, the plates 1 are integral components, The panel 1 comprises a side plate 11, an upper end plate 12, a lower end plate 13 and a middle plate 14, the upper end plate 12, the lower end plate 13 and the middle plate 14 are distributed parallel to each other, and are all vertically connected to the side plate 11 to form a E-shaped member, the end of the upper end plate 12 is provided with a mounting plate 15 extending horizontally outwards, the mounting plate 15 is provided with mounting holes 16, the number of mounting holes is not limited, it can be 2 or more , the mounting holes are arranged in the horizontal direction, and the lower end plate 13 is provided with a square through hole 2; the outer surface of the side plate 11 is a slope, and an angle α is formed between the outer...

Embodiment 2

[0022] As shown in the figure, a special support tool for ship T-shaped bar, including two plates 1, the plates 1 are arranged opposite to each other, connected into one body by bolts or other fasteners, the plates 1 are integral components, The panel 1 comprises a side plate 11, an upper end plate 12, a lower end plate 13 and a middle plate 14, the upper end plate 12, the lower end plate 13 and the middle plate 14 are distributed parallel to each other, and are all vertically connected to the side plate 11 to form a E-shaped member, the end of the upper end plate 12 is provided with a mounting plate 15 extending horizontally outwards, the mounting plate 15 is provided with mounting holes 16, the number of mounting holes is not limited, it can be 2 or more , the mounting holes are arranged in the horizontal direction, and the lower end plate 13 is provided with a square through hole 2; the outer surface of the side plate 11 is a slope, and an angle α is formed between the outer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com