Roll type strip unwinding device

A technology of unwinding device and strip, which is applied in the direction of winding strip, transportation and packaging, thin material handling, etc., can solve the problems of low work efficiency, damage to strip rolls, easy occurrence of safety accidents, etc., and achieve smooth unwinding. , The strip is straight and the work is reliable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

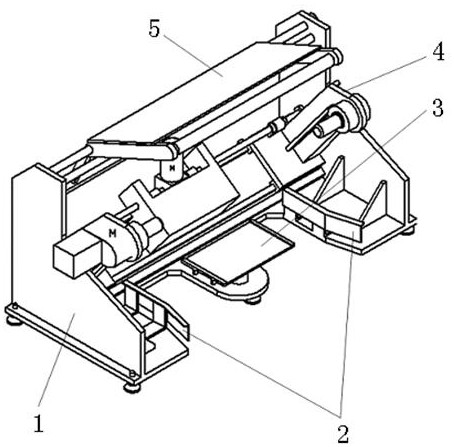

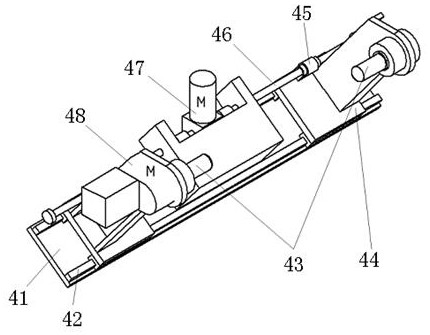

[0014] The roll-type strip unwinding device provided by the present invention comprises a base 1, which is provided with an unwinding mechanism 4, and the unwinding mechanism 4 includes a base plate 41, a slide rail 42 arranged on the base plate 41, and a slide rail 42 sliding seat 44 that is fitted, rotates the unwinding shaft 43 that is fixed on the upper end of the sliding seat 44 by the belt seat bearing, and drives the screw assembly that the sliding seat 44 and the unwinding shaft 43 on the sliding seat 44 move, such as figure 1 ;

[0015] The slide 44 and the unwinding shaft 43 on it are oppositely arranged with two, one of which is connected to the reel motor 48 after the outer end of the unwinding shaft is extended to form an active unwinding shaft, and the two unwinding shafts 43 are respectively placed on two sides of the strip reel. In the cylinder hole at the end, so that the active unwinding shaft and the other unwinding shaft 43 drive the strip coil to rotate sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com