Telescopic supporting leg and vehicle

A technology of telescopic outriggers and telescopic oil cylinders, which is applied in the field of vehicles, can solve problems such as difficult maintenance and unfavorable wire harness protection, and achieve the effect of easy support and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

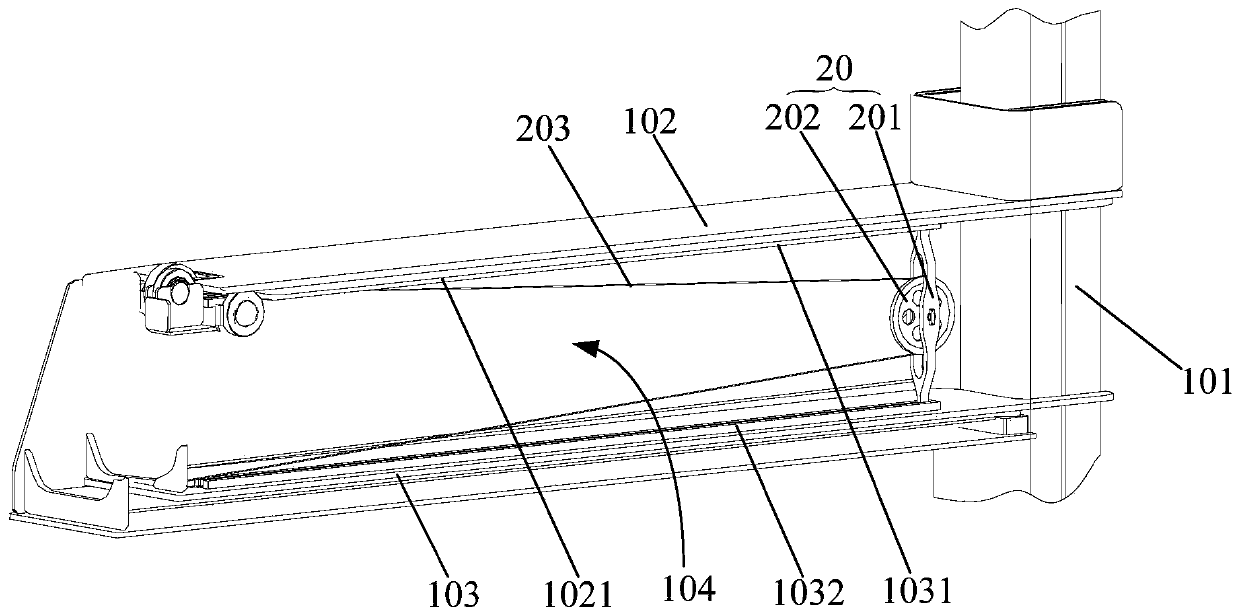

[0044] Such as figure 1 As shown, the embodiment of the first aspect of the present invention provides a telescopic outrigger 1 , including a outrigger assembly and a movable roller assembly 20 . The leg assembly includes a vertical leg 101, an outer leg 102 connected to the vertical leg 101 and an inner leg 103 located inside the outer leg 102 and connected to the vertical leg 101, the inner leg 103 defines a Mounting cavity 104; movable roller assembly 20 comprises the roller bracket 201 that is arranged in the mounting cavity and the movable roller 202 that is arranged on the roller bracket 201, and movable roller 202 is used for winding cable; Wherein, the upper wall surface of mounting cavity 104 and / or Or the lower wall surface is provided with a sliding part, and the roller bracket 201 is provided with a sliding fitting part, and the sliding fitting part cooperates with the sliding part, so that the movable roller assembly 20 is suitable for reciprocating sliding relati...

Embodiment 2

[0048] Embodiment 2 (not shown in the figure)

[0049] The difference from Embodiment 1 is that the sliding part includes an upper guide hole and a lower guide hole, the upper guide hole and the lower guide hole are respectively arranged on the upper wall surface and the lower wall surface of the installation cavity 104, and extend along the length direction of the inner leg 103 respectively The sliding fitting part includes an upper guide column and a lower guide column, the upper guide column and the lower guide column are respectively arranged on the upper end and the lower end of the roller bracket 201, and the upper guide column and the lower guide column are respectively inserted in the upper guide hole and the lower guide hole .

[0050] The sliding part includes an upper guide hole and a lower guide hole respectively arranged on the upper wall surface and the lower wall surface of the installation cavity 104, and the upper guide hole and the lower guide hole are respec...

Embodiment 3

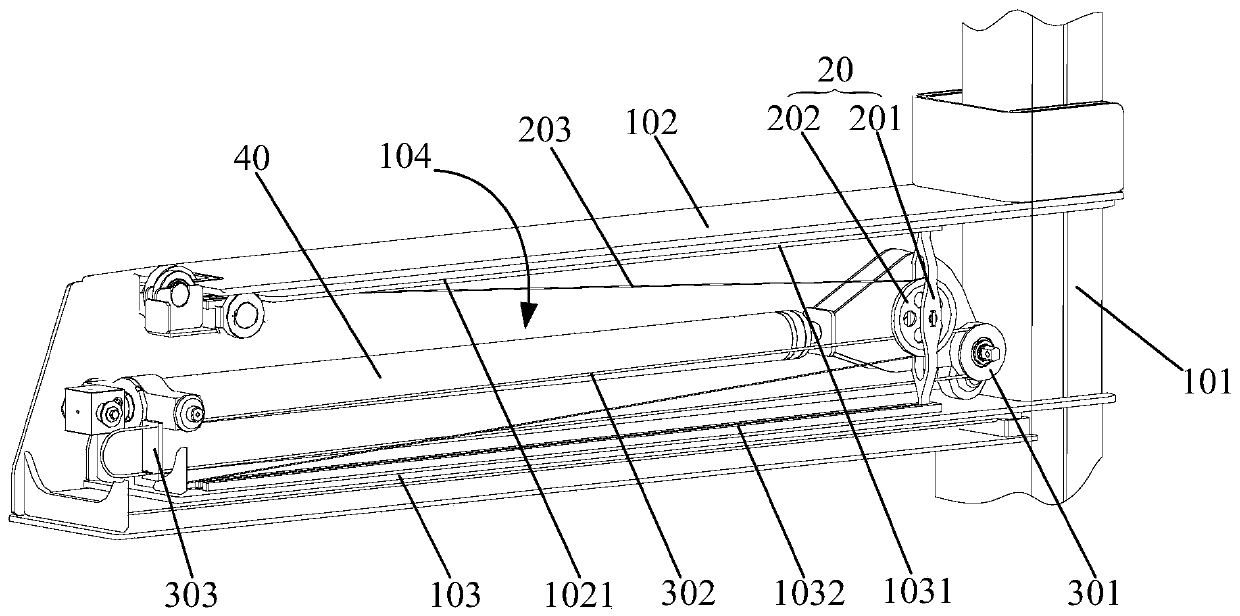

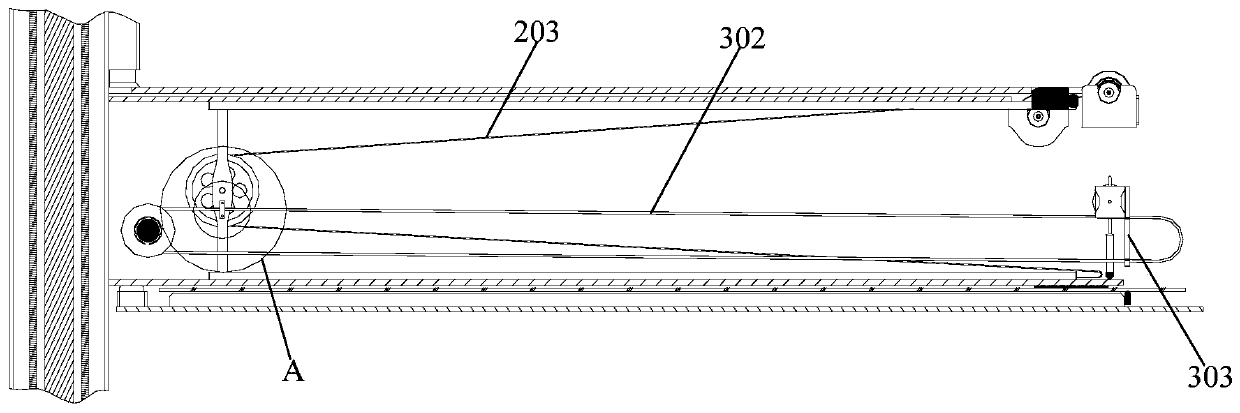

[0058] Such as figure 2 and image 3 As shown, the difference from Embodiment 2 is that the driving mechanism includes: a cable roller 301, which is arranged at one end of the outrigger assembly close to the movable roller assembly 20, and is relatively fixed with the outer outrigger 102; On the cable roller 301, and fixedly connected with the roller bracket 201; the front cable fixing seat 303 is arranged on the end of the leg assembly away from the cable roller 301, and is relatively fixed with the outer leg 102, and the front cable fixing seat 303 is used for The cable 302 is locked or unlocked by cooperating with the locking member; wherein, when the cable 302 is in an unlocked state and the cable 302 is driven, the cable 302 can drive the movable roller assembly 20 to slide back and forth relative to the inner leg.

[0059] The driving mechanism includes a cable roller 301, a cable 302 and a front cable fixing seat 303, wherein the cable roller 301 is arranged on the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com