Rotary turnover device and method for heavy product

A product and heavy-duty technology, applied in the field of heavy-duty product rotary turning device, can solve the problems of poor safety and low turning efficiency, and achieve the effect of improving efficiency, high versatility, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

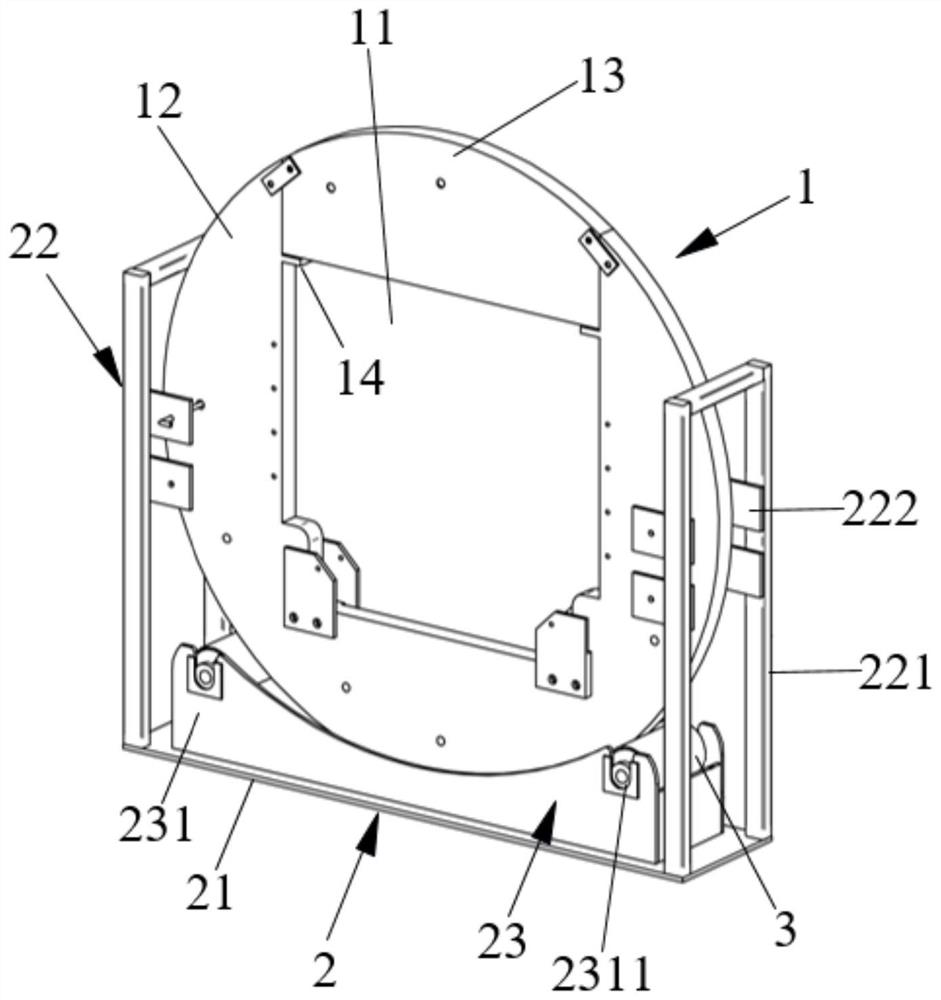

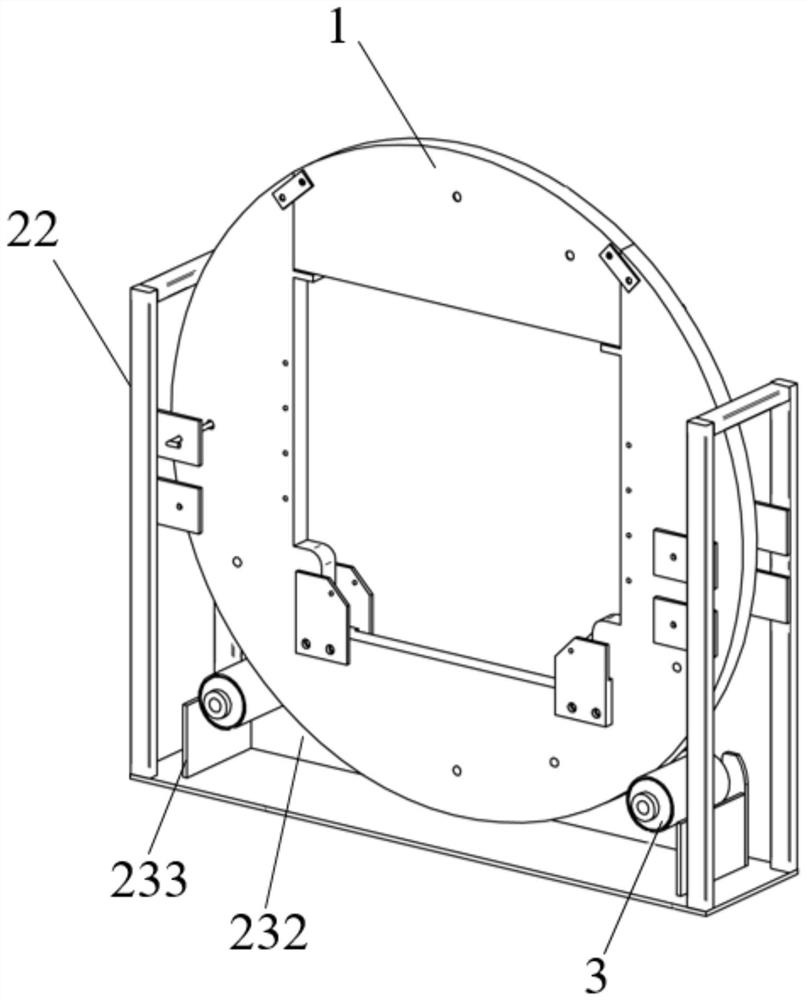

[0036] A specific embodiment of the present invention, such as Figure 1-Figure 2 As shown, a heavy-duty product rotary turning device is disclosed, including a round wheel assembly 1, a support frame 2 and a plurality of idler rollers 3, and a plurality of idler rollers 3 are arranged on the support frame 2 and are rotatably connected with the support frame 2, The round wheel assembly 1 is set in the support frame 2 and is located above a plurality of idler rollers 3. The cylindrical surface of the round wheel assembly 1 is in contact with the cylindrical surface of the idler roller 3. The center of the round wheel assembly 1 is provided with a through hole 11. The heavy product is arranged in the through hole 11 of the round wheel assembly 1, and when the supporting roller 3 is rotated, the round wheel assembly 1 drives the heavy product to turn over.

[0037] Compared with the prior art, the heavy-duty product rotary flipping device provided by this embodiment cooperates wi...

Embodiment 2

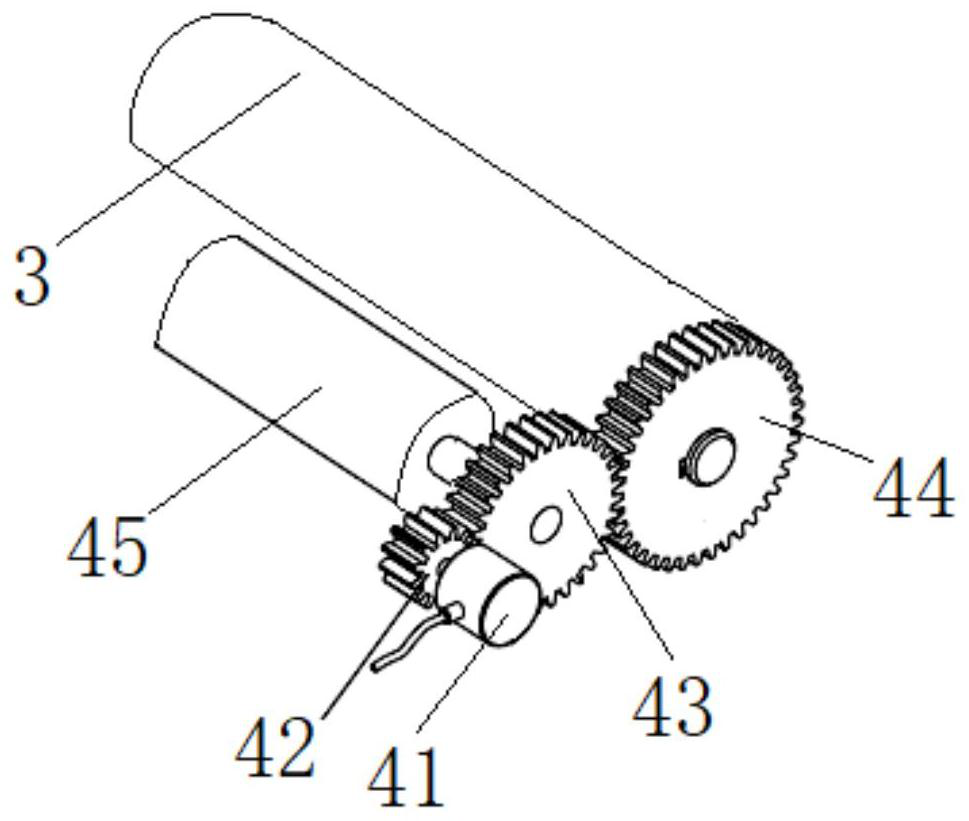

[0051] Another specific embodiment of the present invention, such as Figure 3-Figure 4 As shown, a heavy-duty product rotary turning device is disclosed. Since the outer surface of the heavy-duty product is subjected to other operations (such as grinding, puttying, and painting), quality inspection is required. In order to improve the efficiency of quality inspection , the first choice is to quickly scan and inspect heavy products in the rotating state. When abnormalities are found, the rotation needs to be stopped. Therefore, heavy products need frequent switching between dynamic and static during quality inspection. In order to achieve this purpose and improve the automation of turning heavy products, on the basis of Embodiment 1, a power drive unit is added to the idler roller 3 .

[0052] The power drive unit comprises a first drive motor 41, a first transmission wheel 42, a second transmission wheel 43 and a third transmission wheel 44, the first transmission wheel 42 is...

Embodiment 3

[0072] Another specific embodiment of the present invention discloses a method for rotating a heavy-duty product. The steps include:

[0073] Step S1: Place the heavy product to be turned over in the round wheel assembly 1 .

[0074] Step S2: The power drive unit sets the first transmission wheel 42, the second transmission wheel 43 and the third transmission wheel 44 for transmission, and controls the movement of the second transmission wheel 43 through the linear motor 45 to complete the connection between the second transmission wheel 43 and the first transmission wheel. 42 and the third transmission wheel 44 meshing and non-engaging state switching, and then realize the switching of the movement and stop state of the idler roller 3, and realize the continuous or intermittent turning over of heavy products.

[0075] When needing to stop, the linear motor 45 drives the displacement of the second transmission wheel 43, so that the second transmission wheel 43 is disengaged fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com