Thick section and narrow gap T-shaped welding method

A welding method and narrow gap technology, applied in welding equipment, welding accessories, characteristics of welding rods, etc., can solve the problems of irregular welding bead, difficult welding bead planning, and lack of fusion between passes, so as to reduce the amount of welding and reduce welding Number of bead cleanings, avoiding the effect of unfused between welds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0058] As a preferred embodiment of the present invention, this embodiment discloses:

[0059] Thick-section narrow-gap T-type welding method is characterized in that: comprising the following steps:

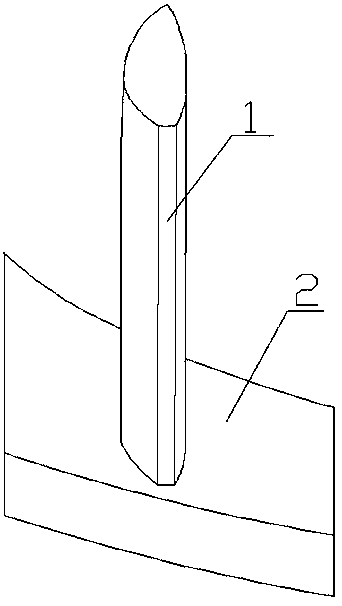

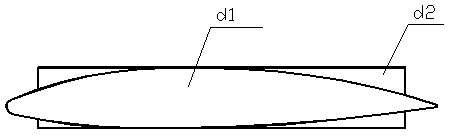

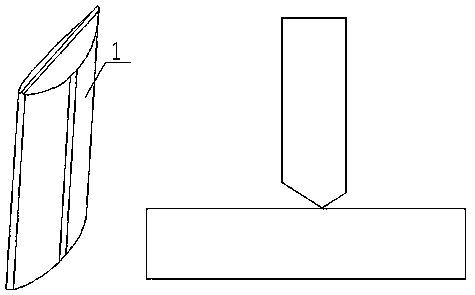

[0060] Groove design steps: process the heterosexual thick plate within 60mm above the welding end into a rectangular structure, the width of the rectangular structure is not less than the maximum width of the special-shaped thick plate 1; the welding surface of the rectangular structure is an oblique welding surface with a certain slope 4 , forming a Type I narrow gap groove structure, the gap between the root of the Type I narrow gap groove and the planar thick plate 2 is less than 16mm, and the gap between the upper end of the Type I narrow gap groove and the planar thick plate 2 is less than 20mm ; Open a conventional K-shaped bevel at both ends of the special-shaped thick plate 1 with a certain length, and leave a certain gap between the K-shaped bevel and the I-like narrow...

Embodiment 2

[0067] As another preferred embodiment of the present invention, with reference to the attached Figure 1-6 , this example discloses:

[0068] Thick-section narrow-gap T-type welding method is characterized in that: comprising the following steps:

[0069] Groove design steps: process the heterosexual thick plate within 60mm above the welding end into a rectangular structure, the width of the rectangular structure is not less than the maximum width of the special-shaped thick plate 1; the welding surface of the rectangular structure is an oblique welding surface with a certain slope 4 , forming a Type I narrow gap groove structure, the gap between the root of the Type I narrow gap groove and the planar thick plate 2 is less than 16mm, and the gap between the upper end of the Type I narrow gap groove and the planar thick plate 2 is less than 20mm ; Open a conventional K-shaped bevel at both ends of the special-shaped thick plate 1 with a certain length, and leave a certain gap...

Embodiment 3

[0076] As another preferred embodiment of the present invention, with reference to the attached Figure 1-11 , this example discloses:

[0077] The use of robots 113 is the direction of the future manufacturing industry. For the robot 113 welding of special-shaped thick plates and ultra-thick plates, it is necessary to improve the welding quality and efficiency of the arc welding robot 113. Therefore, by changing the welding structure of the product, we change the welding groove of the thick plate and the ultra-thick plate, and carry the new welding technology on the arc welding robot 113 to reduce the welding amount of the ultra-thick section structural parts, thereby increasing the arc welding robot 113. The welding efficiency has opened up a new field of intelligent welding for the arc welding robot 113 in the hydropower industry of power generation equipment.

[0078] Narrow gap gas shielded welding welding technology is a new type of welding technology, which mainly has...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com