Tool used for rapid assembly of JW4G frame

A framework and fast technology, applied in auxiliary devices, manufacturing tools, metal processing, etc., can solve problems such as welding deformation and difficult size control, and achieve the effect of preventing framework deformation, improving productivity, and ensuring group quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

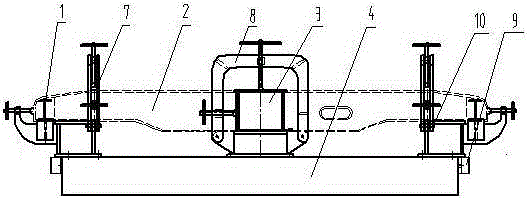

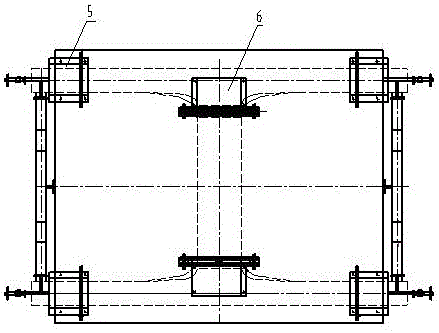

[0029] As shown in the figure, the patent’s tooling for JW4G frame fast assembly is characterized by: including the main platform, four-corner height platform, middle height platform, adjustment and compression device 1, adjustment and compression device 2, End beam positioning stops and pins.

[0030] Two sets of four-corner height platforms are set opposite to each other at the four corners of the main platform, which are used to position and carry the two side beams in the JW4G frame.

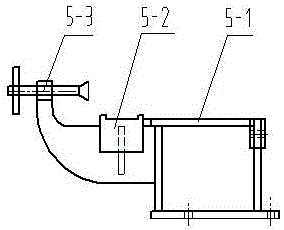

[0031] The four-corner height platform includes the first platform, the side beam positioning block, the side beam front and rear adjustment device and the end beam positioning plate; the first platform is used to connect the main platform and support the side beam; the side beam positioning block is arranged on the first platform for Limit the side beams so that the two side beams are parallel to each other and the distance matches the length of the beam; the front and rear adjustment devices...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com