Guide wheel welding assembling tool

A guiding wheel and pairing technology, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as scrapping, insufficient strength, large deformation of web plates, etc., to ensure the quality of pairing and prevent welding deformation , Guarantee the effect of positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

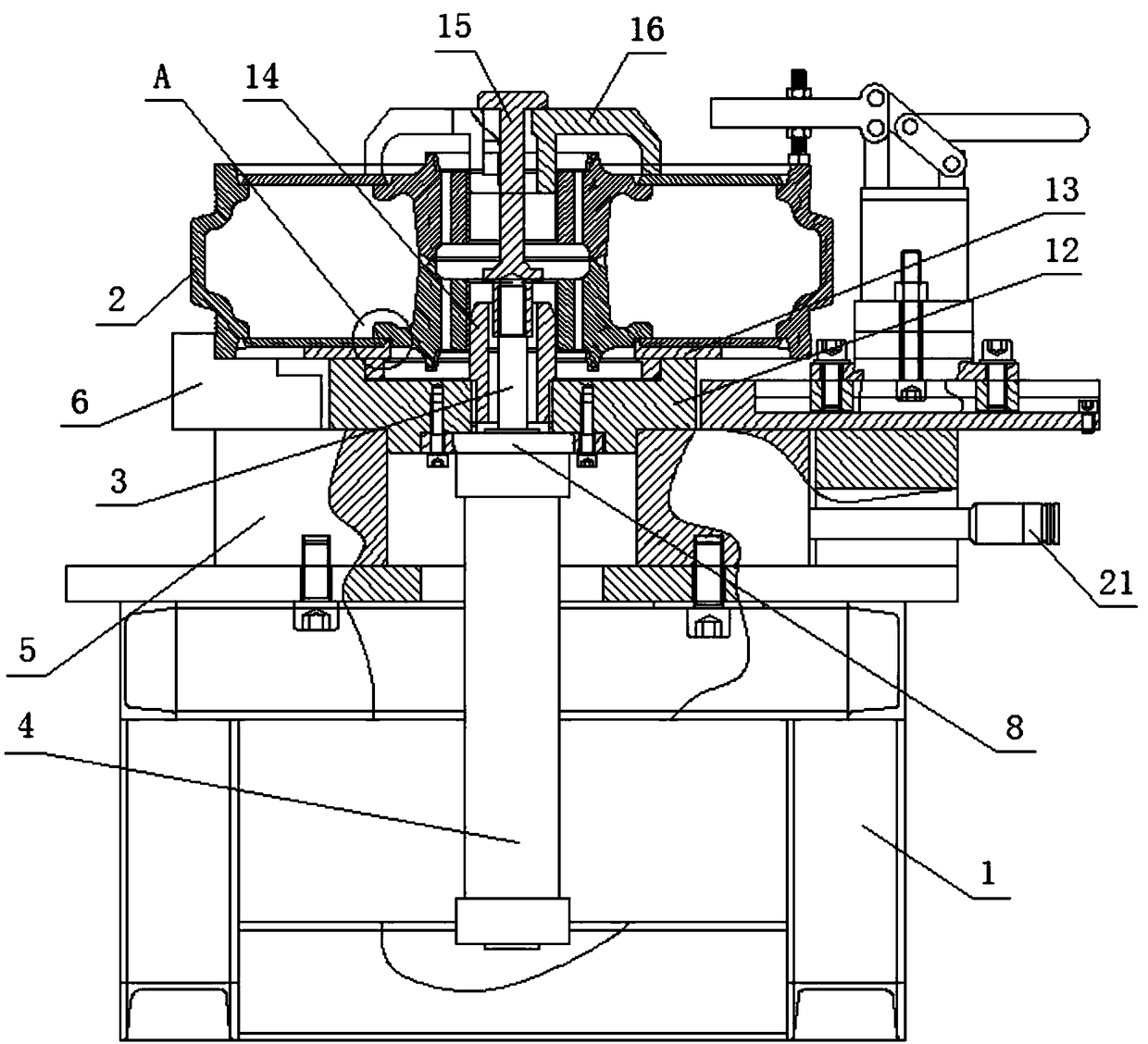

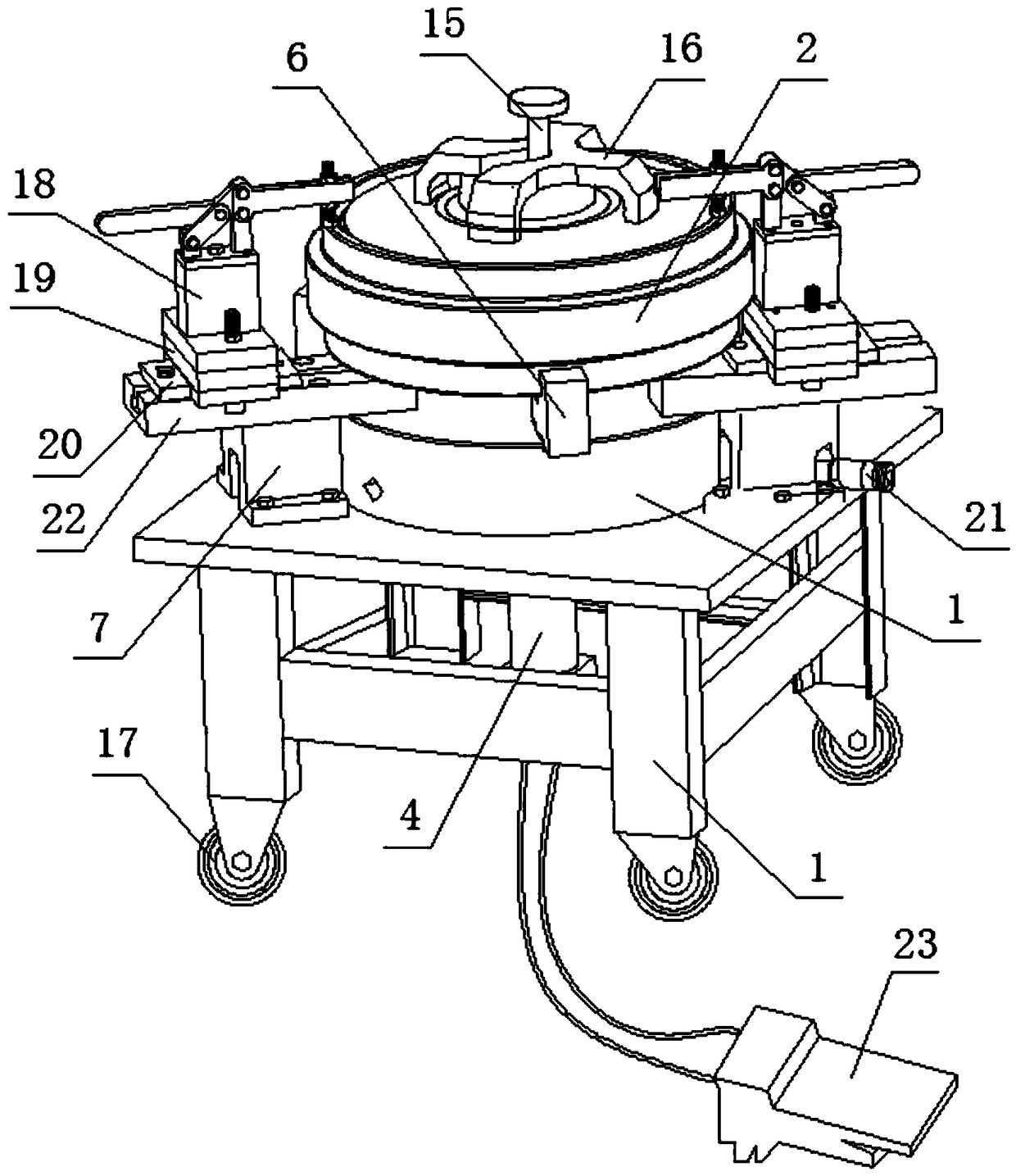

[0033] Such as Figure 1 to Figure 9 The shown guide wheel welding assembly tooling includes a reference platform, a positioning mechanism and a pressing mechanism. The reference platform includes a bracket 1 with a universal wheel 17 installed at the bottom, and the positioning mechanism includes a positioning plate 12, a tray 13, and a mandrel 14 And three-jaw chuck 5, the pressing mechanism comprises cylinder 4, cylinder flange 8, cylinder briquetting block 15, pressure claw 16 and fast pressing device, and the table top center of support 1 is provided with through hole, and three-jaw chuck 5 passes through Bolts are installed on the outer circumference of the through hole in the center of the table top of the bracket 1. The three-jaw chuck 5 is controlled by the wrench extension rod 21. The positioning plate 12 is arranged on the three-jaw chuck 5. There is a gap between the positioning plate 12 and the three-jaw chuck 5. Cooperate, the tray 13 is arranged on the positioni...

Embodiment 2

[0035] On the basis of Embodiment 1, the cylinder 4 is controlled by the pedal 23, which is convenient for controlling the cylinder 4. Two grooves are symmetrically arranged on the peripheral surface of the mandrel 14, which is convenient for the disassembly and assembly of the mandrel 14.

Embodiment 3

[0037] On the basis of Embodiment 1, the quick pressing mechanism 18 can adopt a corner cylinder or a hydraulic oil cylinder.

[0038] working principle:

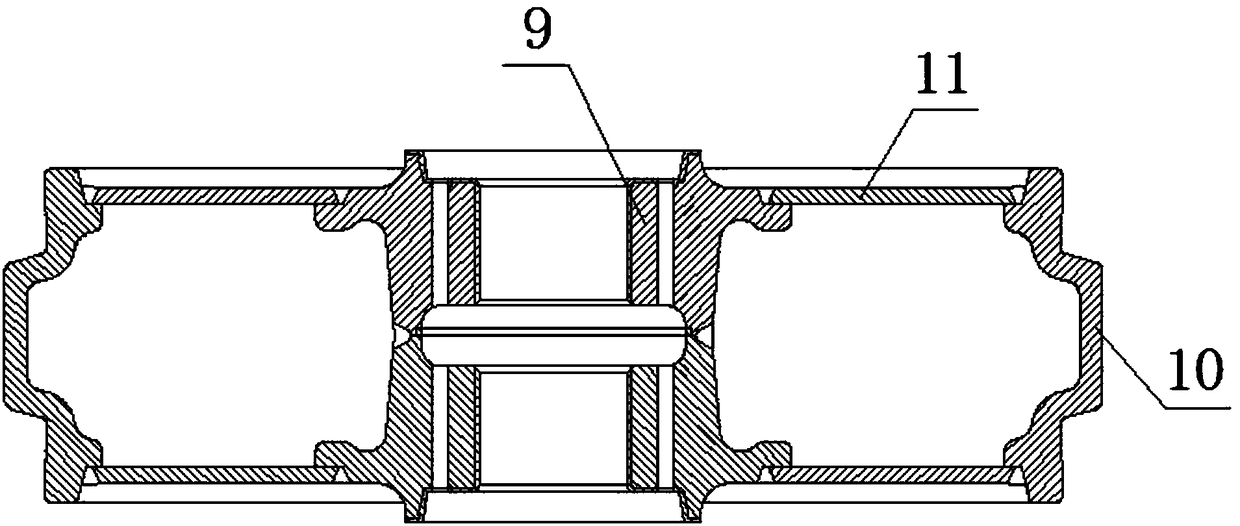

[0039] The wrench extension rod 21 controls the movement of the claws 6 of the three-jaw chuck 5, and the gap between the positioning plate 12 and the three-jaw chuck 5 is matched, and the claws 6 go deep into the groove of the positioning plate 12, limiting the rotation of the positioning plate 12 At the same time, the guide wheel 2 is clamped, and the gap between the tray 13 and the positioning plate 12 is matched to prevent the left and right and up and down movements of the tray 13, and play the role of fixing the lower web 11, ensuring that the lower web 11 is concentric with the hub 9, and the mandrel The 14 thread is installed on the positioning plate 12, which is easy to replace, and the surface is heat-treated to improve wear resistance. The distance between the two limit bosses on the cylinder pressure block 15 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com