Cantilever and radials type titanium alloy casing deformation control method and device

A technology of welding deformation and control method, applied in the field of machining, can solve the problems of low machining accuracy of parts, and achieve the effect of reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

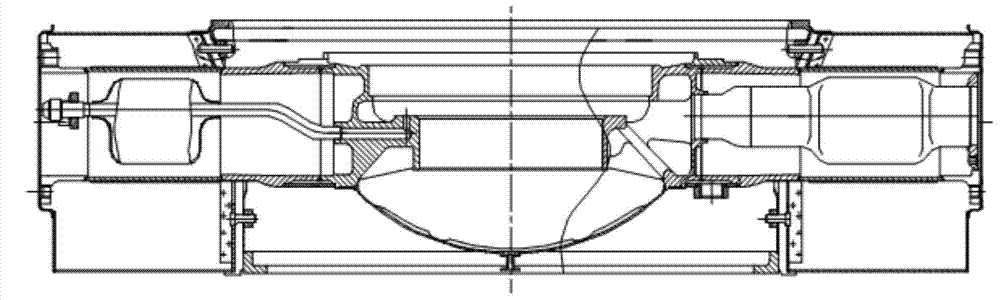

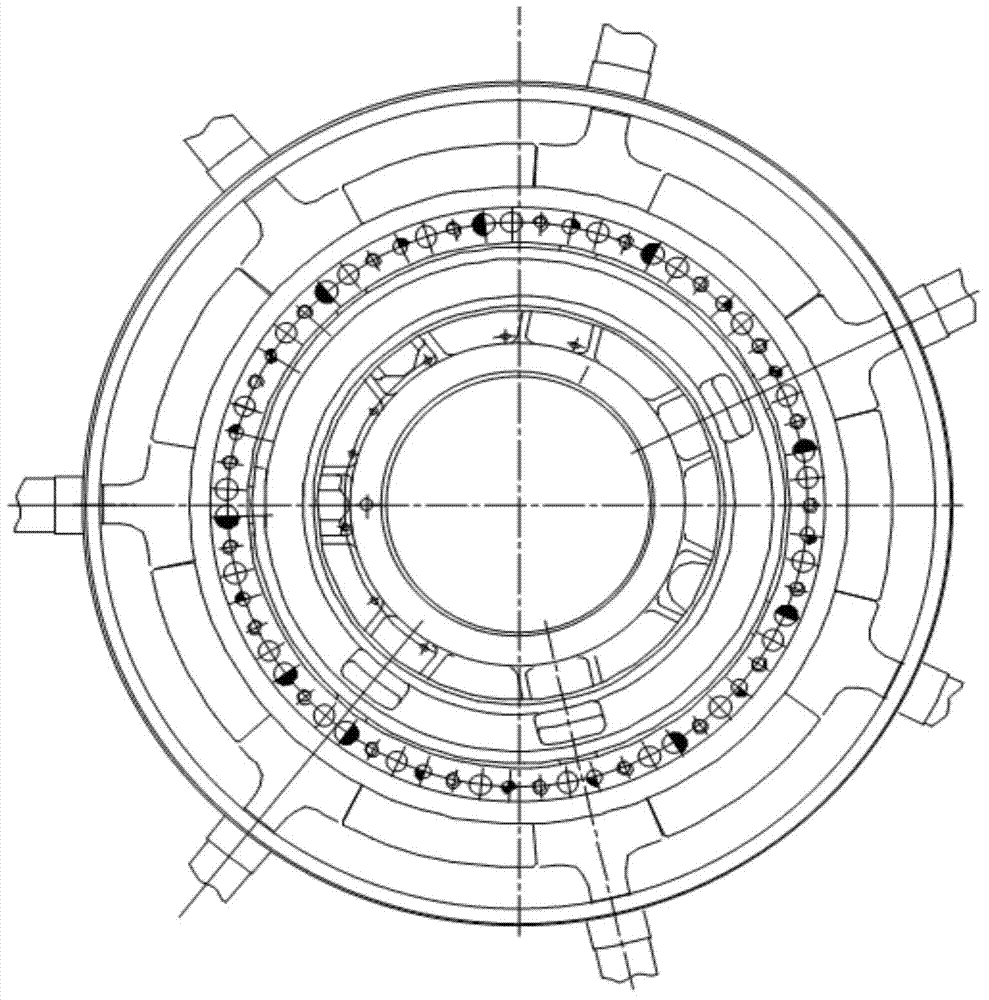

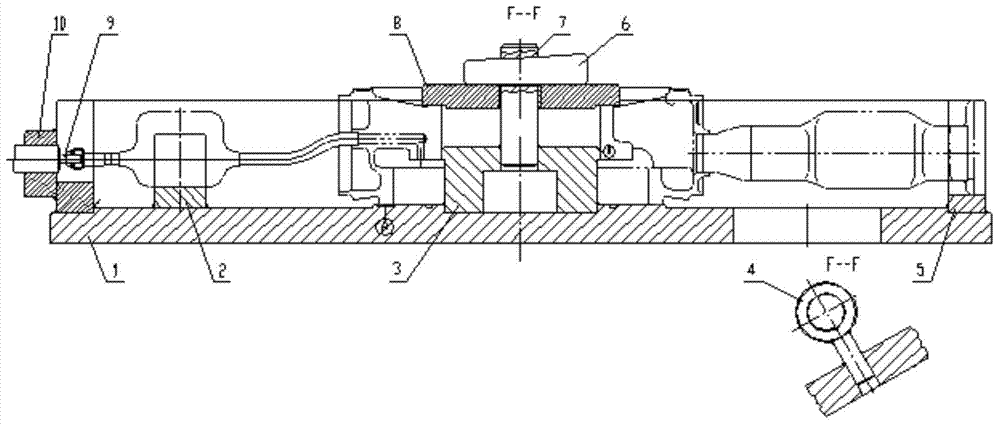

[0023] This embodiment provides a method for controlling the welding deformation of a cantilever and radial plate type titanium alloy casing, which is characterized in that: the method for controlling the welding deformation of a cantilever and radial plate type titanium alloy casing is adopted from the inside to the outside, from the middle to both sides 2. The overall welding sequence from the inner layer to the outer layer. In order to eliminate the welding stress, stress relief heat treatment is arranged after welding. Due to the number of layers and welding parts of the parts, the stress during the welding process is relatively large. After the inner layer is welded, the intermediate The purpose of heat treatment is to correct the precise thermal shape correction, remove the welding stress in the early stage, and avoid the stress release at the final heat treatment. The heat treatment fixture is as follows: image 3 , 4 As shown, the accumulation of welding deformation in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com