Large length-width ratio hollow-out type fixing guide vane

A technology for fixing guide vanes and water turbines, which is applied in the fields of hydropower generation, mechanical equipment, engine components, etc., can solve the problems of increasing manufacturing and installation costs, high costs, and heavy weight of the fixed guide vanes by integral casting, and achieves reduction of difficulty, weight, and cost. The effect of reducing material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

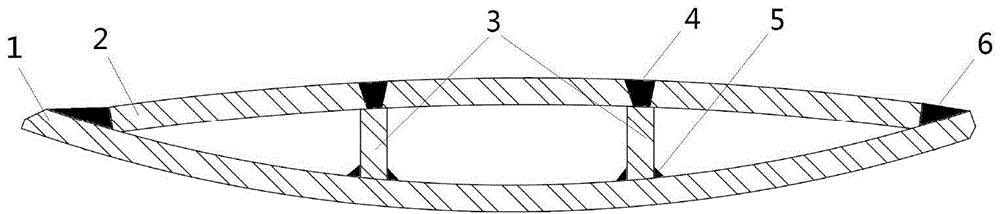

[0014] Such as figure 1 As shown, the present invention provides a novel large-length-width-ratio hollow fixed guide vane with simple and reasonable structure, good rigidity, high strength, material saving, and easy manufacture. Compared with the hollow fixed guide vane, it includes an upper petal body 2, a lower petal body 1 and several ribs 3, and is characterized in that: a rib 3 is arranged between the upper petal body 2 and the lower petal body 1, and the rib plate 3 and the lower petal body Body 1 is welded and connected by fillet weld 5, and the fillet of fillet weld 5 is not less than one-third of the thickness of the thinnest base metal. Rib 3 and upper petal body 2 are welded and connected by plug weld 4, and plug weld 4 The number of columns is the same as the number of ribs 3, and the number of plug welds 4 in each column is not less than 2 / m. The upper petal body 2 and the lower petal body 1 are connected by groove weld 6, and the groove weld 6 The depth of the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com