Laser welding method of nuclear fuel storage framework bush square tube and small base plate

A storage grid and storage sleeve technology is applied in the field of laser welding of the storage sleeve square tube and the small bottom plate of the nuclear fuel storage grid, which can solve the problems of deformation quality and forming, high labor intensity, low efficiency, etc., so as to solve the welding deformation , the effect of reducing labor intensity and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

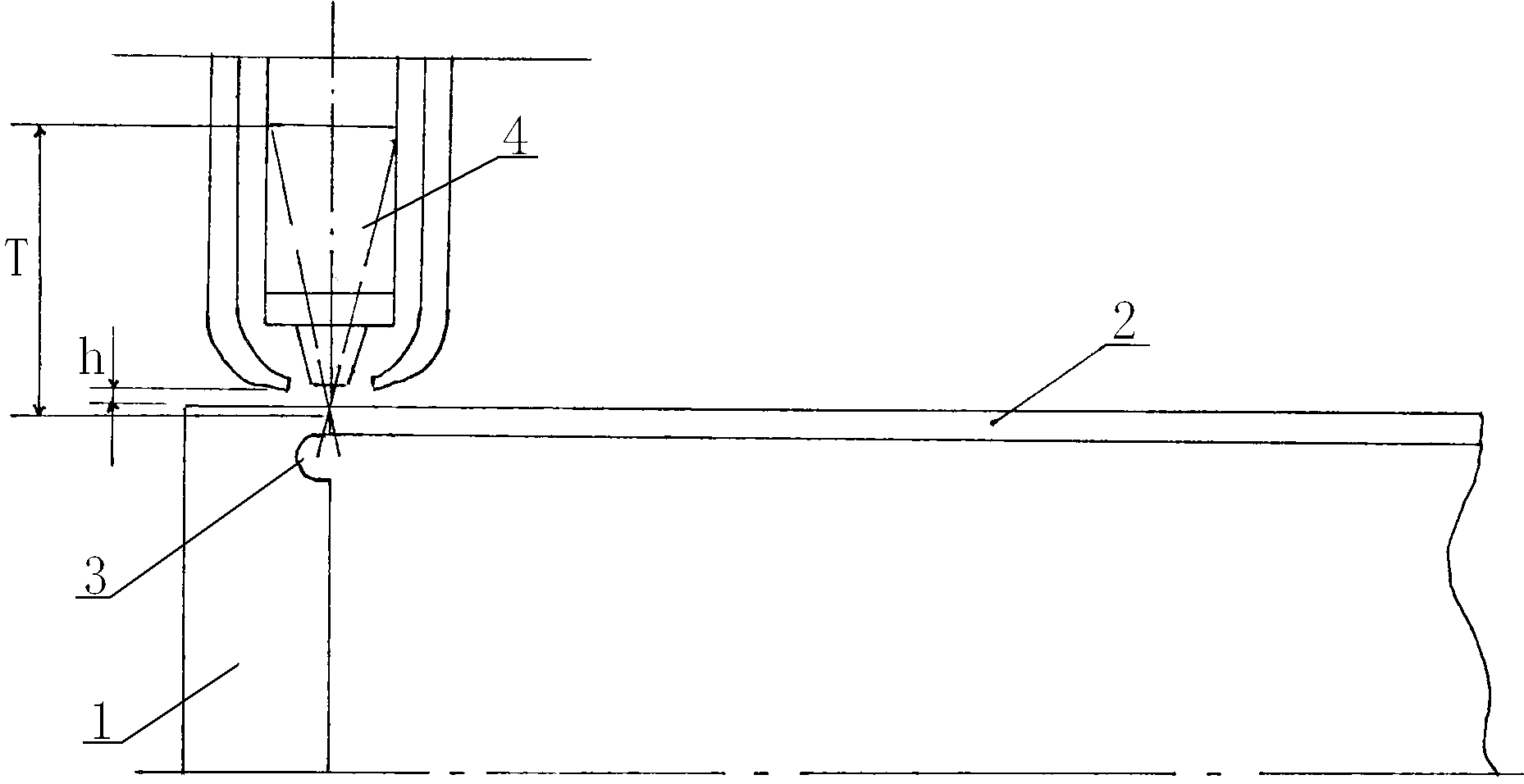

[0012] Refer to attached figure 1 , the nuclear fuel storage grid storage casing square tube and the laser welding method of the small bottom plate are as follows:

[0013] Firstly, the arc groove 3 of R1.5mm~R2mm is processed at the distance of 2mm from the periphery of the small bottom plate 1, and R is the radius (see the appendix of the instruction manual). figure 1 ) (Here, to avoid stress concentration, it cannot be processed into a rectangular groove), and the arc groove 3 is 3-4mm deep. Then install it on the jig to form a butt joint with the square tube 2 of the nuclear fuel storage grid storage sleeve. The joint gap between the two should be strictly controlled within less than 0.1mm, and the straightness of the weld should be less than 0.5mm. The laser welding power is adjusted to 2500W, the welding focal point T is adjusted to 98.5-99mm, that is, the height distance H between the gas blowpipe 4 of the welding head and the welding seam is controlled between 1.5-2mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com