Assembly tool of inner ring rib cylindrical shell pressure resisting structure and assembly method thereof

A pressure-resistant structure and assembly tooling technology, applied in the direction of assembly machines, auxiliary devices, manufacturing tools, etc., can solve problems such as welding deformation and residual stress, achieve a high degree of automation, fast guidance and positioning, solve welding deformation and participate in stress problem effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Specific embodiments of the present invention will be described below.

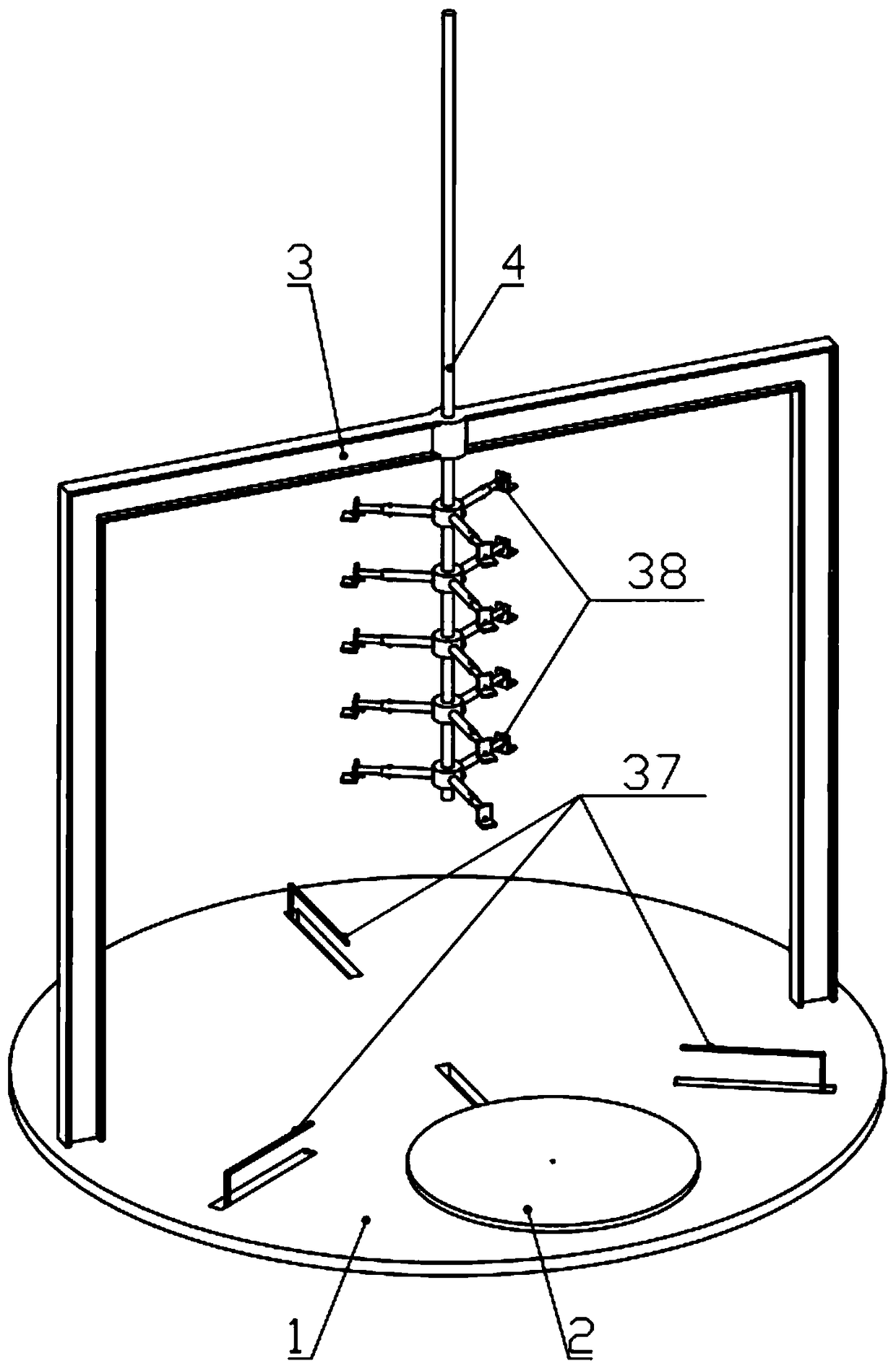

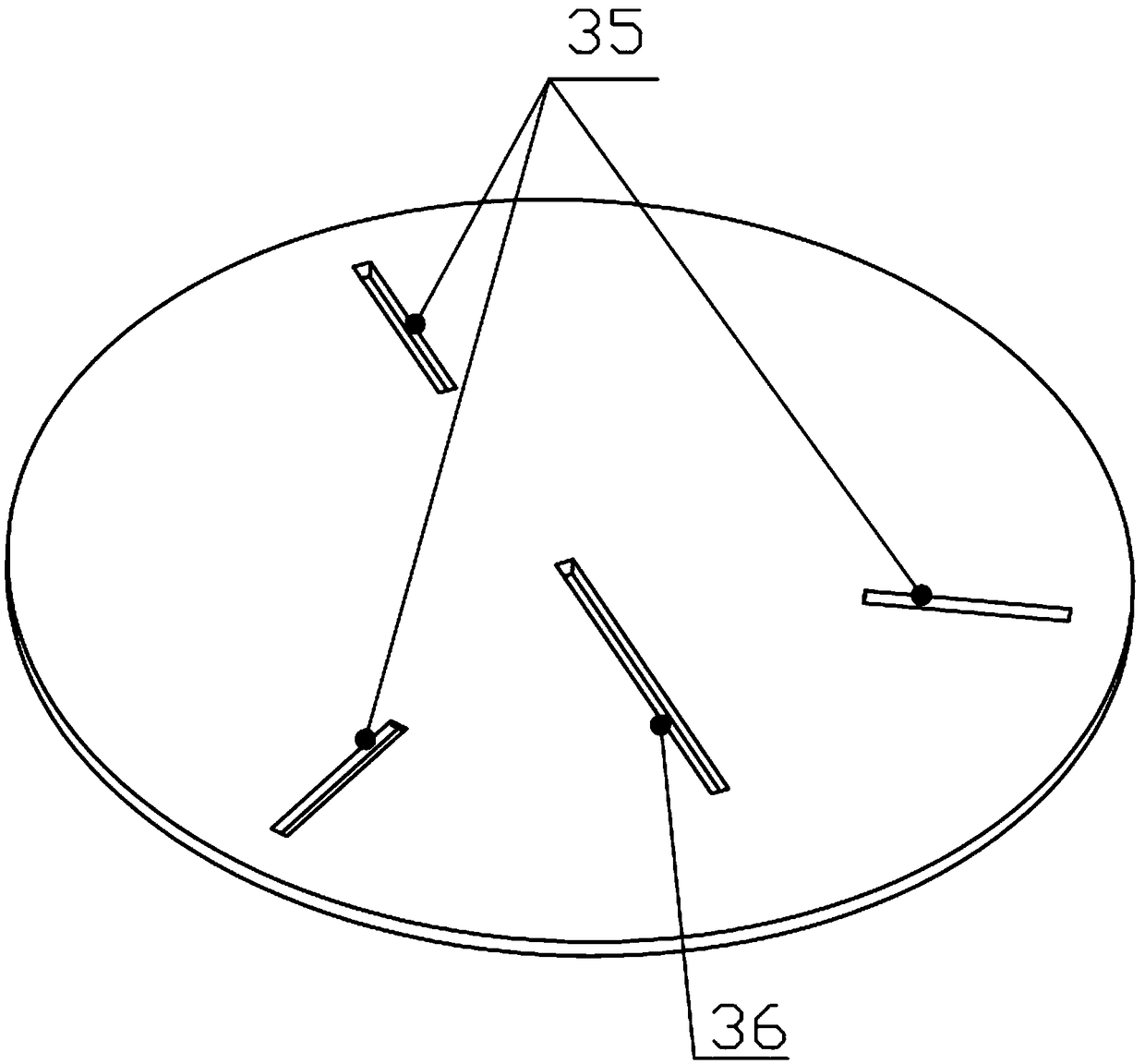

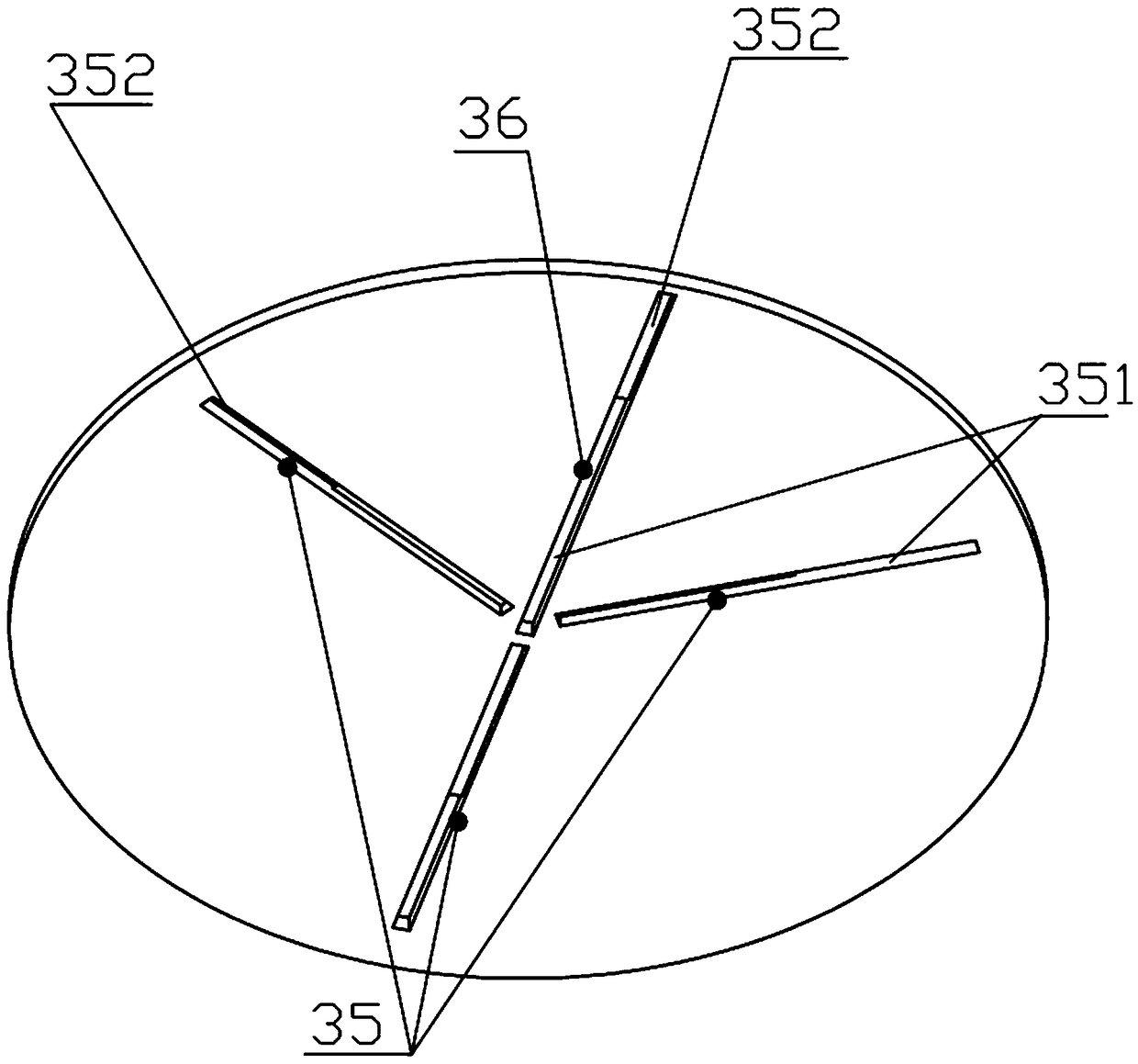

[0043] Such as figure 1 As shown, an assembly tooling for the pressure-resistant structure of an inner ribbed cylindrical shell includes a working platform 1, a flatbed truck 2 for loading the cylindrical shell, a frame 3, a suspension shaft 4, a positioning mechanism 37 for clamping and positioning the cylindrical shell, and a For the guiding mechanism of the transfer cylindrical shell and the rib tooling for assembling the annular ribs, the flatbed car 2 is movably arranged on the surface of the working platform 1, and a hole for matching the connecting piece 22 is opened on the flatbed car 2. The hole is a rectangular hole. The suspension shaft 4 is installed through the frame 3, and a plurality of rib tooling is installed from top to bottom on the outer periphery of the suspension shaft 4 facing the working platform 1 and protruding from the frame 3. The positioning mechanism 37 and the guiding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com