Quick assembling and welding fixture used for side beams of engineering car framework

A side beam, fast technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of controlling welding deformation, difficult size, etc., to save time, improve productivity, and ensure the effect of group pair quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

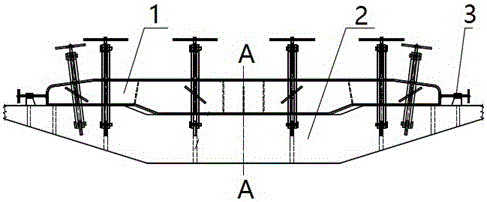

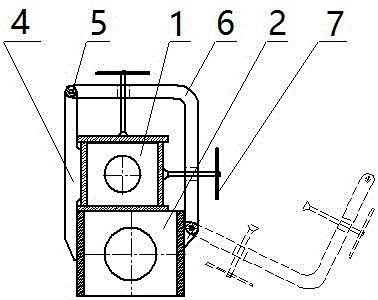

[0030] As shown in the figure, a tooling for rapid assembly and welding of frame side beams in this patent includes a main frame 2, a positioning baffle 4, a first pressing device 6, a second pressing device 3 and a pin shaft 5 .

[0031] The upper part of the main frame 2 is a plane, and the middle part of the plane is provided with a concave part matching with the lower protrusion of the side beam 1; the concave part is used for positioning and carrying the side beam 1.

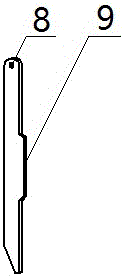

[0032] The upper part of the positioning baffle 4 is provided with a first connecting hole 8, and the side is provided with a rib 9; the width of the rib 9 is equal to the horizontal distance from the outer side of the vertical plate of the side beam 1 to the outer edge of the upper cover.

[0033] The first pressing device 6 includes a frame body 12, a vertical lead screw 11 and a horizontal lead screw 13; the frame body 12 is a bent rod-shaped member, and the bent rod-shaped member includes a horizontal p...

Embodiment 2

[0041] When using the tooling for fast assembly and welding of frame side beams as described in Embodiment 1 to carry out side beam 1 pairing operation, the first step is the vertical plate and partition of the prefabricated side beam, that is, the vertical plate and The partition points are fixed as a whole; the second step is to assemble and weld the lower cover plate of the side beam, the vertical plate and the partition plate, specifically, first place the lower cover plate in the depression of the main frame 2, and make the lower The left side of the plate fits the rib 9 of the positioning baffle plate 4, and then the prefabricated vertical plate and partition plate are placed on the lower cover plate, and the horizontal lead screw 2 of the second pressing device 3 at the two ends of the main frame 2 is adjusted. 14. Make the vertical plate coincide with the center of the lower cover plate; then connect each first pressing device 6 with the corresponding positioning baffle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com