Copper alloy conducting bar and end ring for high-power frequency-adjustable speed-adjustable asynchronous traction motor and preparation method thereof

A traction motor and high-power technology, applied in the field of preparation of bars and end rings, can solve the problems of incompatibility with the design requirements of new traction motors, and achieve the effects of improved electrical regulation performance, reduced resistivity difference, and easy conductivity performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

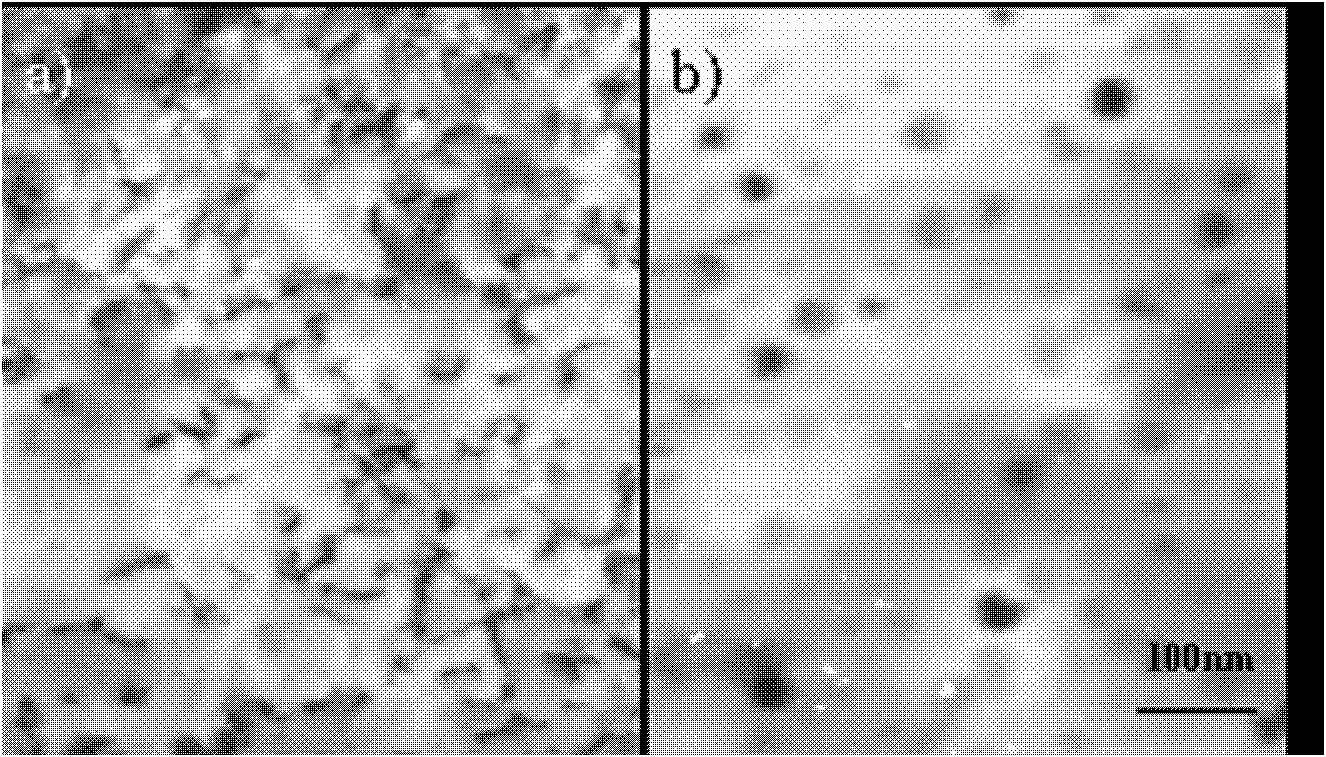

Image

Examples

Embodiment 1( 100 ):10.0%,0.5%,0.1%,,-----890℃----450℃/5h,, to 1150℃ to ;5mm,1250℃,6mmCu-10Zr to 。 preparation 1。350km/h。, and ,ρ150℃ to (5.02±0.05)×10-6Ω.cm, and , to ,350℃≥320Mpa。ZL99101984.9。()1 and comparative Embodiment 2

[0019] Example 1 Copper alloy guide bar for high-speed train traction motor rotor Composition (mass percentage) of copper alloy guide bar: 10.0% zinc, 0.5% chromium, 0.1% zirconium, and the rest is copper. Ingredients-medium frequency induction melting-semi-continuous casting-casting Ingot homogenization - hot extrusion - 890 ° C online quenching - cold drawing - straightening - shearing - 450 ° C / 5h aging, after the copper is completely melted, the temperature is lowered to 1150 ° C and then the zinc ingot is added to the copper melt; chromium The particles smaller than 5mm are wrapped with thin copper foil and pressed into the copper melt at 1250°C, and the zirconium is inserted into the copper melt at the upper part of the crystallizer in the form of Cu-10Zr intermediate alloy filaments with a diameter of about 6mm. The main properties of the prepared bars are listed in Table 1. The copper alloy guide bar of the present invention has been used in the rotor guide bar of a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com